cm-clic-cf-eng

www.clima-flex.com

12

COMMUNICATION PROTOCOL

The pCO has 4 independent communication ports configured as

follows:

• pLAN: Communicates with the pGD touch terminal using the Modbus

RTU protocol “Son”.

• Fieldbus 1: Communicates with the Expansion Modules (located in the

“Child” units) using the Modbus “Mother” protocol.

• BMS1: Communicates with a supervisory system using the BACnet*

protocol (License required).

• BMS2: Communicates with an external supervisory system such as

PlanWatch Pro using the Modbus RTU “Child” protocol.

Note:

The BMS1 port requires a communication card (pCOnet

to BACnet MS/TP or pCOweb for BACnet IP).

The

programming of the logic packet in the switching

protocol is also required.

An FLG-Modbus can also be connected to connect a BACnet

MS/TP.

ALARMS

The alarms that may occur, depending on the initial configuration

are:

• Sensor Failure Alarms: If a sensor is detected as disconnected or

broken, the algorithm being used will be disabled. If it is the head

injection sensor that was detected, the units will work in “Independent”

mode automatically.

• Phase Fault Alarm: Activated by a digital input. Motor protection is a

high priority alarm and stops all machine functions. It is reset manually.

• No Flow” Alarm: This alarm is a high priority alarm and stops all

machine functions. It is manually reset.

• Freeze Alarm: If the sensor temperature is below the programmed

threshold, this alarm will be activated. This condition stops all

functions of the equipment in question. This alarm automatically resets

once the temperature exceeds the reset value and will keep the unit in

reset mode (No power for operation for the programmed time.

• Water Freeze Alarm: Same case as the freeze alarm, but in this alarm,

the injection sensor reading is considered.

• High Pressure Alarm: It is triggered by a Digital input. This alarm is

a high priority event and stops the compressor operation, however it

does not disable the pump. It is a manual reset alarm. If it is an air-

cooled unit, a command will be sent to start the condenser fan. To

restart, keep the unit on high output, the compressor will not start until

the programmed time has elapsed.

• Low Pressure Alarm: This is activated by a digital input. This alarm

stops the compressor of the unit in question. It resets automatically,

however it keeps the unit in a low performance mode.

• Disconnect Alarm: If the system contains any “Son” units and any of

these units are disconnected, this alarm will be activated.

• High Condenser Temperature Alarm: This alarm is only available when

the unit is air cooled. The alarm is activated when the condenser

temperature reading exceeds the limit. No control action is taken.

• Condenser Flow Alarm: This alarm functions like the main Flow alarm;

it is activated only when the cooling system is water cooled.

• Lack of Refrigerant Alarm: This alarm is activated when a start

command is sent due to cooling demand, and the injection temperature

sensor detects a change in temperature for a period of time. This alarm

does not take Control actions and can be deactivated by the user.

USER INTERFACE

Navigation Bar

The Navigation bar is found on every

screen of the system. It appears

and disappears automatically by

pressing the tab at the bottom, as

shown in Fig. 11.

Figure 11. On-screen navigation

bar

When the tab is pressed the navigation menu will be displayed, as

in Fig. 12.

Figure 12. Example of navigation bar on the main screen

The navigation menu changes the access icons depending on

the context where the user is in the system. Potential navigation

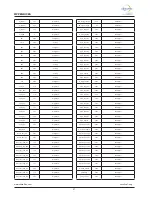

buttons are shown below.

Control