5 Configuration

Installation manual

14

C08AA

Daikin hybrid for multi heat pump – heat pump module

4P471756-1C – 2017.10

01

02

06

0a

0e

00

03

07

0b

0f

00

00

04

08

0c

00

01

05

09

0d

15

Overview settings

Confirm

Adjust

Scroll

3

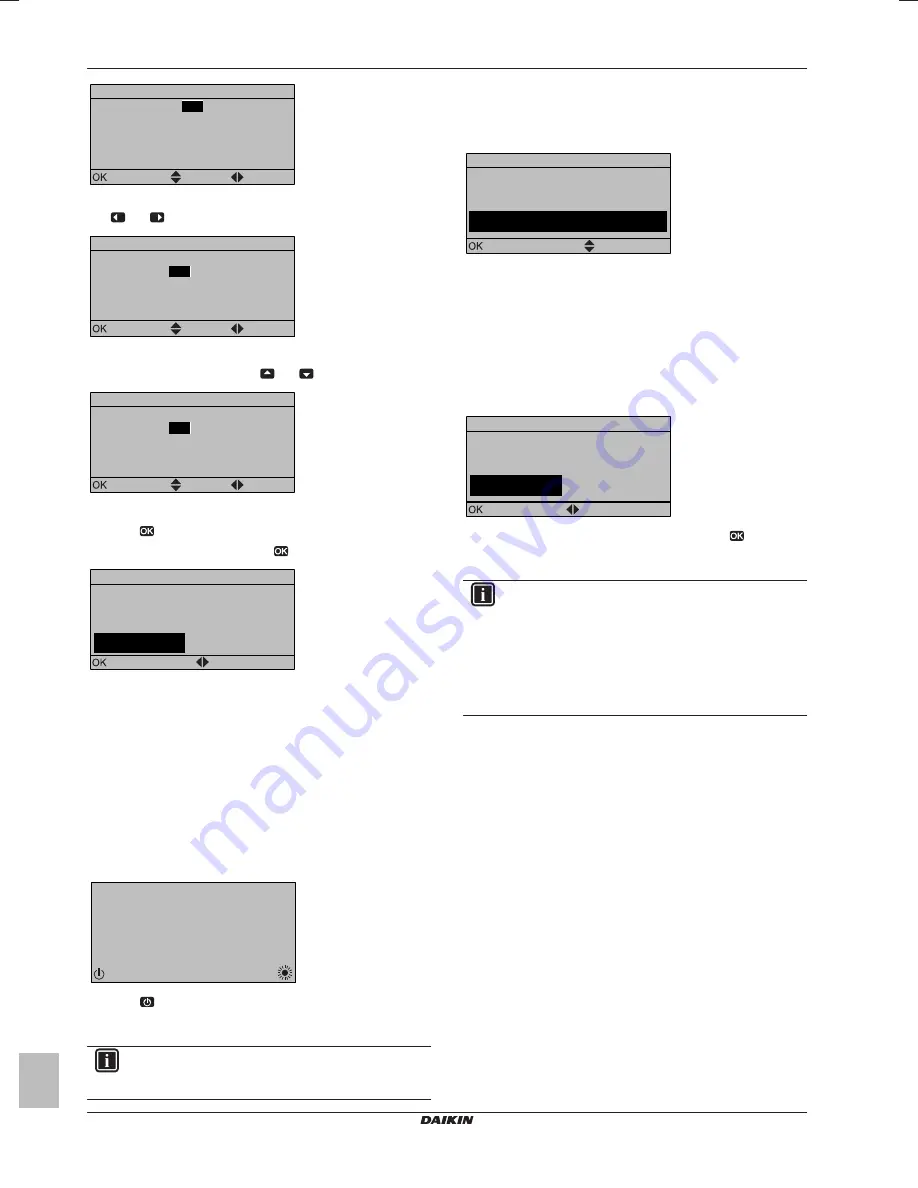

Go to the corresponding second part of the setting by using the

and

button.

01

02

06

0a

0e

00

03

07

0b

0f

00

00

04

08

0c

00

01

05

09

0d

15

Overview settings

Confirm

Adjust

Scroll

Result:

The value to be modified is now highlighted.

4

Modify the value by using the

and

button.

01

02

06

0a

0e

00

03

07

0b

0f

00

00

04

08

0c

00

01

05

09

0d

20

Overview settings

Confirm

Adjust

Scroll

5

Repeat previous steps if you have to modify other settings.

6

Push

to confirm the modification of the parameter.

7

At installer settings menu, press

to confirm the settings.

Installer settings

The system will restart.

Confirm

Adjust

Cancel

OK

Result:

The system will restart.

To copy the system settings from the first to the

second user interface

If a second user interface is connected, the installer must first

proceed below instructions for the proper configuration of the 2 user

interfaces.

This procedure offers you also the possibility to copy the language

set from one user interface to the other one: e.g. from EKRUCBL2 to

EKRUCBL1.

1

When power is turned on for the first time, both user interfaces

display:

15:10

Tue

U5:Auto address

Push 4 sec. to continue

2

Push

for 4 seconds on the user interface on which you want

to proceed to the quick wizard. This user interface is now the

main user interface.

INFORMATION

During the quick wizard, the second user interface displays

Busy and will NOT be possible to operate.

3

The quick wizard will guide you.

4

For proper operation of the system, the local data on the two

user interfaces must be the same. If this is NOT the case, both

user interfaces will display:

Synchronization

Data difference detected.

Please select action:

Send data

Confirm

Adjust

5

Select the required action:

▪ Send data: the user interface you are operating contains the

correct data and the data on the other user interface will be

overwritten.

▪ Receive data: the user interface you are operating does

NOT contain the correct data and the data on the other user

interface will be used to overwrite.

6

The user interface requests confirmation if you are sure to

proceed.

Start copy

Are you sure you want to

start the copy operation?

Cancel

OK

Confirm

Adjust

7

Confirm the selection on the screen by pushing

and all data

(languages, schedules etc.) will be synchronised from the

selected source user interface to the other one.

INFORMATION

▪ During the copying, both controllers will NOT allow

operation.

▪ The copy operation can take up until 90 minutes.

▪ It is recommended to change installer settings, or the

configuration of the unit, on the main user interface. If

not, it can take up to 5 minutes before these changes

are visible in the menu structure.

8

Your system is now set to be operated by the 2 user interfaces.

To copy the language set from the first to the

second user interface

See

"To copy the system settings from the first to the second user

interface" on page 14

.

Quick wizard: Set the system layout after first

power ON

After first power ON of the system, you are guided on the user

interface to do initial settings:

▪ language,

▪ date,

▪ time,

▪ system layout.

By confirming the system layout, you can proceed with the

installation and commissioning of the system.

1

At power ON, the quick wizard starts as long as the system

layout was NOT confirmed yet, by setting the language.