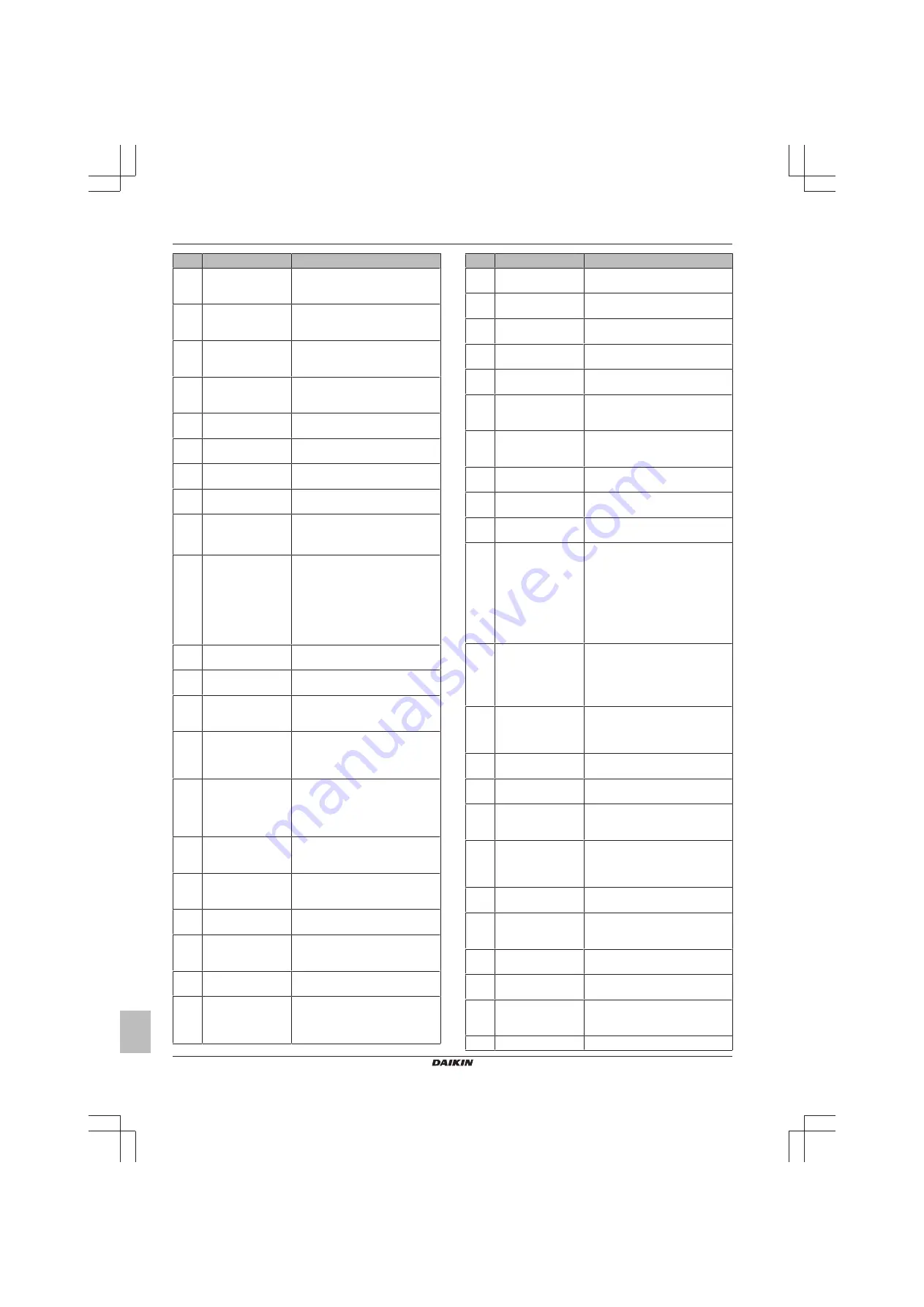

7 Error codes

Operation manual

10

D035A1/4AA + D035A4AA

Wall-mounted condensing boiler

3P469438-5D – 2017.06

#

Problem

Solution

12-65

Ignition SCOT

actuators fault does

not take place

Perform reset if needed. If problem

repeats, contact your service agent.

12-66

Ion base value

exceeds lower factory

limit

Perform reset. If problem repeats,

contact your service agent.

12-67

Ion base value

exceeds upper

factory limit

Perform reset. If problem repeats,

contact your service agent.

12-68

Ion base value differs

excessively from

previous value

Perform reset if needed. If problem

repeats, contact your service agent.

12-69

Offset adaption at

limit

Boiler continues operation but

contact your service agent.

12-70

Offset adaption not

executable

Boiler continues operation but

contact your service agent.

13-64

Fan speed error

Perform reset if needed. If problem

repeats, contact your service agent.

13-65

Fan speed error

Perform reset. If problem repeats,

contact your service agent.

16-64

Flue temperature

signalise overheating

Check flue gas discharge path.

Perform reset if needed. If problem

repeats, contact your service agent.

1J-64

High limit thermostat

signalise overheating

▪ Check the valves of the radiators

in the heating circuit.

▪ Check the combi boiler water

pressure. If it is low, fill the heating

circuit with water.

▪ Perform reset. If problem repeats,

contact your service agent.

80-01

Return temperature

sensor fault

Perform reset. If problem repeats,

contact your service agent.

81-01

Flow temperature

sensor fault

Perform reset. If problem repeats,

contact your service agent.

81-65

Domestic hot water

solar temperature

sensor fault

Boiler continues operation but solar

sensor is defective. Contact your

service agent.

8A-46

Freeze protection

Unit does not operate if flow

temperature sensor reads value less

than 1°C. Wait until the error code is

removed from the screen.

8H-64

Flow temperature

steep rise

Make sure radiator valves are open

enough to circulate water. Your

boiler will operate again after a while.

If problem repeats, contact your

service agent.

8H-65

Flow-return

temperature

difference too much

Make sure radiator valves are open

enough to circulate water. If problem

repeats, contact your service agent.

E1-64

Flame detection

before burner

operation

Perform reset. If problem repeats,

contact your service agent.

E1-65

Internal SCOT

system error

Perform reset if needed. If problem

repeats, contact your service agent.

E1-66

Calibration conditions

fault

No reset needed. Wait burner to

restart. If problem repeats, contact

your service agent.

E1-67

Missing calibration

Perform reset. If problem repeats,

contact your service agent.

E1-68

Ion base value is

outside the factory

limits or saved

incorrectly

Perform reset. If problem repeats,

contact your service agent.

#

Problem

Solution

E1-69

Parameter CRC error Perform reset. If problem repeats,

contact your service agent.

E1-70

Parameter CRC error Perform reset. If problem repeats,

contact your service agent.

E1-71

EK lockout failure

Permanent error. Contact your

service agent.

E1-72

SCOT flame amplifier Perform reset if needed. If problem

repeats, contact your service agent.

E1-73

Internal PCB error

Perform reset if needed. If problem

repeats, contact your service agent.

H9-01

Outside sensor fault

Boiler continues operation but

outside sensor is defective. Contact

your service agent.

HC-01

Domestic hot water

temperature sensor

fault

Boiler continues operation but you

must contact your service agent.

HJ-08

High system pressure Discharge water down to 0.8 bar.

(You can bleed the radiators.)

HJ-09

Low system pressure Increase the system pressure to

0.8 bar

HJ-10

Water pressure

sensor fault

Contact your service agent.

J6-01

Flow temperature

sensor overheating

(Can be a blocking

error or a lockout

error)

▪ Check the valves of the radiators

in the heating circuit.

▪ Check the combi boiler water

pressure. If it is low, fill the heating

circuit with water.

▪ Perform reset if needed. If problem

repeats, contact your service

agent.

J6-20

Return temperature

sensor overheating

(Can be a blocking

error or a lockout

error)

Perform reset if needed. If problem

repeats, contact your service agent.

J6-21

Return temperature is

higher than flow

temperature

No reset needed, burner operates

itself after a small amount of time. If

problem repeats, contact your

service agent.

JJ-64

Flue temperature

sensor fault

Perform reset. If problem repeats,

contact your service agent.

U2-01

Supply voltage is

below low limit

Contact your service agent.

U2-01

Supply voltage is

above high limit

Your boiler will continue operation

but you must contact your service

agent.

U4-65

Opentherm room

thermostat

connection is

defective

Your boiler will continue operation

but Opentherm room thermostat is

out of operation. Contact your

service agent.

U4-66

CAN-bus timeout

If problem repeats, contact your

service agent.

U4-67

Remote reset

supervision

Switch off - switch on power mains. If

problem repeats, contact your

service agent.

UA-64

Blocking during BCC

update process

Contact your service agent.

UA-65

PCB requires a BCC

update

Contact your service agent.

UA-66

BCC-ID of internal

EEPROM is

inconsistent

Contact your service agent.

UA-67

BCC is missing

Contact your service agent.