4 Installation

Installation manual

14

D035A1/4AA + D035A4AA

Wall-mounted condensing boiler

3P469346-5E – 2017.06

▪ If old piping material does not have oxygen barrier, then it must be

separated from the boiler circuit via a plate heat exchanger and a

second pump has to be installed for necessary circulation.

▪ If the pressure reading on the boiler user interface is dropping

repeatedly, most probably there is a leakage in the installation.

Inspect the installation to repair.

▪ In case of solar preheating of the domestic hot water from a solar

tank, install the thermostatic mixing valve at the domestic hot

water outlet and inlet.

4.8.4

Guidelines when connecting the electrical

wiring

DANGER

Before working on the electrical circuit always isolate the

unit from the power mains.

WARNING

Only qualified persons are allowed to make electrical

connections on the unit. Failure to observe this warning will

void the warranty. The manufacturer is not responsible for

any damage that may occur this way.

WARNING

Use a dedicated power circuit. Never use a power supply

cable shared by another unit.

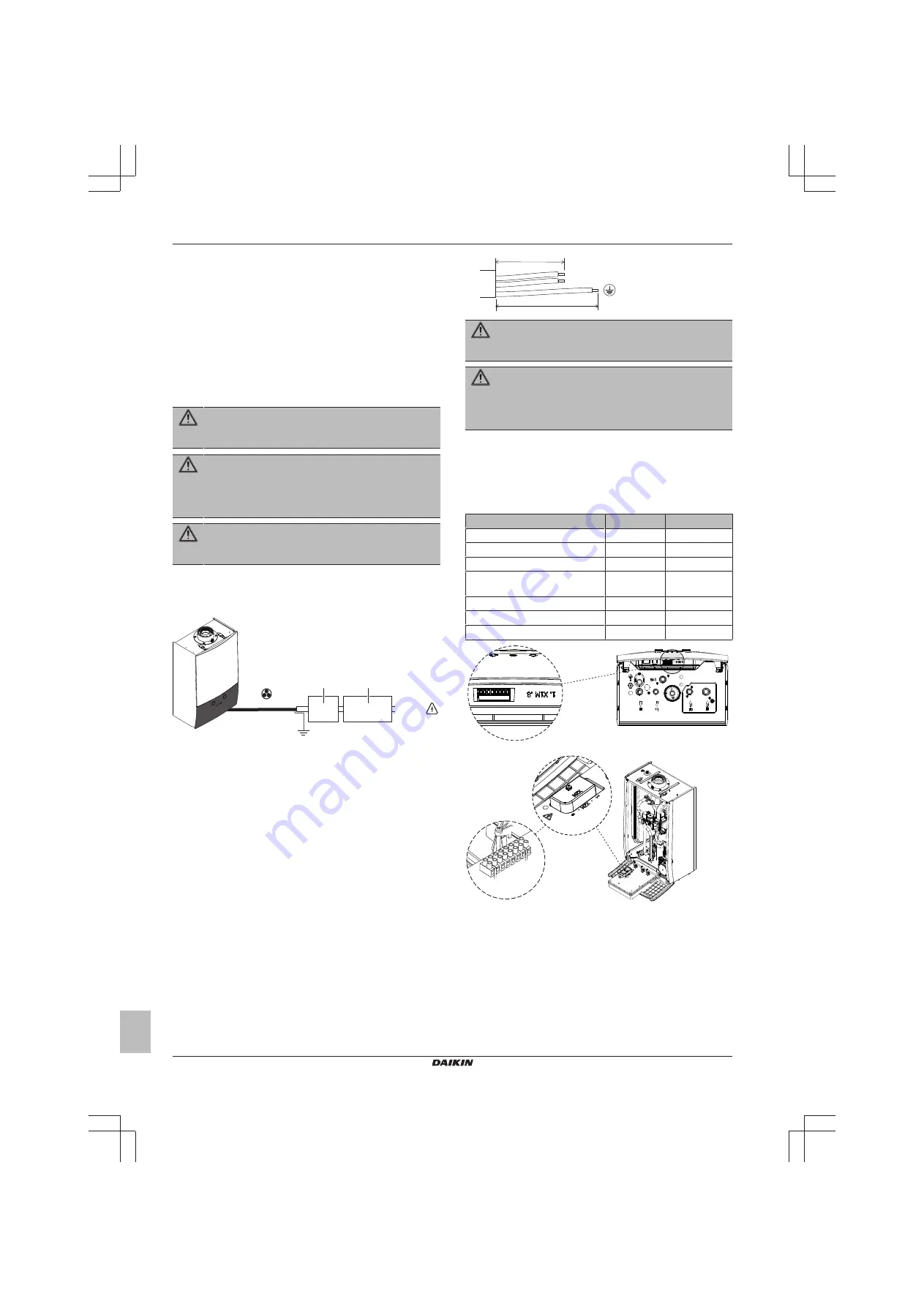

The unit runs on 230 V AC 50 Hz power. A power cable is delivered

with the package. The power cable must be connected to the power

supply by an electrician and in accordance with the applicable

legislation.

a

b

3×0.75 TTR / 230 V

H05RN

1~ 230 V

50 Hz

Cat. III

a

Safety breaker (2 A)

b

Earth leakage safety breaker

Cat. III

Overvoltage category III

▪ Electrical work should be carried out in accordance with the

installation manual and the national electrical wiring rules or code

of practice.

▪ Insufficient capacity or incomplete electrical work may cause

electrical shock or fire.

▪ A main switch or other means for disconnection, having a contact

separation in all poles providing full disconnection under

overvoltage category III, shall be installed in the fixed wiring.

▪ Be sure to establish an earth. Do not earth the unit to a utility pipe,

lightning arrester, or telephone earth.

Incomplete earth may

cause electrical shock and fire.

▪ While the electrical connections are being done, energy should

not be on the main power supply cable and the main switch

should be closed.

▪ During the electrical connections, make sure that the cables are

well-fixed and are connected firmly and tightly.

▪ Power supply cable must be equivalent to

H05RN-F (2451EC57)

as minimum requirement.

Observe the point mentioned below when wiring to the power supply

terminal board.

b

a

L

N

a<b

WARNING

Do not interchange the supply conductors L and the

neutral conductor N.

DANGER

Do not use gas and water pipes for earthing purposes and

ensure that they have not been used for this purpose

before. Failure to observe this relieves the manufacturer of

any responsibility.

4.8.5

Guidelines when connecting options to

the boiler

Optional equipment is connected to the connectors, which are

located on the outside of the switch box. Do not open the switch box

to connect optional equipment.

Temperature control units

Connector

Connection

Solar NTC sensor

X1M

1-2

Opentherm room thermostat

X1M

3-4

Outdoor sensor

X1M

5-6

Domestic hot water storage tank

sensor

X1M

7-8

External power output (230 V AC)

X2M

3-4

On-Off room thermostat

X2M

5-6

Solar stop contact

X2M

7-8

8

1

X2M

Wiring of the options that are to be connected to the X2M connector

must pop out from the inside of the unit via cable glands. Cable

glands that are sent with the unit must be assembled to the bottom

sheet of the boiler in case connection of these options. Below, you

can see the cable glands placement.