90

SERVICING

4.4

Once the defrost cycle is terminated, the heat pump

commands the air handler/modular blower to end defrost

operation.

4.5

The system returns to heat pump heating operation that was

in effect prior to the defrost cycle.

5.0 Emergency Heat Operation

5.1

The CTK0* thermostat sends a request for emergency heat

to the air handler/modular blower.

5.2

The air handler control energizes the ECM blower motor

at the emergency heat speed. The electric heat sequencer

outputs are also energized, thus energizing the electric

heaters.

5.3

The system operates at emergency heat.

5.4

Once the thermostat demand is satisfied, the CTK0*

thermostat commands the air handler/modular blower

to end emergency heat operation. The air handler control

de-energizes the electric heat sequencer outputs. The ECM

blower motor remains energized until any blower OFF delay

timing has expired. energizes the variable speed ECM motor

at fan demand provided by the thermostat. The fan demand

provided by the thermostat will be 30%, 50%,or 70% of the

air handler’s maximum airflow capability. The continuous

fan demand is set from the thermostat as low, medium, or

high.

S-60 ELECTRIC HEATER (OPTIONAL ITEM)

Optional electric heaters may be added, in the quantities shown

in the specifications section, to provide electric resistance

heating. Under no condition shall more heaters than the quantity

shown be installed.

The low voltage circuit in the air handler is factory wired and

terminates at the location provided for the electric heater(s). A

minimum of field wiring is required to complete the installation.

Other components such as a Heating/Cooling Thermostat and

Outdoor Thermostats are available to complete the installation.

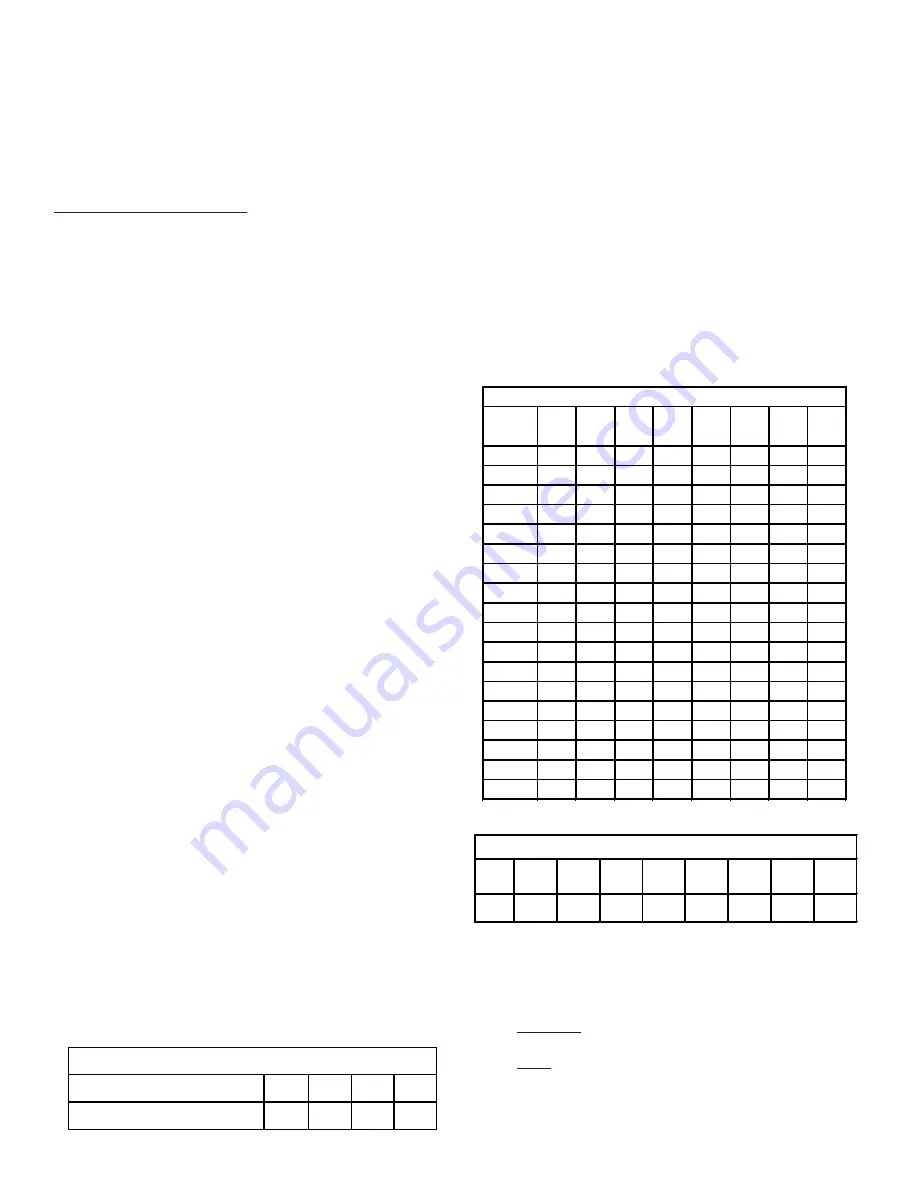

The system CFM can be determined by measuring the static

pressure external to the unit. The installation manual supplied

with the blower coil, or the blower performance table in the

service manual, shows the CFM for the static measured.

Alternately, the system CFM can be determined by operating

the electric heaters and indoor blower WITHOUT having the

compressor in operation. Measure the temperature rise as close

to the blower inlet and outlet as possible.

If other than a 240V power supply is used, refer to the

BTUH

CAPACITY CORRECTION FACTOR

chart below.

BTUH CAPACITY CORRECTION FACTOR

SUPPLY VOLTAGE

250

230

220

208

MULTIPLICATION FACTOR 1.08

.92

.84

.75

EXAMPLE:

Five (5) heaters provide 24.0 KW at the rated

240V. Our actual measured voltage is 220V, and our measured

temperature rise is 42°F. Find the actual CFM:

Answer:

24.0KW, 42°F Rise, 240 V = 1800 CFM from the

TEMPERATURE RISE

chart on the right.

Heating output at 220 V = 24.0KW x 3.413 x .84 = 68.8 MBH.

Actual CFM = 1800 x .84 Corr. Factor = 1400 CFM.

NOTE:

The temperature rise table is for sea level installations.

The temperature rise at a particular KW and CFM will be greater

at high altitudes, while the external static pressure at a particular

CFM will be less.

CFM 3.0

kW

4.8

kW

7.2

kW

9.6

kW

14.4

kW

19.2

kW

24.0

kW

28.8

kW

600

16

25

38

51

-

-

-

-

700

14

22

33

43

-

-

-

-

800

12

19

29

38

57

-

-

-

900

11

17

26

34

51

-

-

-

1000

10

15

23

30

46

-

-

-

1100

9

14

21

27

41

55

-

-

1200

8

13

19

25

38

50

-

-

1300

7

12

18

23

35

46

-

-

1400

7

11

16

22

32

43

54

65

1500

6

10

15

20

30

40

50

60

1600

6

9

14

19

28

38

47

57

1700

6

9

14

18

27

36

44

53

1800

5

8

13

17

25

34

42

50

1900

5

8

12

16

24

32

40

48

2000

5

8

12

15

23

30

38

45

2100

5

7

11

14

22

29

36

43

2200

4

7

11

14

21

27

34

41

2300

4

7

10

13

20

26

33

39

TEMPERATURE RISE (°F) @ 240V

HTR

KW

3.0

KW

4.7

KW

6.0

KW

7.0

KW

9.5

KW

14.2

KW

19.5

KW

21.0

KW

BTUH 10200 16200 20400 23800 32400 48600 66500 71600

ELECTRIC HEATER CAPACITY BTUH

FORMULAS:

Heating Output = KW x 3413 x Corr. Factor

Actual CFM = CFM (from table) x Corr. Factor

BTUH = KW x 3413

BTUH = CFM x 1.08 x Temperature Rise (T)

CFM = KW x 3413

1.08 x T

T = BTUH

CFM x 1.08