Main Functions

Si12-714

56

Function and Control

1. Main Functions

Note:

See the list of functions for the functions applicable to different models.

1.1

Frequency Principle

Main Control

Parameters

The compressor is frequency-controlled during normal operation. The target frequency is set by

the following 2 parameters coming from the operating indoor unit:

The load condition of the operating indoor unit

The difference between the room temperature and the set temperature

Additional

Control

Parameters

The target frequency is adapted by additional parameters in the following cases:

Frequency restrictions

Initial settings

Forced cooling / heating operation

Inverter Principle

To regulate the capacity, a frequency control is needed. The inverter makes it possible to vary

the rotation speed of the compressor. The following table explains the conversion principle:

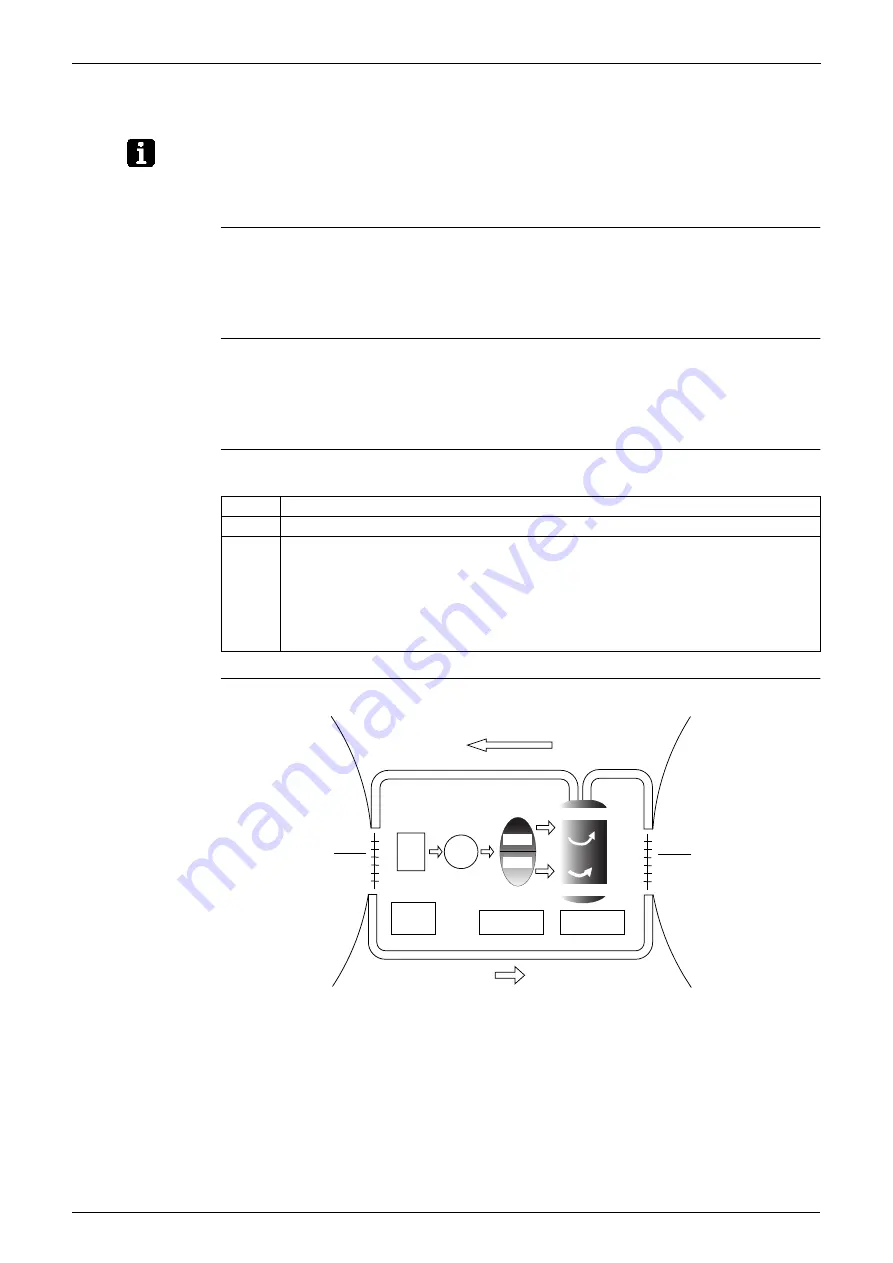

Drawing of

Inverter

The following drawing shows a schematic view of the inverter principle:

Phase

Description

1

The supplied AC power source is converted into the DC power source for the present.

2

The DC power source is reconverted into the three phase AC power source with variable

frequency.

When the frequency increases, the rotation speed of the compressor increases resulting

in an increased refrigerant circulation. This leads to a higher amount of the heat

exchange per unit.

When the frequency decreases, the rotation speed of the compressor decreases

resulting in a decreased refrigerant circulation. This leads to a lower amount of the heat

exchange per unit.

50 Hz

60 Hz

Refrigerant circulation rate (high)

Amount of heat

exchanged air (large)

Amount of heat

exchanged air (small)

AC

po

w

er

freq=

constant

DC

po

w

er

Amount of heat

exchanged air (large)

Amount of heat

exchanged air (small)

high f

low f

freq=variable

capacity=

variable

Refrigerant circulation rate (low)

high speed

low speed

(R2812)