2 Safety instructions

Installation Manual

4

D2CNL024A1AA

Wall-mounted condensing boiler

3P469346-12R – 2021.09

Pn (80/60)

Pn (50/30)

Qn

Qnw

D (

Δ

T=30 K)

PMS

PMW

Nox

kW

kW

kW

kW

l/min

bar

MPa

bar

MPa

/

/

XXXX-XX

PIN:

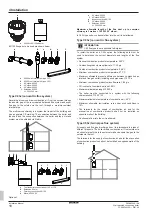

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

p

q

r

s

t

v

u

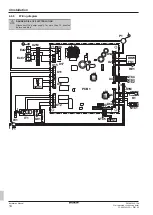

a

Product number

b

Electrical supply

c

Maximum electrical power consumption

d

Degree of protection

e

Nominal heat output range @ 80/60

f

Nominal heat output range @ 50/30

g

Nominal heat input range

h

Nominal heat input range (Domestic hot water)

i

Hot water amount @ DT=30

j

NOx class

k

Maximum central heating pressure (bar)

l

Maximum central heating pressure (MPa)

m

Maximum domestic hot water pressure (bar)

n

Maximum domestic hot water pressure (MPa)

o

Country of destination(s)

p

Serial number

q

Appliance type

r

Efficiency class

s

Gas category

t

Gas type and supply pressure

u

PIN number

v

Product type

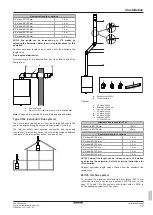

1.3

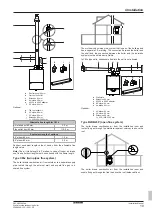

Symbols on the package

This is a fragile piece of equipment: Please provide a dry

storage space for the unit.

This is a fragile piece of equipment: Please be very careful

not to drop.

Store the unit in a flat position as indicated on the box.

No more than 5 boxes should be stacked on top of each

other.

MAX. 2

When stacking 6 boxes on one pallet, no more than 2

pallets should be stacked on top of each other.

MAX. 3

When stacking 4 boxes on one pallet, no more than 3

pallets should be stacked on top of each other.

2

Safety instructions

These instructions are exclusively designed for qualified competent

persons.

▪ Work on gas units must only be carried out by a qualified gas

fitter.

▪ Work on electrical equipment must only be carried out by a

qualified electrician.

▪ The system must be commissioned by a qualified competent

person.

WARNING

A qualified person shall explain the operating principles

and the use of the unit to the user. The user is NOT

allowed to perform any modifications, maintenance or

repairs on the unit, unless otherwise stated, or have the

such performed by unauthorised third parties. Otherwise,

the unit warranty becomes void.

DANGER

Isolate the boiler from the power mains before working on

it.

WARNING

Unit installation, commissioning, repair, configuration and

service MUST be performed by qualified competent

persons in accordance with local standards and

regulations. Incorrect installation of this unit may harm the

user and his/her surroundings. The manufacturer is NOT

responsible for any malfunctions and/or damage that may

occur this way.

DANGER

Flammable fluids and materials must be stored at least

1 metre away from the boiler.

WARNING

To ensure faultless operation, long term availability of all

functions and long working life of the boiler ONLY use

original spares.

3

About the unit

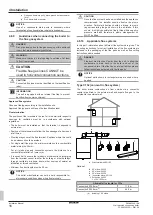

This Daikin unit is a wall-mounted gas-fired condensing boiler that

can supply heat to central heating systems, as well as supply

domestic hot water. Depending on settings, it is possible to use the

unit solely for hot water or solely for central heating. Hot water

supply type can be

instantaneous

or by means of a hot water

storage tank

.

Heating only

boilers do not supply domestic hot

water. The type of the boiler can be recognized from the model

name written on the identification label. See table below:

Model

Type

Domestic hot water

supply

Filling loop

D2CNL024A1AA

D2CNL024

Instantaneous

Internal

A control unit, which contains a user interface, controls the ignition,

safety systems, and other actuators. User interaction is provided via

that user interface, which is composed of an LCD screen and

buttons which is located on the front cover of the unit.

3.1

Safety systems

The unit is equipped with several safety systems, to protect it against

dangerous conditions:

Flue safety system

: This is controlled by the flue gas temperature

sensor located on the flue outlet part of the boiler. It is activated

when the flue gas temperature exceeds safety limits.

Overheating safety system

: This is controlled by the safety limiting

thermostat. It is located on the main heat exchanger and stops the

unit when the flow temperature reaches 100°C, to avoid boiling of

the water, which may damage the unit.