6 Hand-over to the user

Installation manual

26

D035A1/4AA + D035A4AA

Wall-mounted condensing boiler

3P469346-5E – 2017.06

5.3

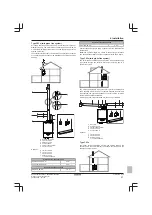

To check for gas leakage

DANGER

Before passing next steps, this control must be fulfilled.

1

Before connecting the unit to power mains, close valves 1, 2

and 3.

2

Connect a manometer to gas counter.

3

Open valves 1, 2 and 3.

4

Close valve 1.

5

Note the manometer measurement and wait for 10 minutes.

6

After 10 minutes, compare the manometer measurement with

the initial value. If the pressure is decreased, it means there is

gas leakage. Check the gas line and fittings.

7

Repeat this process until being sure that there is no leakage.

8

Close valve 1, remove the manometer and open valve 1 again.

1

2

3

5.4

To commission the unit

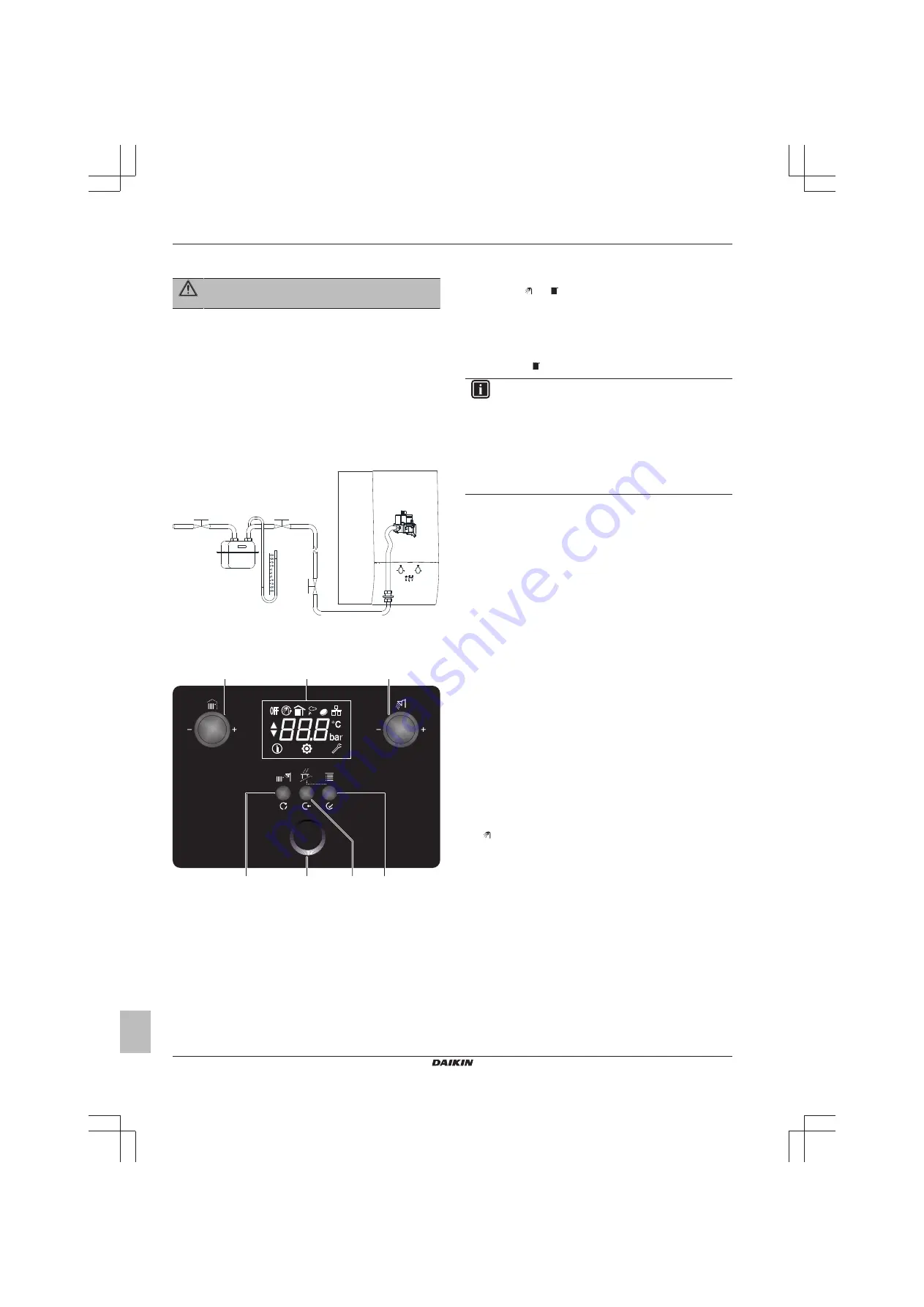

Legend - User interface:

a

e

f

g

c

b

d

a

Left dial

b

LCD screen

c

Right dial

d

Mode / Reset

e

Status indicator

f

Cancel / Back

g

Menu / Enter

1

Make sure the system is filled with water and fully vented as

described in this manual.

2

Check that the central heating and domestic hot water isolating

valves are open.

3

Check that gas service valve is open.

4

Connect the unit to the main power supply. The user interface

will be energised.

5.4.1

To commission the central heating

1

Set mode to winter mode via "Mode" button on the user

interface. ( and icons are displayed on the screen.)

2

Set central heating set temperature to maximum value via left

dial. If connected, make sure all external controls such as

outdoor sensor and room thermostat are calling for heat.

3

The boiler control now go through its ignition sequence. The

status indicator will glow constantly in blue if flame is

established. icon will blink when central heating is active.

INFORMATION

After first power ON, the boiler does not increase its

capacity above a preset value for about 12 minutes, even if

there is demand.

▪ First 0~2 minutes: The electronic gas adaptive system

calibrates itself.

▪ Next 8~10 minutes: The boiler performs the low water

temperature function. You can skip this function by

pressing the "Cancel" button for 5 seconds.

4

Press "Cancel" and "Menu" buttons together 5 seconds to

activate the sweeper mode. With sweeper mode, boiler can be

operated at maximum and minimum capacity independent of

heat demand.

5

"tst - 100" caption will appear on the screen. This means boiler

is operating at nominal capacity. Check nominal capacity

operation.

6

To quit sweeper mode, again press "Cancel" and "Menu"

buttons together five seconds. Sweeper mode will be

deactivated and boiler will return to normal operation mode.

Sweeper mode also finishes automatically after 15 minutes.

5.4.2

To commission the central heating

capacity setting

The boiler's central heating capacity can be adjusted form the

control panel. If the heat loss of installation is much less than that of

the boiler nominal capacity, it is recommended to reduce the boiler

nominal capacity to the installation capacity. Refer to service

instructions for this operation.

5.4.3

To commission the domestic hot water

(Only for models D2CND028 and D2CND035 )

1

Set domestic hot water set temperature to its maximum value

via right dial.

2

Open hot water taps fully and ensure that water flows freely

from them.

3

icon will blink when domestic water heating is active.

4

Measure the domestic hot water inlet temperature. (Cold water

drawn off from taps)

5

Check that domestic hot water temperature rise is around 34°C.

6

Hand-over to the user

After completing the installation and commissioning of the system

the installer should hand over to the householder.

▪ Hand the operation manual to the householder and inform them

about his/her responsibilities under the relevant national

regulations.

▪ Explain and demonstrate the lighting and shutting down

procedures.

▪ Explain the function and the use of the boiler heating and

domestic hot water controls.