4 Installation

Installation manual

20

D035A1/4AA + D035A4AA

Wall-mounted condensing boiler

3P469346-5E – 2017.06

80/125 Vertical flue length can be increased up to 99 metres by

adjusting the parameter C3 to 5 from the user interface. Refer to

servicing instructions for this operation.

Subtract equivalent length value of bends from the allowable flue

length value.

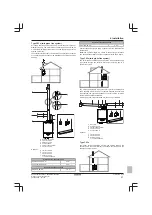

80/125 mm flue system

To increase the maximum allowable flue duct length, 80/125 mm

concentric flue ducts can be used instead of 60/100 mm. In this

case, C13x and C33x flue systems should start with a 60/100 to

80/125 adapter coupled to the flue outlet.

a

a

60/100 to 80/125 adapter

80/125 flue parts to be used are shown below:

a

b

c

d

e

f

a

80/125 wall terminal kit (type C13)

b

80/125 roof terminal kit (type C33)

c

90° elbow 80/125

d

45° elbow 80/125

e

30° elbow 80/125

f

Extension 80/125

L = 500-1000 mm

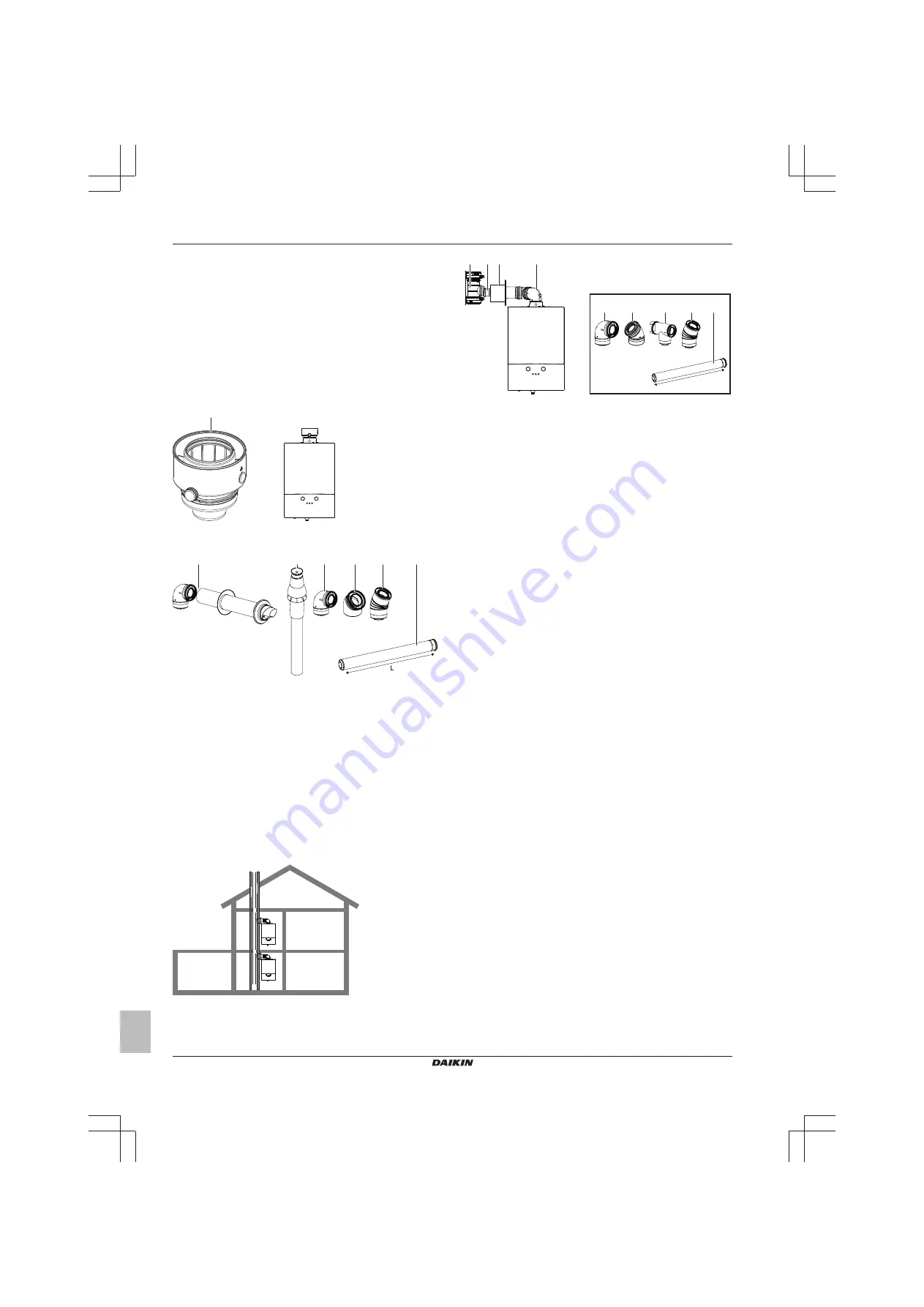

Type C43x (concentric flue system)

Several heat sources draw combustion air from the outside through

the annular gap of the room sealed balanced flue system and expel

flue gas to the outside via the roof, through a moisture-resistant

internal pipe.

The multi-served chimney is a system that is part of the building and

has a separate CE marking. The connection between the boiler and

the shaft and, the connection between the boiler and the air intake

system must be obtained via Daikin.

e

f

g

h

L

i

a b c

d

a

Tee flex boiler connection set 100 or 130

b

Extension 60 mm

c

Chimney connection 60/100

d

Elbow 60/100 90°

Optional:

e

90° elbow 60/100

f

45° elbow 60/100

g

Tee 60/100 with measurement point

h

30° elbow 60/100

i

Extension 60/100

L = 500-1000 mm

Maximum allowable length of the flue duct up to common

chimney is 2 1 60/100 90° elbow.

In C43x type units, condensate flow into the unit is not allowed.

Type C63x (concentric flue system)

To install the boiler as a C63x option the following data must be

used to determine the correct diameters and lengths of the flue

system.

for D2C/TND028

▪ Nominal combustion products temperature: 83.4°C

▪ Combustion products mass flow rate: 12.35 g/s

▪ Overheat combustion products temperature: 92.2°C

▪ Minimum combustion products temperature: 30.8°C

▪ Maximum allowable pressure difference between combustion air

inlet and flue gas outlet (including wind pressures): 135 Pa

for D2C/TND035

▪ Nominal combustion products temperature: 88.4°C

▪ Combustion products mass flow rate: 15.47 g/s

▪ Overheat combustion products temperature: 99.5°C

▪ Minimum combustion products temperature: 31.2°C

▪ Maximum allowable pressure difference between combustion air

inlet and flue gas outlet (including wind pressures): 185 Pa

for D2C/TND028 and D2C/TND035

▪ Minimum combustion products mass flow rate: 2.2 g/s

▪ CO

2

content at nominal heat input: 8.8%

▪ Maximum allowable draught: 50 Pa

▪ The boiler must be connected to a system with the following

characteristics: T120 P1 W

▪ Maximum allowable temperature of combustion air: 50°C

▪ Maximum allowable recirculation rate under wind conditions is

10%

▪ The terminals for the supply of combustion air and for the

evacuation of combustion products shall not be installed on

opposite walls of the building.

▪ Condensate flow into the unit is allowed.