D2CND0 D2CND0 D2TND0

D2TND0 D2TND024A4AA

Wall-mounted condensing boiler

ESIE17-09 / 2017.11

Servicing manual

36

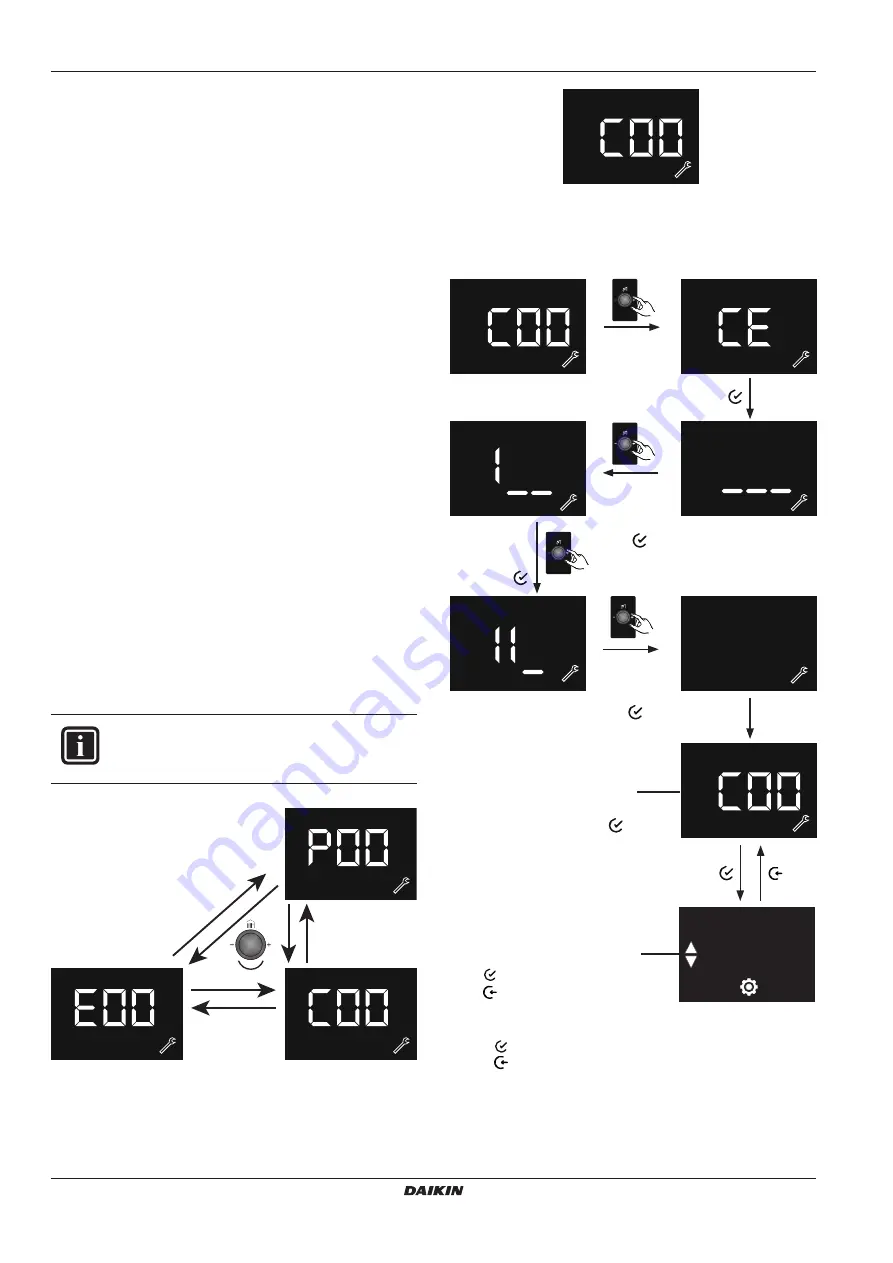

7.10.7.2 Entering SCOT Parameters

Enter the password (742) as indicated in page 30.

Select the C parameters as shown below.

INFORMATION

In this step, C parameters can not be changed. You can only

monitor the values of C parameters.

The parameters C00 to C05 can be adjusted by entering an

-

other password. To make these parameters adjustable, follow

the steps shown below;

7 Operation

By tuning left dial you can

scroll through between

P,C,E parameters.

Adjust first

digit to “1”

and then

push

Adjust third

digit to “5”

and then

push

a

a

b

Now, parameters

C00 - C05 are adjustable.

Select the parameter you

want to change and press

Adjust

second digit

to “1” and

then push

115

115

115

115

115

0

Change parameter value

with right dial.

After changing parameter

value;

Push to apply change

Push to cancel change

Select “CE”

C02:

Increasing this parameter value helps ignition problems

by increasing the ignition capacity. Factory setting is “0” (zero)

and adjustment will be done as trial and error in the field. 2%

increment is recommended at each trial. Too much increasing

may cause loud ignition.

C03:

This parameter is used to increase maximum allowable

flue duct length by increasing fan speed. Adjust this parameter

to “3” to use longer flue ducts for C13x and C33x types of flue

systems.

C04:

Minimum capacity of the boiler can be increased with

increasing this parameter value. In case there is a problematic

combustion at minimum capacity, this parameter should be

increased to overcome the problem.

C05:

This parameter is adjustable but after the adjustment,

the PCB will assign a value to this parameter, so adjusted

value will be corrected by the PCB automatically. This value

should be adjusted in case combustion is instable so, better

combustion will be initiated and PCB will assign the required

value itself afterwards.

C12:

This parameter can only be adjusted after manual cali

-

bration process (refer to section “Manual SCOT calibration”).

If CO2 percentage is below standard limits, this parameter

value must be increased to obtain a CO2 value inside the

limits (allowable CO2 limits are given at “technical specifica

-

tions”).

C13:

This parameter can only be adjusted after manual cali

-

bration process (refer to section “Manual SCOT calibration”).

If CO2 percentage is below standard limits at minimum ca

-

pacity, this parameter value must be increased to obtain a

CO2 value inside the limits (allowable CO2 limits are given at

“technical specifications”).

a Push

b Push