13

*Apply force to the center of the span.

t = Span length, inches

C = Center distance, inches

D = Larger sheave diameter, inches

d = Smaller sheave diameter, inches

h = Deflection height, inches

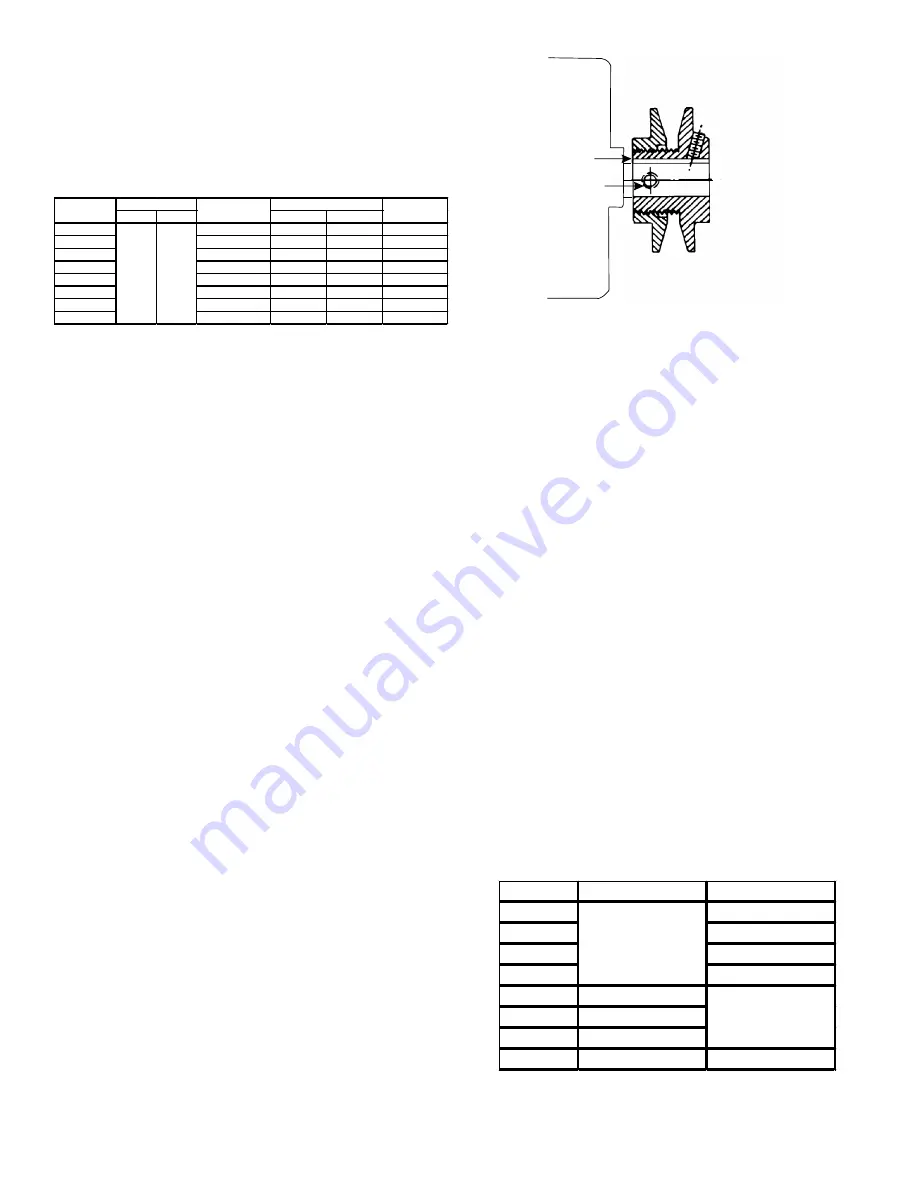

DRIVE BELT TENSION ADJUSTMENT

BELT

DRIVE

Used

New

DBH/DBC090*V

2.6 to 3.6

4.5+/-.5

5.5+/-.5

1/4+/-1/16

DBH/DBC090*S

3.0 to 4.0

4.5+/-.5

5.5+/-.5

1/4+/-1/16

DBH/DBC102*V

2.6 to 3.6

4.5+/-.5

5.5+/-.5

1/4+/-1/16

DBH/DBC102*S

3.0 to 4.0

4.5+/-.5

5.5+/-.5

1/4+/-1/16

DBH/DBC120*V

2.6 to 3.6

4.5+/-.5

5.5+/-.5

1/4+/-1/16

DBH/DBC120*S

3.0 to 4.0

4.5+/-.5

5.5+/-.5

1/4+/-1/16

DBC150*V

3.0 to 4.0

4.5+/-.5

5.5+/-.5

1/4+/-1/16

DBC150*S

4.2 to 5.2

4.5+/-.5

5.5+/-.5

1/4+/-1/16

A

Standard

MODEL

DEFLECTION

(in)

TYPE

SHEAVE

DIAMETER (d) (in)

DEFLECTION FORCE (lbs)

Recommended Pounds of Force Per Belt

When new V-belts are installed on a drive the initial

tension will drop rapidly during the first few hours. Check

tension frequently during the first 24 hours of operation.

Subsequent re-tensioning should fall between the minimum

and maximum force. To determine the deflection distance

from the normal position, use a straightedge or stretch a

cord from sheave to sheave to use as a reference line. On

multiple belt drives, an adjacent undeflected belt can be

used as a reference.

MOTOR SHEAVE ADJUSTMENTS

Vl, Vm & 2vp Variable Pitch Key Type Motor

Sheaves

The driving and driven sheaves should be in alignment with

each other and the shafts parallel.

Vl & Vm Sheaves Adjustment

1.

Loosen set screw “B” using a 5/32” Allen key.

2. Making half or full turns from closed position, adjust

sheave pitch diameter for desired speed. DO NOT

OPEN MORE THAN SIX FULL TURNS.

3.

Tighten set screw “B” securely over flat.

4. Carefully put on belts and adjust belt tension. DO

NOT FORCE BELTS OVER GROOVES.

5.

Ensure all keys are in place and the set screws tight

before starting drive. Recheck set screws and belt

tension after 24 hours service.

NOTE: Future adjustments should be made by

loosening the belt tension and increasing or

decreasing the pitch diameter of the sheave by

half or full turns as required. Readjust belt

tension before starting drive.

C

B

VL & VM

NOTE: Do not operate sheave with flange

projecting beyond the hub end.

Electrical Input Check

Make preliminary check of evaporator fan ampere draw

and verify that motor nameplate amps are not exceeded. A

final check of amp draw should be made upon completion

of air balancing of the duct system (see Appendix B).

Refrigeration System Checks

Heat pump units are equipped with thermal expansion

valves.

Ensure the hold-down bolts on the compressor are secure

and have not vibrated loose during shipment. Check

that the vibration grommets have been installed and

visually check all piping for damage and leaks and repair

if necessary. The entire system has been factory charged

and tested, making it unnecessary to field charge. Factory

refrigerant charge is shown on the unit’s nameplate.

To confirm charge levels or, if a leak occurs and charge

needs to be added to the system, it is recommended to

evacuate the system and recharge refrigerant to the unit’s

nameplate specifications. This unit has been rated in

the cooling mode at the AHRI rated conditions of: indoor

(80°F db/67°F wb) and outdoor (95°F db). While operating

at this condition, the superheat (measured at the suction

service port located near the compressor) or the subcool

(measured at the outdoor liquid line port) should be within

the range given in the following table.

Unit

Subcool (°F)

Superheat (°F)

DBC090*

11 to 15

DBC102*

10 to 14

DBC120*

10 to 14

DBC150*

11 to 17

DBH090*

3 to 7

DBH102*

13 to 17

DBH120*

9 to 13

DBH150*

10 to 14

20 to 25

N/A

10 to 15

Summary of Contents for DBC Series

Page 44: ...44...

Page 45: ...45...

Page 46: ...46 THIS PAGE IS INTENTIONALLY LEFT BLANK...