4 Installation

Installation manual

10

D035A1/4AA + D035A4AA

Wall-mounted condensing boiler

3P469346-5E – 2017.06

a

a

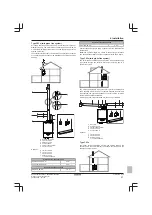

Vertical, flat wall

▪ The boiler can be installed outdoors in a partially protected

location. A partially protected location is a place where the boiler

is not exposed to the direct action and to the penetration of

atmospheric precipitation (rain, snow, hail,...).

The boiler can also be installed inside of an outside wall using the

appropriate in‑wall kit.

In case of outdoor installation, use the antifreeze kit

(DRANTIFREEZAA) to prevent the piping and condensate trap

from freezing.

▪ Flammable fluids and materials must be stored at least 1 metre

away from the boiler.

▪ The wall on which the unit is mounted should be strong enough to

carry the unit's weight. Build a reinforcement if necessary.

▪ The following minimum clearances are required for servicing:

180 mm above the casing*, 200 mm below, and 10 mm at each

side. 500 mm at the front clearance may be realised by opening a

cupboard door. See

"Minimum installation clearances" on

.

▪ For easier use of control panel, it is recommended that boiler

bottom is 1500 mm from the floor, for easier part replacement side

clearances should be 50 mm where applicable. See

installation clearances" on page 10

.

▪ If the boiler is installed in a room or compartment, it does not

require a dedicated ventilation for combustion air. If however

installed in a room containing a bath or a shower, then particular

reference is drawn to the current I.E.E. Wiring Regulations, local

Building Regulations or any other local regulations currently in

service.

▪ The intake air must not include chemicals that may cause

corrosion, toxic gas formation and even risk of explosion.

▪ If the wall on which the unit is mounted, is flammable, a non-

flammable material must be placed between the wall and the unit

and also at all locations through where the flue piping passes.

Minimum installation clearances

a

a

d

f

c

e

d

b

Minimum allowable clearances

a, sides

10 mm

b, Above the casing*

180 mm

c, below

255 mm

f, in front

500 mm

Recommended clearances for easy servicing

d, sides

50 mm

e, below (from the floor)

1500 mm

*

180 mm

is for the case that 60/100 90° elbow is connected

to the flue outlet of the boiler.

b = 270 mm

in case that 60/100 to 80/80 a 90°

elbow 80 are connected to the flue outlet of the boiler.

b = 280 mm

in case that 60/100 to 80/125 a 90°

elbow 80/125 are connected to the flue outlet of the boiler.

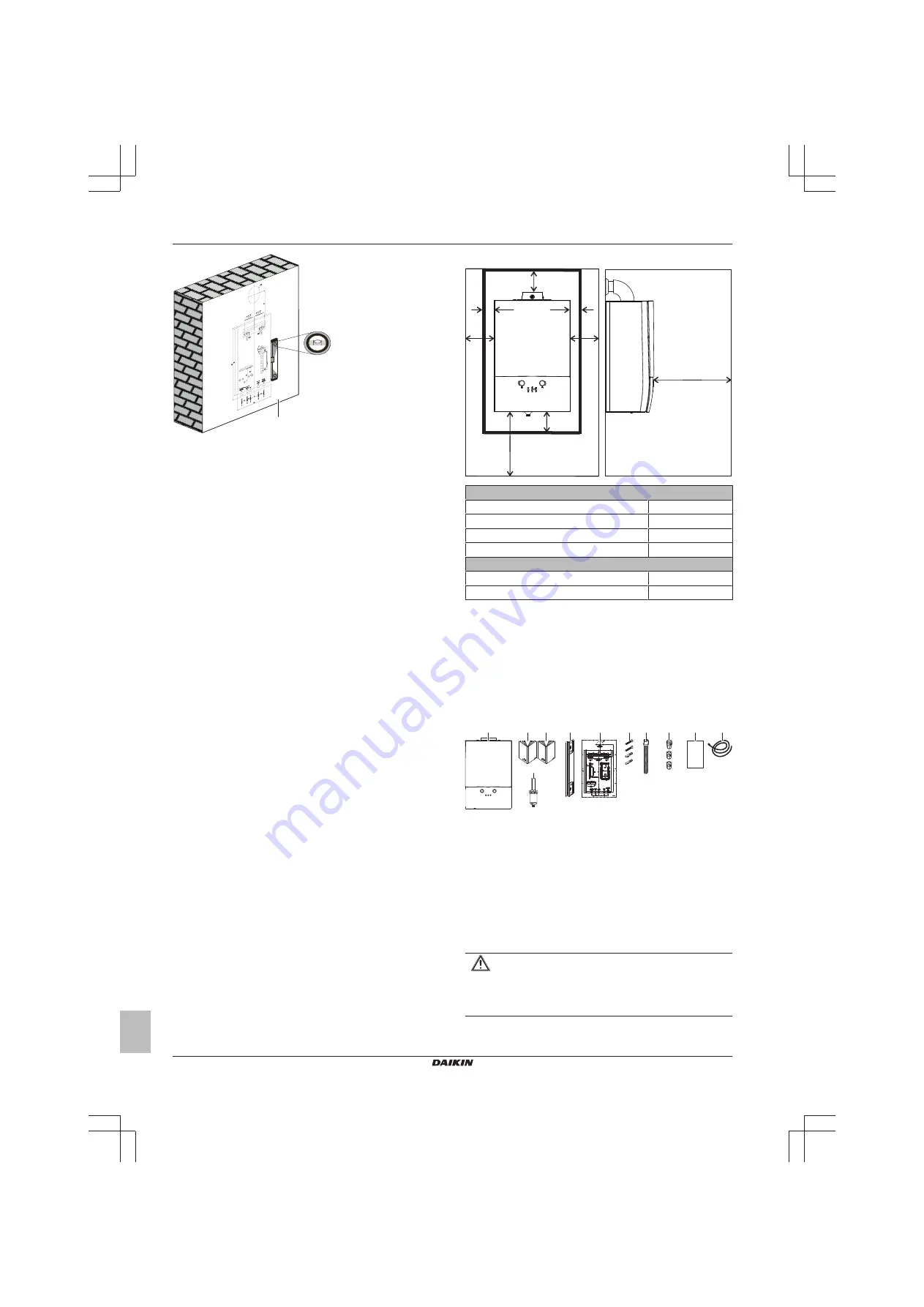

4.3

To unpack the unit

1

Unpack the unit as shown on top of the packing case. The

following items must be included in the package:

a

k

b

c

d

e

f

g

h

i

j

a

Combi boiler

b

Operation manual

c

Installation manual

d

Wall-mounting bracket

e

Installation template

f

Dowels and screws

g

Condensate hose

h

Cable glands 2×PG 7, 1×PG 9

i

Energy label

j

Storage tank temperature sensor (only for models

D2TND028A4AA and D2TND035A4AA)

k

Condensate trap

2

Check the contents of the package. If any of them is damaged

or missing, contact your dealer.

CAUTION

Store the remaining parts of the package (cardboard,

plastic, etc.) in a place children cannot reach. The

manufacturer is not responsible for any accidents and/or

damage that may occur this way.