8 Technical data

Installation manual

30

C08AA

Daikin hybrid for multi heat pump – heat pump module

4P471756-1C – 2017.10

8.5

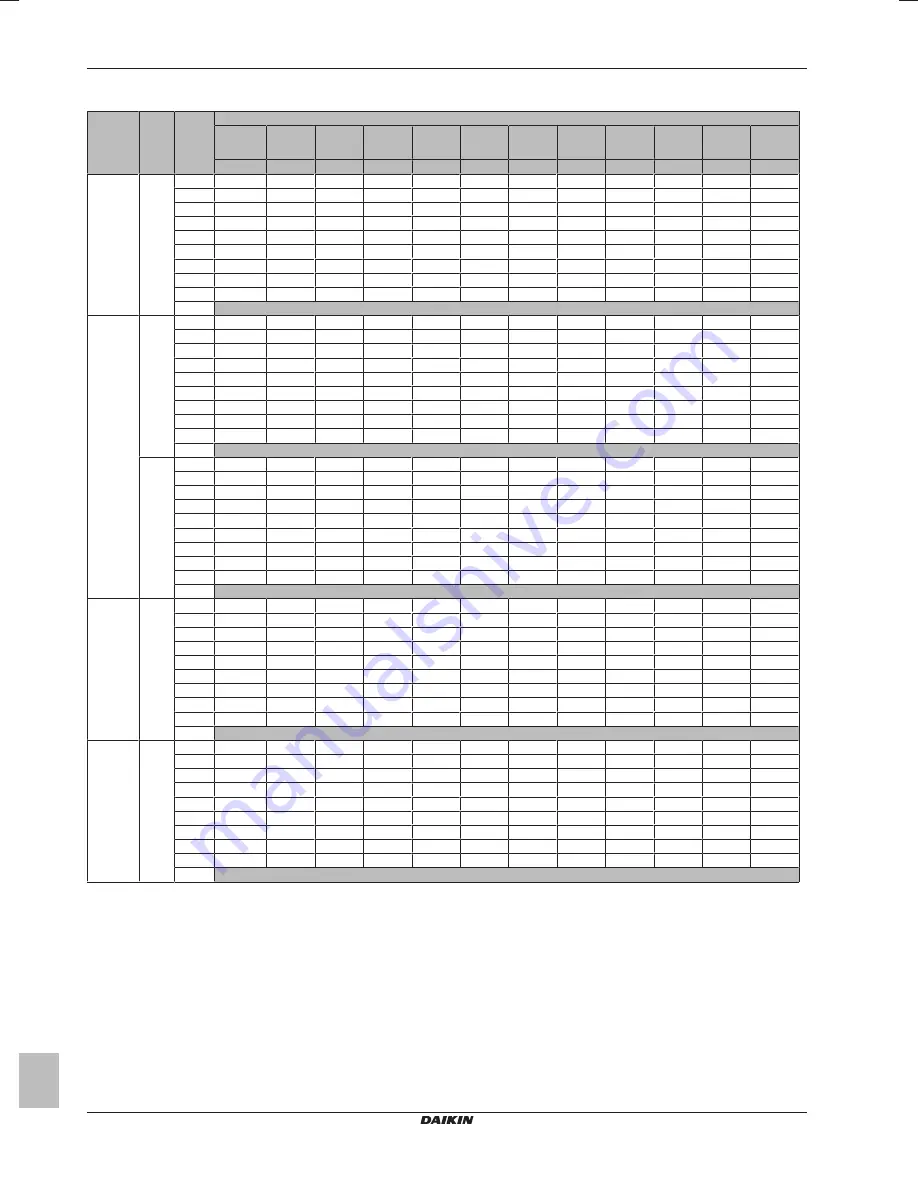

Table 3 – Minimum venting opening area for natural ventilation: indoor unit

m

c

(kg)

dm=m

c

–

m

max

(kg)

Minimum venting opening area (cm

2

)

H=500 mm,

600 mm,

700 mm

H=800 mm

H=900 mm

H=1000 mm H=1100 mm H=1200 mm H=1300 mm H=1400 mm H=1500 mm H=1600 mm H=1700 mm H=1800 mm

h=600 mm

h=700 mm

h=800 mm

h=900 mm

h=1000 mm h=1100 mm h=1200 mm h=1300 mm h=1400 mm h=1500 mm h=1600 mm h=1700 mm

3MXM52

1.8

1.62

659

610

571

538

511

487

466

448

432

417

404

392

1.44

586

542

507

478

454

433

414

398

384

371

359

348

1.26

513

475

444

419

397

379

363

348

336

324

314

305

1.08

440

407

381

359

341

325

311

299

288

278

269

261

0.90

378

339

317

299

284

271

259

249

240

232

225

218

0.72

331

284

254

239

227

217

207

199

192

186

180

174

0.54

268

230

201

180

171

163

156

150

144

139

135

131

0.36

191

164

144

128

115

109

104

100

96

93

90

87

0.18

102

87

76

68

61

56

52

50

48

47

45

44

0.00

4MXM68

2

1.80

732

678

634

598

567

541

518

498

480

463

449

435

1.60

651

603

564

532

504

481

460

442

426

412

399

387

1.40

570

527

493

465

441

421

403

387

373

360

349

339

1.20

488

452

423

399

378

361

345

332

320

309

299

290

1.00

442

379

353

332

315

301

288

277

267

258

249

242

0.80

388

332

291

266

252

241

230

221

213

206

200

194

0.60

314

269

236

210

189

181

173

166

160

155

150

145

0.40

224

192

168

150

135

122

115

111

107

103

100

97

0.20

119

102

89

80

72

65

60

56

54

52

50

49

0.00

2.2

1.98

805

746

698

658

624

595

570

547

527

510

493

479

1.76

716

663

620

585

555

529

506

487

469

453

439

426

1.54

627

580

543

512

485

463

443

426

410

396

384

372

1.32

548

497

465

439

416

397

380

365

352

340

329

319

1.10

510

437

388

366

347

331

317

304

293

283

274

266

0.88

447

383

336

298

278

265

253

244

235

227

220

213

0.66

362

311

272

242

218

199

190

183

176

170

165

160

0.44

258

222

194

172

155

141

129

122

118

114

110

107

0.22

137

118

103

92

83

75

69

64

59

57

55

54

0.00

5MXM90

2.4

2.16

879

813

761

717

681

649

621

597

575

556

538

522

1.92

781

723

676

638

605

577

552

531

511

494

478

464

1.68

683

633

592

558

530

505

483

464

448

432

419

406

1.44

624

542

507

478

454

433

414

398

384

371

359

348

1.20

581

498

436

399

378

361

345

332

320

309

299

290

0.96

510

437

382

340

306

289

276

266

256

247

239

232

0.72

413

354

310

275

248

225

207

199

192

186

180

174

0.48

294

252

221

196

177

161

147

136

128

124

120

116

0.24

156

134

117

104

94

86

78

72

67

63

60

58

0.00

5MXM90

2.6

2.34

952

881

824

777

737

703

673

647

623

602

583

566

2.08

846

783

733

691

655

625

598

575

554

535

518

503

1.82

740

685

641

605

574

547

524

503

485

468

454

440

1.56

703

603

550

518

492

469

449

431

416

402

389

377

1.30

655

562

492

437

410

391

374

360

346

335

324

314

1.04

574

492

431

383

345

314

299

288

277

268

259

252

0.78

465

399

349

310

279

254

233

216

208

201

195

189

0.52

332

285

249

221

199

181

166

153

143

134

130

126

0.26

176

151

132

118

106

96

88

82

76

71

66

63

0.00