IM 817-7

10 www.DaikinApplied.com

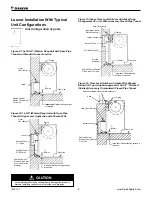

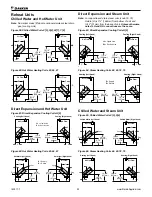

Typical Installation Methods

If the fresh air opening has not yet been made, see

locations and the job-specific plans for the exact location.

Follow local codes.

Cut the wall opening so that it is slightly larger than the

louver being installed. For dimensions, see

. If

the opening is already there, measure to be sure there is

a minimum of 3/8ʺ (9mm) clearance around all sides. For

masonry installations, a lintel must be installed above all

louvers.

In thick wall applications, the portion of the wall

between the louver and the unit is the outside air

plenum. Line this plenum area with 3/8ʺ (9 mm) mortar

or other suitable material. In some applications, the

job specifications require a metal sleeve connection

between the louver and the unit. If using such a sleeve,

properly caulk it to ensure a weather-tight seal. This

is critical in preventing freeze-ups, cold drafts, and air

infiltration. Be sure the wall is smooth, square, and

provides a suitable mating surface.

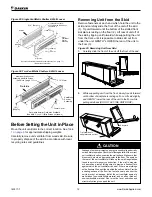

Table 2: Recommended Wall Openings For Wall Louvers

B

C

Recommended

Wall Openings

For Wall

Louvers

Maximum Number of

VentiMatic Shutters

Which Can Be

Mounted On Stan-

dard Louver

VentiMatic

Shutter(s)

Air Capacity

Maximum

Length Height

24

ʺ

Shutter

36

ʺ

Shutter

cfm

L/s

24"

(610)

27"

(659)

24

5

⁄

8

"

(613)

10

7

⁄

8

"

(267)

1

0

500

236

36"

(914)

39"

(991)

36

5

⁄

8

"

(918)

10

7

⁄

8

"

(267)

0

1

750

354

48"

(1219)

51"

(1295)

48

5

⁄

8

"

(1222)

10

7

⁄

8

"

(267)

2

0

1000

472

60"

(1524)

63"

(1600)

60

5

⁄

8

"

(1527)

10

7

⁄

8

"

(267)

1

1

1250

590

72"

(1829)

75"

(1905)

72

5

⁄

8

"

(1832)

19

7

⁄

8

"

(495)

0

2

1500

708

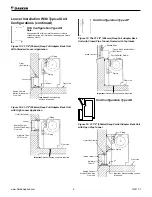

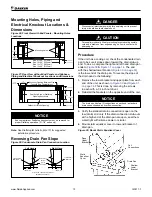

Before setting the louver, construct a sloping, sealed

cement mortar base to drain unwanted moisture to the

outside, (see

). Be sure the mortar base is 1ʺ

(25mm) thick at the unit and tapers toward the louver.

The mortar at the unit also acts as a backing against

which the open cell gasket of the unit itself can seal.

This is critical in preventing water leaks and air leaks

under the unit. Be sure the sealed cement mortar base is

smooth and flush with the interior wall.

If it is not possible to construct a sloping mortar base,

then field-supplied flashing is required. See

The flashing should terminate flush with the exterior of

the building. Place a bead of caulk under the flashing to

prevent moisture from wicking back to the unit. Do not

caulk the joint between the louver and the flashing. This

joint is designed to let unwanted moisture escape.

Figure 17: Typical Louver Installation with Sloping Sealed

Cement Mortar Base

Unit Gasket

Sealed Cement

Mortar;

Pitch Away

From Unit

Floor

Wall

Unit

Louver

No

Caulk

1" (25mm)

Figure 18: Typical Louver Installation with Flashing

Louver

No

Caulk

Unit Gasket

Wall

Unit

1" (25mm)

Floor

Caulk

(By

Others)

Flashing

(By

Others)

CAUTION

Personal injury hazard. Wear protective gloves to avoid possible cuts

and abrasions from exposed edges. Avoid contact with sharp edges.

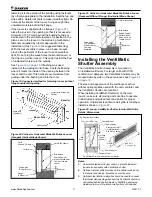

. Before setting the louver, be sure the drain lip

(vertical louver) are at the bottom, horizontal louver

blades face down and the bird screen is towards the

unit. See

and

. Place

a heavy bead of caulk along the top and the two vertical

sides of the louver, leaving the bottom uncaulked so that

if moisture gets into the area between the louver and the

unit, it can drain to the outside, unrestricted.

If the louver is supplied with flanges, (

an additional bead of caulk on the inside of the top and

side flanges that come in contact with the building facade.

Do not caulk the bottom flange. Place the louver in the

opening and push it tight against the supplied building,