11

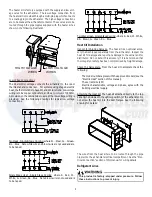

Regular Maintenance

The only item to be maintained on a regular basis by the user is

the circulating air filter(s). Filter should be cleaned or replaced

regularly.

HIGH VOLTAGE!

Disconnect ALL power before servicing or

installing this unit. Multiple power sources may

be present. Failure to do so may cause property

damage, personal injury or death.

Routine maintenance is essential for trouble free operation of

this Airhandler. A few preseason checks can eliminate costly

repairs and down time.

A certified service technician must perform all services

mentioned below.

1.

Check and change air filters as needed

2.

Check, adjust or replace belts and check sheaves for

proper operation.

3.

Clean the evaporator coil and check for duct leaks.

4.

Check for proper charge and (or) for refrigerant leaks.

If these few precautions are observed and maintained, this

Airhandler can provide years of trouble free service.