4 Installation

Installation Manual

20

D2CNL024A1AA

Wall-mounted condensing boiler

3P469346-12R – 2021.09

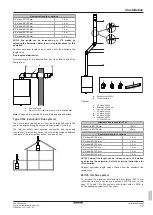

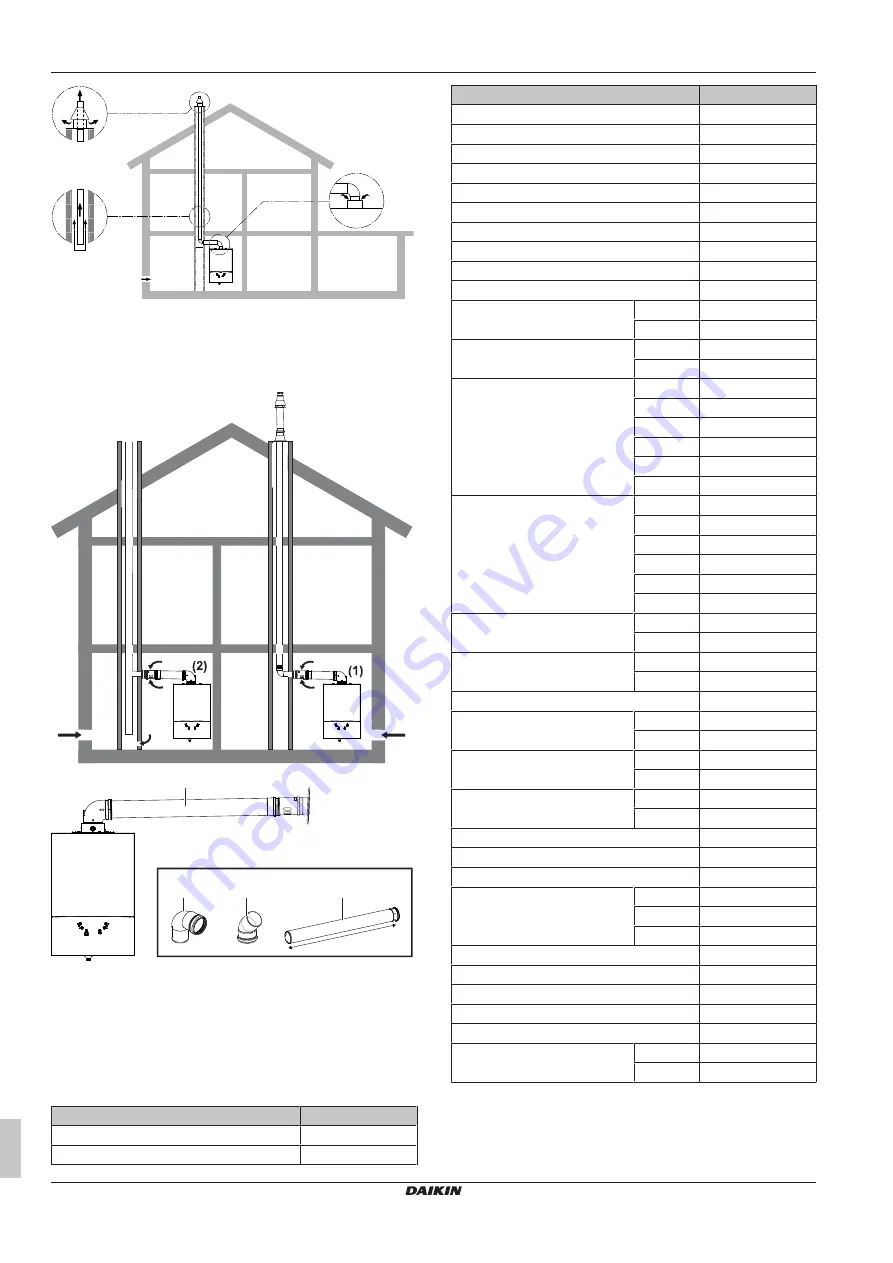

Type B33 (open flue system)

The multi served chimnet is a system that is a part of the building

and has a separate CE marking. The connection between the boiler

and the shaft must be obtained via Daikin.

b

c

a

d

L

Optional:

a

B33 flue kit

b

90° elbow 60 mm

c

45° elbow 60 mm

d

Extension 60 mm

Flue parts order codes

Required flue kits and/or additional parts can be ordered from Daikin

with the order codes given in the table below:

Flue part

Order code

Wall terminal kit 60/100 (C13x)

DRWTER60100AA

Wall terminal kit 80/125 (C13x)

EKFGW6359

Flue part

Order code

Roof terminal kit 60/100 (C33x)

EKFGP6837

Roof terminal kit 80/125 (C33x)

EKFGP6864

Tee 60/100 with measurement point

EKFGP4667

90° elbow 60/100 (boiler outlet)

DRMEEA60100BA

90° elbow 60/100

EKFGP4660

90° elbow 80/125

EKFGP4810

45° elbow 60/100

EKFGP4661

45° elbow 80/125

EKFGP4811

30° elbow 60/100

EKFGP4664

30° elbow 80/125

EKFGP4814

Extension duct 60/100

500 mm

EKFGP4651

1000 mm

EKFGP4652

Extension duct 80/125

500 mm

EKFGP4801

1000 mm

EKFGP4802

Tile roof outlet kit 60/100

18°/22°

EKFGS0518

23°/27°

EKFGS0519

25°/45°

EKFGP7910

43°/47°

EKFGS0523

48°/52°

EKFGS0524

53°/57

EKFGS0525

Tile roof outlet kit 80/125

18°/22°

EKFGT6300

23°/27°

EKFGT6301

25°/45°

EKFGP7909

43°/47°

EKFGT6305

48°/52°

EKFGT6306

53°/57°

EKFGT6307

Flat roof outlet kit

60/100

EKFGP6940

80/125

EKFGW5333

Wall bracket

DN.100

EKFGP4631

DN.125

EKFGP4481

60/100 to 80/125 adapter

DRDECO80125BA

Tee flex boiler connection set

100 mm

EKFGP6368

130 mm

EKFGP6215

Flex + support elbow

60/100

EKFGP6354

60/130

EKFGS0257

Chimney connection

60/100

EKFGP4678

80/125

EKFGS4828

Roof terminal kit 80 mm

EKFGP6864

90° elbow 80 mm

EKFGW4085

45° elbow 80 mm

EKFGW4086

Extension duct 80 mm

500 mm

EKFGW4001

1000 mm

EKFGW4002

2000 mm

EKFGW4004

60/100 to 80/80 adapter

DRDECOP8080BA

Air intake 80 mm (C53 kit)

EKFGV1102

Air intake 80 mm (C83 kit)

EKFGV1101

90° elbow 60 mm

DR90ELBOW60AA

45° elbow 60 mm

DR45ELBOW60AA

Extension duct 60 mm

500 mm

DREXDUC0500AA

1000 mm

DREXDUC1000AA