20

Accessories Wiring

If it is necessary for the installer to supply additional line volt-

age wiring to the inside of the furnace, the wiring must conform

to all local codes, and have a minimum temperature rating of

105°C. All line voltage wire splices must be made inside the

furnace junction box.

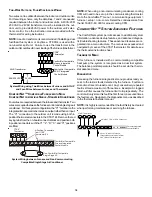

The integrated control module single humidifier terminal (HUM)

is energized with 115 volts whenever the induced draft blower

is energized. This terminal can also be used to provide 115 volt

power to a humidifier transformer. The remaining primary trans-

former wire would be connected to the Line N on the control

board.The integrated control module electronic air cleaner

terminal (EAC) is energized with 115 volts whenever the circu-

lator blower is energized.

In addition, the control is equipped with a dedicated humidifica-

tion relay which is available through ¼ inch terminals HUM-IN

and HUM-OUT. Similar to the HUM terminal, when utilizing

legacy connections, this relay will be closed during normal

heating operation. HUM IN must be powered with the desired

voltage (24 vac from the R terminal or 115 vac from L1 terminal).

The internal relay will close during a call for heat. Also, the

control can provide additional humidification features when wired

to a communicating thermostat (1, 2, R, C connections). If the

communicating thermostat is not capable of providing a hu-

midification call, this dedicated relay will function exactly as

mentioned above with a legacy setup. If the communicating

thermostat is capable of providing a humidification call the user

is now provided with 3 modes of operations which can be se-

lected within the thermostat user menu.

1. ON: Humidifier is turned on with a heat demand.

2. OFF: Humidifier remains off (relay never closes).

3. IND: Humidifier will cycle with humidification demand,

independent of heat demand. This mode allows the user

to select one of 4 fan speeds (25, 50, 75, and 100%).

NEUTRAL

HU

M

-OU

T

HUM-

IN

24 V

OLT

H

UMIDIFIER

A 24 volt humidifier can be powered by feeding one of the HUM

terminals with a field installed wire from the R terminal or by

connecting to the NO side of the low fire pressure switch.

A

UXILIARY

A

LARM

S

WITCH

The control is equipped with a 24VAC Auxiliary Alarm Input (12

inch purple wire attached to pin 6 of 15 pin connector) which

can be utilized with communicating mode setups (typically used

for condensate switch wiring but could be used with compat-

ible C0

2

sensors or Fire Alarms).

Legacy mode use

In a legacy system (Non-communicating), this auxiliary alarm

input is not operational. Any auxiliary alarm switch must be

used to interrupt Y1 signal either to IFC or to UC.

Communication mode use

This feature can be activated or deactivated through the ther-

mostat user menus. By default, an AUX switch is normally

closed and opens when the water level in the evaporator coil

base pan reaches a particular level. The control will respond by

turning off the outdoor compressor and display the proper fault

codes. If the AUX switch is detected closed for 30 seconds,

normal operation resumes and error messages are no longer

displayed. Installer must wire control voltage (24VAC) to AUX

switch to ensure the Auxiliary Alarm Input has 24VAC during

normal operation.

G

AS

S

UPPLY

AND

P

IPING

The furnace rating plate includes the approved furnace gas in-

put rating and gas types. The furnace must be equipped to

operate on the type of gas applied. This includes any conver-

sion kits required for alternate fuels and/or high altitude.

CAUTION

T

O

PREVENT

UNRELIABLE

OPERATION

OR

EQUIPMENT

DAMAGE

,

THE

INLET

GAS

SUPPLY

PRESSURE

MUST

BE

AS

SPECIFIED

ON

THE

UNIT

RATING

PLATE

WITH

ALL

OTHER

HOUSEHOLD

GAS

FIRED

APPLIANCES

OPERATING

.

Inlet gas supply pressures must be maintained within the ranges

specified in the following table. The supply pressure must be

constant and available with all other household gas fired appli-

ances operating. The minimum gas supply pressure must be

maintained to prevent unreliable ignition. The maximum must

not be exceeded to prevent unit overfiring.