IM 817-4

Page 53 of 60

Draftstop is made up of three separate sections as listed below:

1.

Upper channel or backplate

2.

Mounting components

3.

Enclosures and trims

Items 1, and 2 are materials which will be required to start the installation.

Item 3 is the completion material and should be stored in a safe area

until needed.

The following step-by-step procedures should be adhered to:

1.

Check the area in which the equipment is to be installed and clear

away the debris.

2. Review the engineered floor plans or the approved equipment

room schedule.

3.

Place the proper amount of equipment in each area in accordance

with plans or schedule.

4.

Proceed to install the equipment as outlined on the following pages.

Refer to the installation instructions included with the Draftstop

system for more detailed information.

Upper Channel or Backplate Assembly

1. Establish a level chalk line on the wall at a height specified for the

top of the enclosure. Select mounting hardware which is suitable

for the type of wall construction used and mount the upper channel

or backplate flush with the chalk line. When mounting, use the

prepunched holes and push the hardware through the sponge

gasket.

Note:

a.

The upper channel is provided with continuous 5/16"

diameter holes on 2" centers for mounting.

b.

Where used, the backplate assembly consists of a full backplate

welded to the back of the upper channel. Fasten the backplate at

the bottom as well as at the top.

2.

Wall-to-Wall Application: Starting at the left side, run the upper

channel or backplate along the wall. Note that the upper channel or

backplate is installed behind the wall trim as well as the enclosure,

because both the enclosure and wall trim rest in the top groove of

the upper channel.

3.

Wall-to-End Application: Run the upper channel or backplate from

the wall to a point where the enclosure will end. See Draftstop

installation instructions for details of end cap installation.

4.

End-to-End Application: Run the upper channel or backplate the

same length as the enclosure. See Draftstop installation instructions

for details or end cap installation.

5.

For inside corners, run the upper channel or backplate into the

corner, butting the pieces together. If desired, pieces may be

stopped short of the corner a maximum of one inch. Refer to the

Draftstop installation instructions for details of the corner trim

installation.

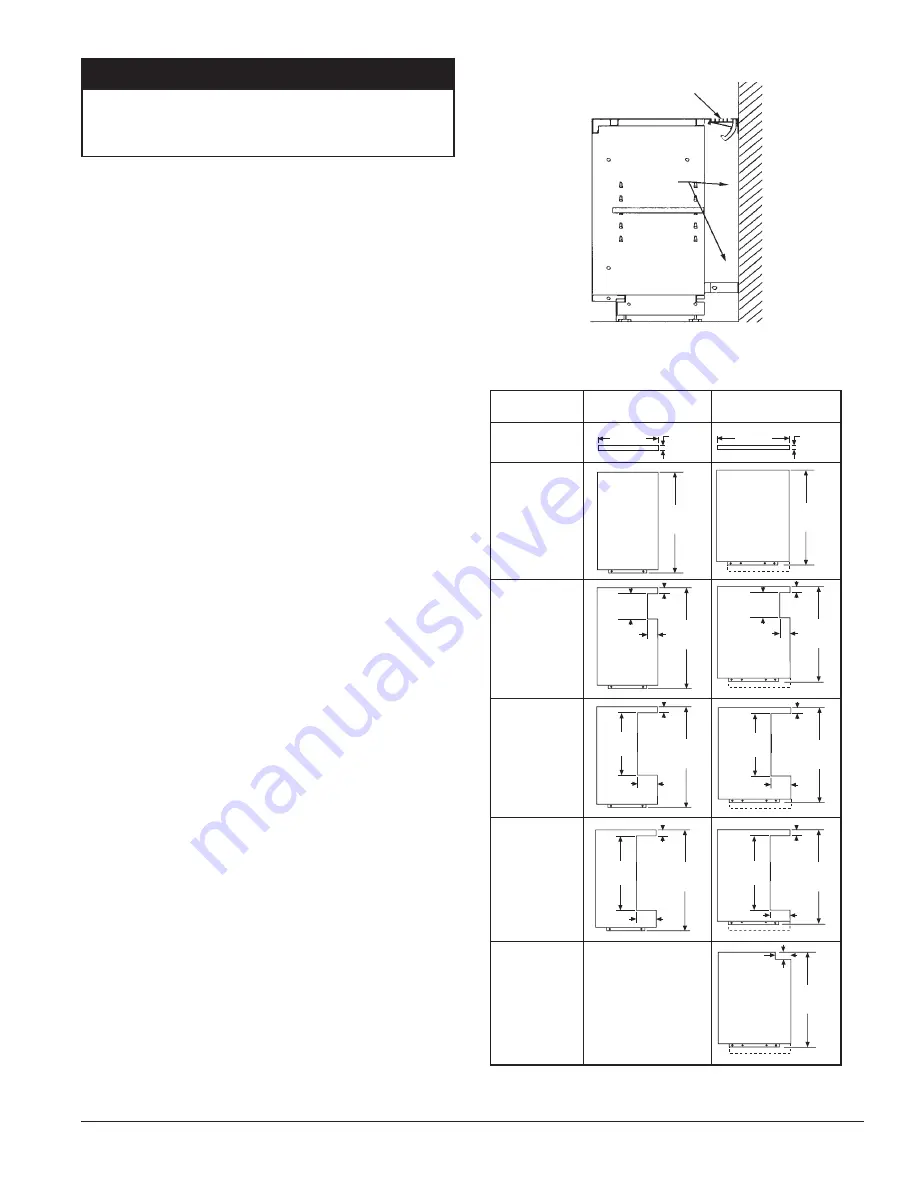

The Draftstop enclosure and unit ventilator end panel should be

matched, to ensure proper airflow. Tables 31-34 show the various end

panels available, follow installation instructions included with the

end panels.

NOTICE

The following information is a general outline for installing the

Draftstop system. Refer to the specific installation instructions

provided with the Draftstop system equipment.

Draftstop Bar Grille and Adjustable Damper

Piping

Area

Figure 128 - Typical DraftStop Enclosure

All Dimensions

in Inches

16

5

/

8

" (422mm) Deep

End Panels

21

7

/

8

" (556mm) Deep

End Panels

Top View

End View

With 4" x 18"

(102mm x

457mm)

Cut-out

End View

With 2

1

/

2

" x 7"

(64mm x

178mm)

Cut-out

End View

With No

Cut-out

End View

With 4" x 22"

(102mm x

559mm)

Cut-out

End View

With 2" x 5

1

/

4

"

(51mm x

133mm)

Step Down

Table 31 - 1" (25mm) End Panel Dimensions – Floor Unit Ventilators

27

7

/

8

"

(708mm)

27

7

/

8

"

(708mm)

7"

(178mm)

2

1

/

2

"

(64mm)

1"

(25mm)

27

7

/

8

"

(708mm)

18"

(457mm)

4"

(102mm)

1"

(25mm)

27

7

/

8

"

(708mm)

22"

(559mm)

4"

(102mm)

1"

(25mm)

16

5

/

8

"

(422mm)

1"

(25mm)

27

7

/

8

"

(708mm)

27

7

/

8

"

(708mm)

7"

(178mm)

2

1

/

2

"

(64mm)

1"

(25mm)

27

7

/

8

"

(708mm)

18"

(457mm)

4"

(102mm)

1"

(25mm)

27

7

/

8

"

(708mm)

22"

(559mm)

4"

(102mm)

1"

(25mm)

21

7

/

8

"

(556mm)

1"

(25mm)

27

7

/

8

"

(708mm)

2"

(51mm)

5

1

/

4

"

(133mm)