Si18-525B

Service Check Function

Troubleshooting

325

2.6

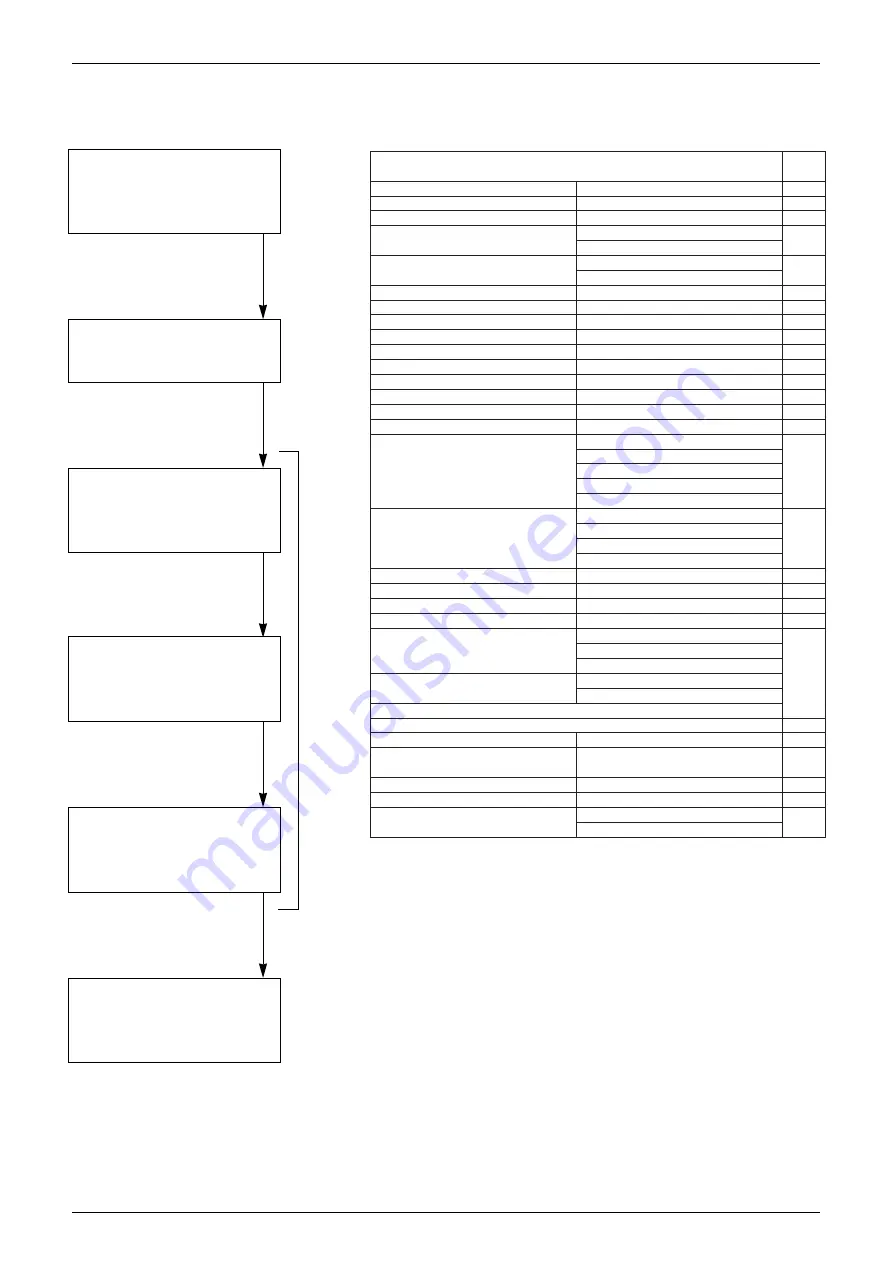

Malfunction Code Indication by Outdoor Unit PCB

<Selection of setting item>

<Monitor mode>

<Confirmation of malfunction 1>

To enter the monitor mode, push the

MODE button (BS1) when in

“Setting mode 1”.

Push the SET button (BS2) and set

the LED display to a setting item.

Push the RETURN button (BS3)

once to display "First digit" of

malfunction code.

<Confirmation of malfunction 2>

Push the SET button (BS2) once to

display "Second digit" of malfunction

code.

Push the RETURN button (BS3) and

switches to the initial status of

“Monitor mode”.

∗

Push the MODE button (BS1) and

returns to “Setting mode 1”.

Contents of malfunction

Malfunction

code

<Confirmation of malfunction 3>

Push the SET button (BS2) once to

display "master or slave1 or slave2"

and "malfunction location".

Detail

description

on the

right.

(V3167)

HPS activated

Abnormal Pe

Detection of INV compressor lock

Instantaneous over current of DC fan motor

Detection of DC fan motor lock

EV1

EV2

Faulty Ta sensor

Abnormal Td

Faulty Tdi sensor

Faulty Ts sensor

Faulty Tb sensor

Faulty Tsh sensor

Faulty Pc sensor

Faulty Pe sensor

Inverter radiation fin over heated

Inverter instantaneous over current

Electronic thermal switch 1

Electronic thermal switch 2

Out-of-step

Speed down after startup

Lightening detection

Stall prevention (Current increasing)

Stall prevention (Faulty startup)

Abnormal wave form in startup

Out-of-step

Inverter transmission error

Faulty thermistor of inverter fin

Incorrect combination of inverter and fan driver

Gas shortage alarm

Insufficient inverter voltage

Inverter open phase (phase T)

Charging error of capacitor in inverter main circuit

Over voltage

Over current/Over voltage (Hard detection)

I/O transmission error

Indoor unit system malfunction in other system or

other unit of own system

Conflict of refrigerant type in indoor units

Incorrect wiring (Auto address error)

Malfunction of multi level converter, abnormality in

conflict check

Abnormal discharge pressure

Abnormal suction pressure

Compressor lock

Over load, over current,

abnormal lock of outdoor unit fan motor

Malfunction of electronic expansion valve

Faulty sensor of outdoor air temperature

Abnormal discharge pipe temperature

Faulty sensor of discharge pipe temperature

Faulty sensor of suction pipe temperature

Faulty sensor of heat exchanger temperature

Faulty sensor of subcool heat exchanger temperature

Faulty sensor of discharge pressure

Faulty sensor of suction pressure

Inverter radiation fin temperature rise

DC output over current

Electronic thermal switch

Stall prevention (Limit time)

Transmission error between inverter and outdoor unit

Faulty temperature sensor of inverter radiation fin

Incorrect combination of inverter and fan driver

Gas shortage

Abnormal power supply voltage

Abnormal SP-PAM

Abnormal latch circuitry

No implementation of test-run

Transmission error between indoor and outdoor unit

Transmission error of other system

Erroneous on-site setting

Faulty system function

Transmission error in accessory devices, conflict

in wiring and piping, no setting for system

E3

E4

E5

E7

E9

H9

F3

J3

J5

J6

J9

JA

JC

L4

L5

L8

L9

LC

P4

PJ

U0

U2

U3

U4

U9

UA

UH

UF

Summary of Contents for D-Series

Page 1: ...Si18 525B Applied Models Super Multi Plus Cooling only Super Multi Plus Heat Pump D Series ...

Page 33: ...List of Functions Si18 525B 20 List of Functions ...

Page 71: ...Specifications Si18 525B 58 Specifications ...

Page 117: ...Refrigerant Flow for Each Operation Mode Si18 525B 104 Refrigerant Circuit ...

Page 171: ...Indoor Unit SkyAir Models Si18 525B 158 Function ...

Page 207: ...Test Operation and Field Setting for RA Indoor Unit Si18 525B 194 Test Operation ...

Page 336: ...Si18 525B Service Check Function Troubleshooting 323 ...

Page 469: ...Wiring Diagrams Si18 525B 456 Appendix ...

Page 475: ...Si18 525B vi Index ...