IM 1038 • VAV ACTUATOR ROOM SENSOR 4

www .DaikinApplied .com

I

nstallatIon

I

nstallatIon

The following section describes how to field install a new

BACnet VAV Actuator Room Sensor . Expected Install Time:

20 minutes

CAUTION

Electrostatic discharge hazard. Can cause equipment

damage.

This equipment contains sensitive electronic components that

may be damaged by electrostatic discharge from your hands .

Before you handle a communications module, you need to

touch a grounded object, such as the metal enclosure, in

order to discharge the electrostatic potential in your body .

Required Tools and Materials

• Phillips sizes 1 and 2 screwdrivers

•

Small and medium flat-blade screwdrivers

• 1/16-inch hex key

• Medium-duty electric drill

• 3/16-inch (4 .8 mm) drill bit

• One-inch (25 mm) hole saw

• Small level

• Tape measure

• Marker or pencil

If using non-terminated or damaged cables, you also need:

• Room sensor connector tool (RJ-11 crimping tool)

• Room sensor connector kit (P/N 2508046)

Installing a new BACnet VAV Actuator

Room Sensor

Mounting Information

Always mount the room sensor vertically, on a flat wall.

Locate the room sensor:

•

According to design specifications and local regulations.

• Where the air circulates around it freely (not in recessed

areas or behind doors) .

• Allowing a minimum of 4 inches (10 cm) free space above

and below for proper airflow, the hex bit or passkey tool,

and the computer communication cable .

• Away from drafts caused by doors, windows, outside

walls, air registers, pipes, return air plenums, etc .

•

Away from heat sources such as strong lights, fireplaces,

direct sunlight, etc .

• On an inside wall (preferably), about 5 feet (1 .5 m)

above the finished floor or per code (ANSI, ADA, or local

regulation) .

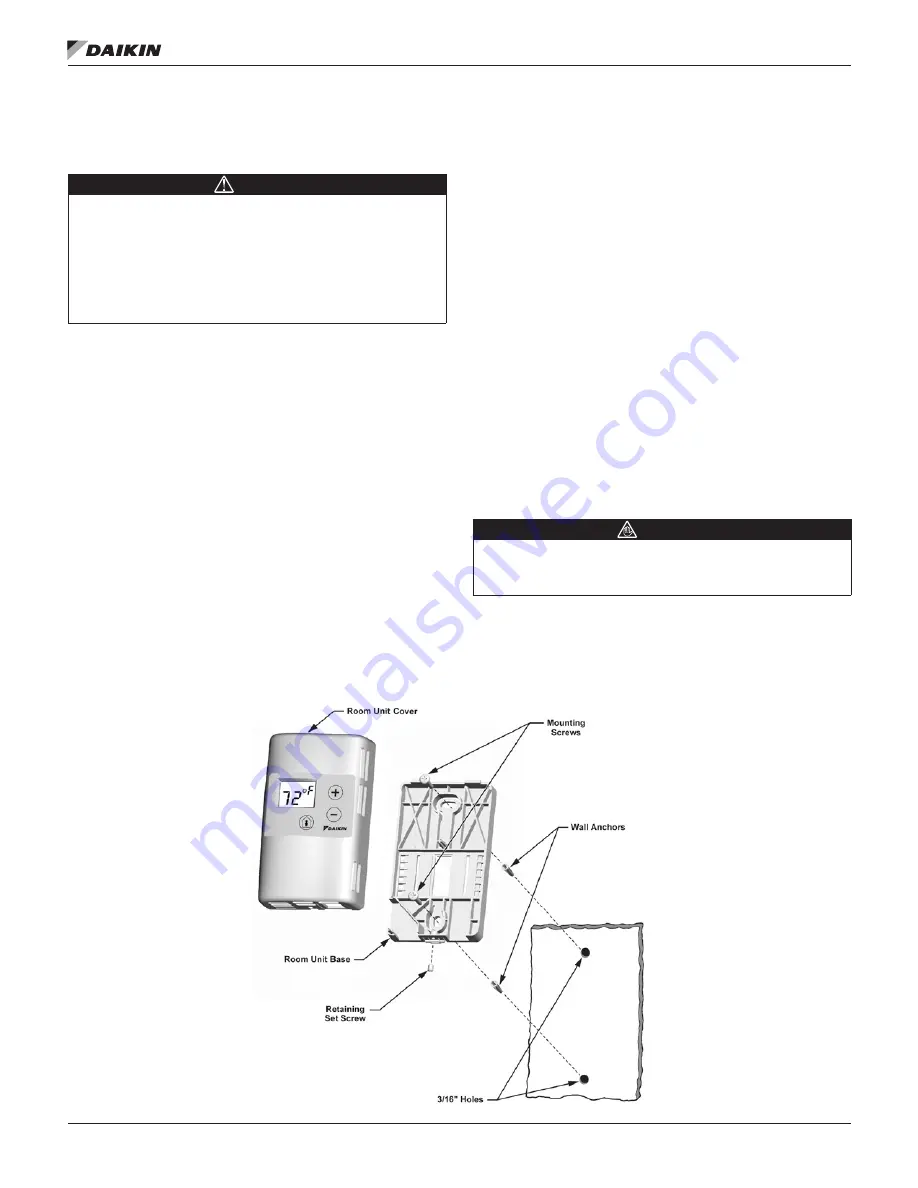

Drywall Mounting (No Rough-in), Typical

WARNING

For retrofits: Before cutting the cable, make sure it is

disconnected from the Temperature Room Sensor port on the

controller cable end .

1 . Mark the center (cable) hole and the mounting hole

locations, using the room sensor base plate as a

template . See Figure 2 .

Figure 2: Drywall Mounting (No Rough-in), Typical