SiBE12-908

Troubleshooting

Service Diagnosis

131

2.21

Discharge Pipe Temperature Control

Remote

Controller Display

F3

Outdoor Unit LED

Display

A

5

5

5

( - )

Method of

Malfunction

Detection

Discharge pipe temperature control (stop, frequency attenuation, etc.) is executed based on the

temperature detected by the discharge pipe thermistor.

Malfunction

Decision

Conditions

If the temperature being detected by the discharge pipe thermistor rises, the compressor will

stop. The temperature at which the compressor halts varies according to the frequency.

(1) 110°C when the frequency is above 30Hz on ascending or above 25Hz on descending.

(2) 108°C when the frequency is below 30Hz on ascending or below 25Hz on descending.

The error is cleared when the temperature has dropped below 95°C.

If the compressor stops 6 times successively due to abnormal discharge pipe temperature,

the system will be shut down.

The error counter will reset itself if this or any other error does not occur during the following

60-minute compressor running time (total time).

Supposed

Causes

Insufficient gas

Faulty operation of four way valve

Defective discharge pipe thermistor

(Defective heat exchanger thermistor or outdoor air thermistor)

Defective outdoor unit PCB

Water mixed in the field piping

Defective electronic expansion valve

Defective stop valve

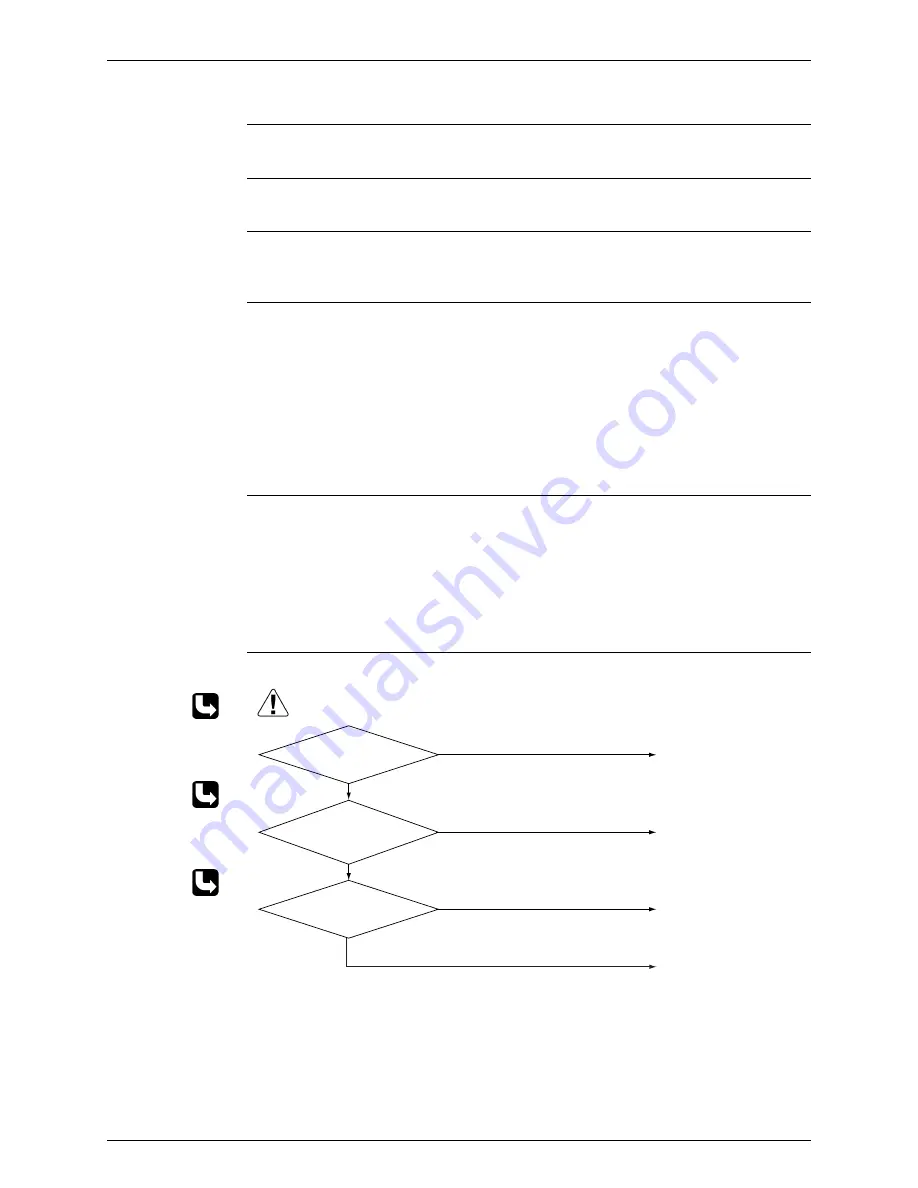

Troubleshooting

Check No.02

Refer to P.162

Check No.12

Refer to P.165

Check No.17

Refer to P.169

(R9442)

Caution

Be sure to turn off power switch before connect or disconnect connector,

or parts damage may be occurred.

Malfunctioning

z

Discharge pipe thermistor

z

Outdoor unit heat exchanger thermistor

z

Outdoor temperature thermistor

z

Refrigerant shortage

z

Four way valve malfunctioning

z

Water mixed

z

Stop valve defective

Functioning

Functioning

Functioning

Malfunctioning

Malfunctioning

Replace the

defective

thermistor.

Replace the valve itself or

the coil.

Refer to the refrigerant line

check procedure.

Replace the outdoor unit

PCB.

Check No. 02

Check the

thermistors.

Check No. 17

Check the electronic

expansion valve.

Check No. 12

Check the

refrigerant line.