4 Installation

Installation Manual

15

D2CNL024A1AA

Wall-mounted condensing boiler

3P469346-12R – 2021.09

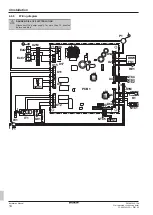

Symbols:

Item

Description

Option

Wiring depending on model

Switch box

PCB

Earth wiring

15

Wire number 15

Legend:

Part

Connector

Description

PCB1

—

Main PCB

P1

X1A - X11

Boiler pump

F1

X6A -X11

Fan

GV1

X12

Gas valve

IT1

X12

Ignition transformer

3WV1

X10

Central heating / domestic hot

water diverter valve motor

WPS1

X7

Water pressure sensor

DHW FS1

X2

Domestic hot water flow sensor

IE1

X12

Ionisation input

K1

X1M

On/Off room thermostat

HE1

X2

Overheat thermostat

NTC1

X1M

Outdoor temperature sensor

NTC2

X4

Flue temperature sensor

NTC3

X4

Return temperature sensor

NTC4

X4

Flow temperature sensor

NTC5

X7

Domestic hot water temperature

sensor

Ext2

X2M

Power supply cable

Ext3

X2M

External power output

(230 V AC)

WARNING

External power output should ONLY be used for optional

parts supplied by manufacturer, according to the

instructions provided within the manual of optional parts.

Failure to observe this warning will void the warranty. The

manufacturer is NOT responsible for any damage that may

occur this way.

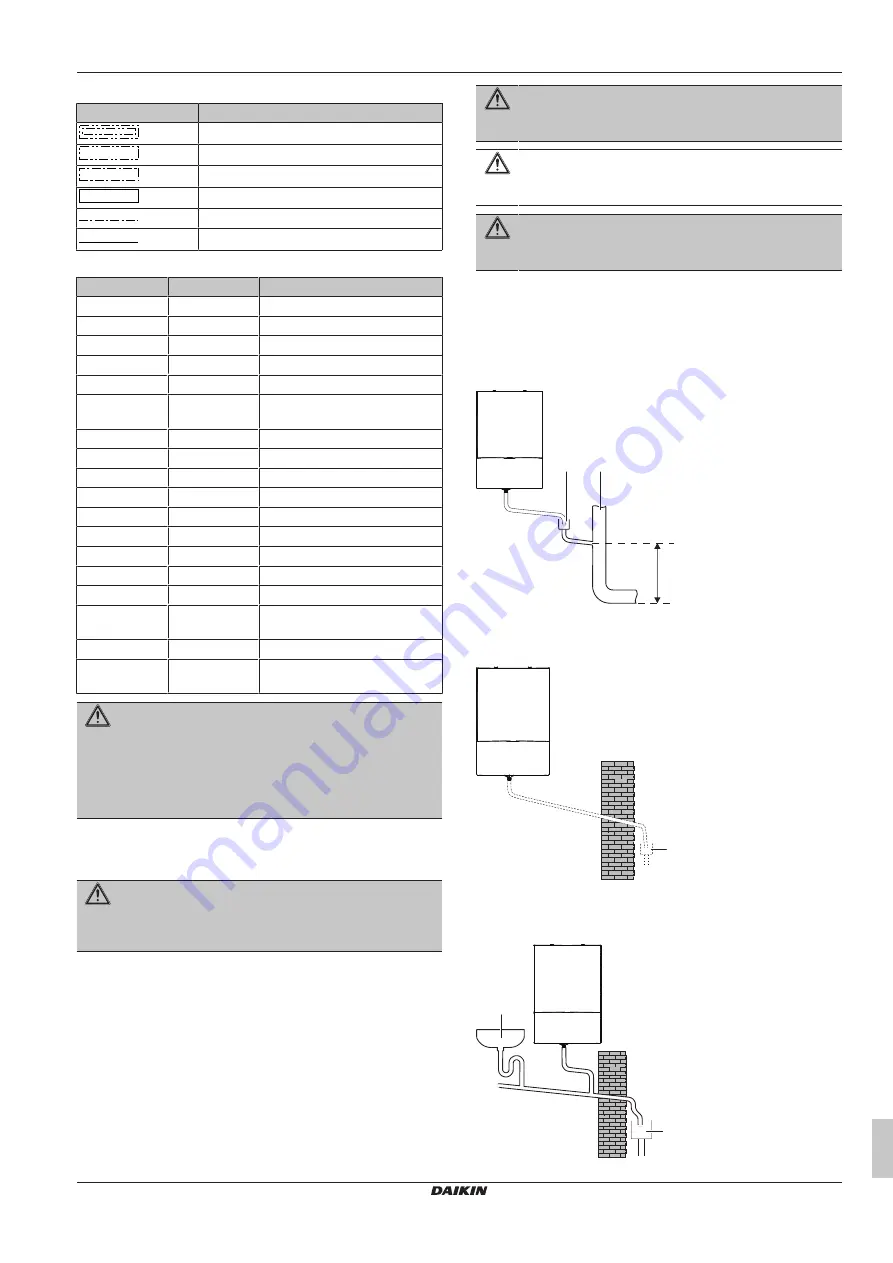

4.8.7

Guidelines when connecting the

condensate piping

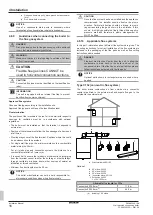

DANGER

In order to prevent escape of flue gases and so poisoning,

the condensate trap must be mounted to its place before

commissioning.

Condensate trap must be connected to a drain via an open

connection.

Precautions that should be taken about condensate piping are:

▪ Horizontal pipe runs must fall a minimum of 45 mm/metre.

▪ External piping should be kept as short as possible or thermally

insulated to prevent freezing, depending on the installation winter

climate condition.

▪ Make sure that the condensate disposal system, the piping, and

the fittings are made of acid resistant material like plastics.

WARNING

The condensate trap outlet shall NOT be modified or

blocked.

CAUTION

The condensate discharge piping diameter must be large

enough so as not to restrain the condensate water flow.

WARNING

If the discharge pipe is located outdoors, take measures

against frost.

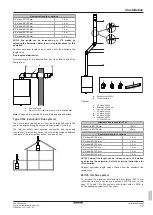

4.8.8

Guidelines for condensate piping

termination

Condensate piping can be connected to a termination in different

ways shown below:

Terminating into an internal soil and vent stack

b

a

≥450 mm

a

Air breaker

b

Internal soil and vent stack

Terminating into an external waste system

a

a

Open end direct into gully, below ground but above water

level

Terminating into an external purpose made soakaway

a

b