IM 817-7

40 www.DaikinApplied.com

NOTICE

Typical conditions - 95ºF ambient, 75 psig suction, 285 psig head

pressure, 6 - 7º superheat, 15ºF subcooling

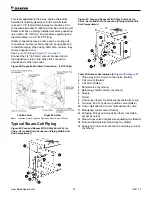

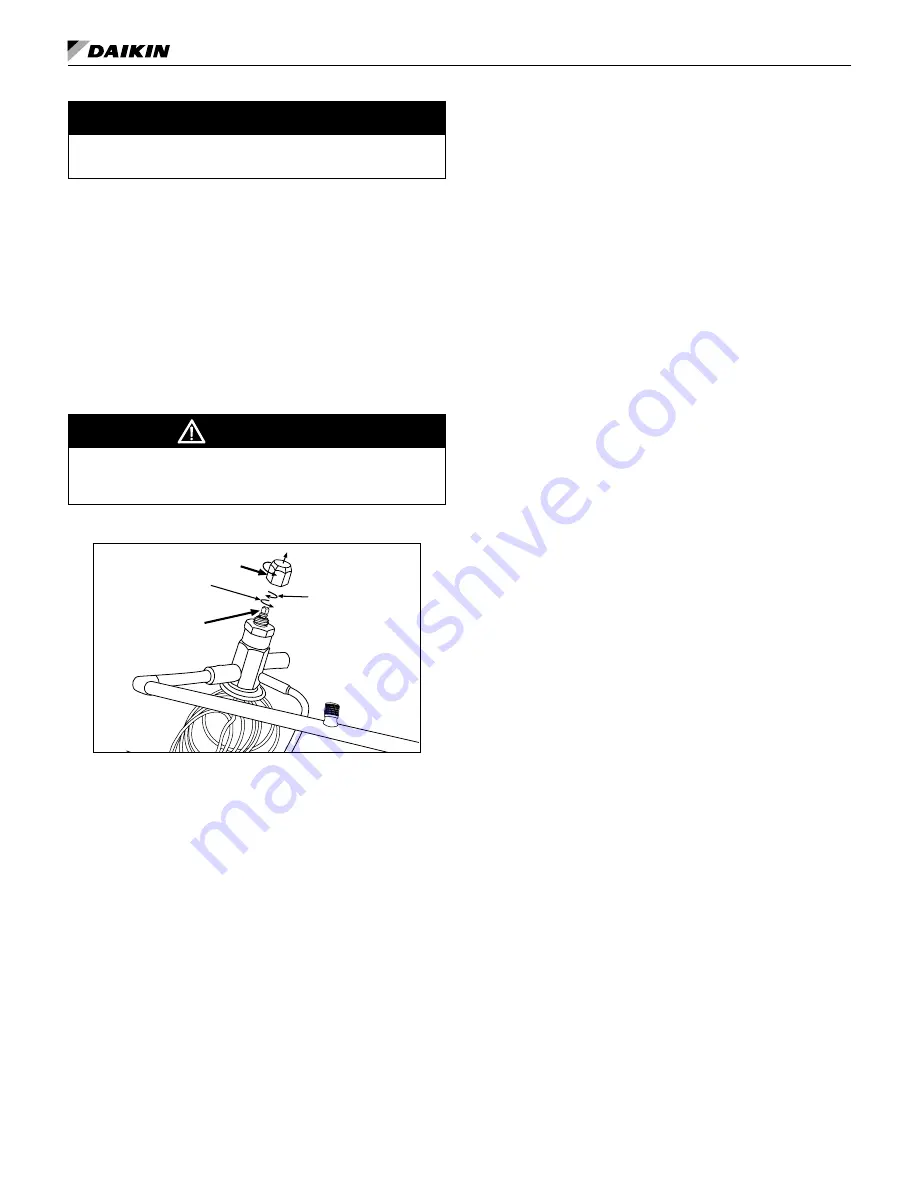

Superheat Adjustment

1 .

Remove the seal cap from thermal expansion valve

(see

).

2 .

Turn the adjustment screw clockwise to increase

superheat and counterclockwise to decrease

changes the superheat approximately 3-4°F,

regardless of the refrigerant type. As much as 30

minutes may be required for the system to stabilize

after the adjustment is made.

3 .

Replace and hand-tighten seal cap.

CAUTION

Do not force adjustment stem of TXV. When adjusting superheat

setting, there are a maximum of 10 turns on the stem. Turning

adjustment stem after reaching stop will damage valve.

Figure 99: Superheat Adjustment of TXV

Superheat

Adjustment Screw

Counterclockwise To

Decrease Superheat

Clockwise To Increase

Superheat

Remove Seal Cap

Making Control Connections

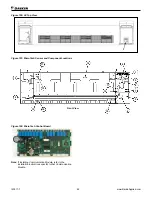

MicroTech Unit Mounted DDC

Control Components – Models

AVS, AVV, and AVR

Note:

1

MicroTech Unit Ventilator Controller (UVC):

(Located

Beneath the Local User Interface Panel). Factory

mounted and run tested, microprocessor-based

DDC control device capable of complete Standalone

unit control, Client/Server control or incorporated

into a building-wide network using an optional plug-

in communication module. The UVC contains a

microprocessor that is preprogrammed with the

application code required to operate the unit. The UVC

supports up to 16 analog inputs, 8 binary inputs, 4

analog outputs, 2 PWM outputs, and 14 binary outputs.

The UVC EXP I/O board supports up to 4 additional

analog inputs and 8 additional binary outputs. Client/

Server units have the controller factory configured

and installed for a local peer-to-peer network between

these units (network wiring between these units needs

to be field installed). Optional network communication

is provided via plug-in communication modules that

connect directly to the UVC.

2

Communication Module (optional):

Plug-in network

communication module that is attached to the UVC

via a 8-pin header and 4 locking standoffs. Available

communication modules:

•

Building Automation and Control Network

(BACnet®) Client Server/Token Passing

(MS/TP)

– Allows the UVC to inter-operate

with systems that use the BACnet (MS/TP)

protocol with a conformance level of 3. Meets

the requirements of ANSI/ASHRAE 135-2008

standard for BACnet systems

•

l

on

W

orks

® compliant Space Comfort

Controller (SCC)

– Supports the

L

on

W

orks

SCC

profile number 8500_10

3

Local User Interface (LUI) (optional):

) The LUI provides a unit mounted

interface which indicates the current unit operating state

and can be used to adjust the unit ventilator operating

parameters (operating mode, temperature set points,

fan speed and occupancy mode). The LUI features a 4

x 20 OLED digit display, 4 keys, and 2 individual LED

indicators. In addition to the operating mode states

and fan functions, the touch pad will digitally display:

•

The room set point temperature

•

The current room temperature

•

Any fault code for quick diagnostics at the unit

4

External Signal Connection Plugs:

Three (3)

multi-pin plugs are factory provided and pre-wired

with short wire whips that are capped (they must

remain capped if not used). Provided for field

wiring of:

•

Remote Wall Mounted Temperature Sensor

(optional accessory)

•

External Input Signals (by others)

–

Unoccupied, remote shutdown, ventilation lockout,

dew point/humidity (night time operation), or

exhaust interlock signals

•

External Output Options (by others)

– Fault

indication signal, exhaust fan on/off or auxiliary

heat signal

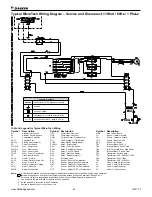

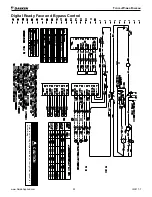

5

Electric Connection Box:

Contains the motor speed

transformer. Refer to the unit wiring diagram for

specifics.