Table of contents

Installation Manual

3

D2CNL024A1AA

Wall-mounted condensing boiler

3P469346-12R – 2021.09

Table of contents

About the documentation ..........................................................

Meaning of warnings and symbols..............................

Identification label......................................................................

Symbols on the package ...........................................................

Safety systems ..........................................................................

Dimensions................................................................................

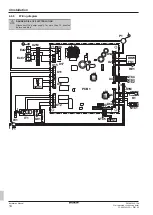

Components ..............................................................................

Technical specifications ............................................................

To open the unit ........................................................................

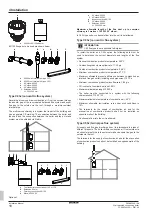

Installation site requirements.....................................................

Minimum installation clearances .................................

To unpack the unit.....................................................................

To mount the unit ......................................................................

Central heating system requirements........................................

Underfloor heating requirements...............................................

Residual pump lift graph............................................................

Connections ..............................................................................

Piping connections...................................................... 11

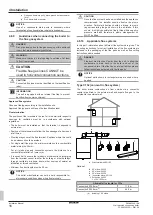

Guidelines when connecting the gas piping................ 11

Guidelines when connecting the water piping............. 12

Guidelines when connecting the electrical wiring ....... 12

Guidelines when connecting options to the boiler....... 13

Wiring diagram............................................................ 14

Guidelines when connecting the condensate piping... 15

Guidelines for condensate piping termination............. 15

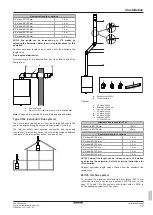

Applicable flue systems .............................................. 16

To fill the system with water ......................................................

To fill the condensate trap .........................................................

To check for gas leakage ..........................................................

To commission the unit .............................................................

To commission the central heating ............................. 22

To commission the central heating capacity setting ... 22

To commission the domestic hot water....................... 22

Disposal

Old units must be appropriately disposed of, in accordance with local

and national regulations. The components are easy to separate and

the plastics are marked. This allows the various components to be

sorted for appropriate recycling or disposal.

▪ Units are marked with the following symbol:

This means that electrical and electronic products may NOT be

mixed with unsorted household waste. Do NOT try to dismantle

the system yourself: the dismantling of the system, treatment of

the refrigerant, of oil and of other parts MUST be done by an

authorised installer and MUST comply with applicable legislation.

Units MUST be treated at a specialised treatment facility for reuse,

recycling and recovery. By ensuring this product is disposed of

correctly, you will help to prevent potential negative consequences

for the environment and human health. For more information,

contact your installer or local authority.

1

Introduction

1.1

About the documentation

The instructions contained in this document are intended to guide

you through the installation of the unit. Damage caused by non-

observance of these instructions are not under the responsibility of

Daikin.

▪ The original documentation is written in English. All other

languages are translations.

▪ The precautions described in this document are written for

installers and they cover very important topics. Follow them

carefully.

▪ Please read the operation manual and installation manual prior to

use and keep them for future reference.

1.1.1

Meaning of warnings and symbols

DANGER

Indicates a situation that results in death or serious injury.

WARNING

Indicates a situation that could result in death or serious

injury.

CAUTION

Indicates a situation that could result in minor or moderate

injury.

NOTICE

Indicates a situation that could result in equipment or

property damage.

INFORMATION

Indicates useful tips or additional information.

1.2

Identification label

You can find data about the unit on its identification label, which is

located at the bottom of the right cover of the unit.