14

standard “S636”. The primer and cement used must be of

the same manufacturer as the vent system. For Royal Pipe

System 636, use GVS-65 Primer (Purple) and GVS-65 PVC

Solvent Cement. For IPEX System 636, use PVC/CPVC

Primer, Purple or clear. Use PVC Solvent Cement (Gray).

For Canadian installations, ABS may be used as a

combustion air pipe only. ABS is not an approved vent

material in Canada.

If ABS is used as a combustion air pipe, it must be CSA

certified. Always follow the manufacturer’s instructions in the

use of primer and cement. Do not use primer and cement

around potential sources of ignition. Do not use primer or

cement beyond its expiration date.

The safe operation, as defined by ULC S636, of the vent

system is based on following these installation instructions,

the vent system manufacturer’s installation instructions,

and proper use of primer and cement. It is recommended

under this standard, that the vent system be checked once

a year by qualified service personnel. All fire stops and

roof flashings used with this system must be UL listed.

Acceptability under CAN/CSA B149.1-15 is dependent upon

full compliance with all installation instructions. Consult

the authority having jurisdiction (gas inspection authority,

municipal building department, fire department, etc.) before

installation to determine the need to obtain a permit.

*IPEX

System 636™ is a trademark of IPEX Inc

.

Carefully follow the pipe manufacturers’ instructions for

cutting, cleaning, and solvent cementing PVC and/or ABS.

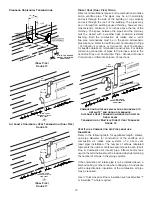

The vent can be run through an existing unused chimney

provided the space between the vent pipe and the chimney

is insulated and closed with a weather-tight, corrosion-

resistant flashing.

Standard Furnace Connections

It is the responsibility of the installer to ensure that the

piping connections to the furnace are secure, airtight, and

adequately supported.

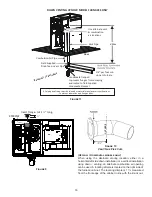

Vent/Flue Pipe

The vent pipe outlet is sized to accept 2” pipe. Secure vent/

flue pipe directly into the furnace fitting with the appropriate

glue. Alternately, a small section of 2” pipe may be glued

in the furnace socket and a rubber coupling installed to

allow removal for future service. Combustion Air and Vent

piping should be routed in a manner to avoid contact with

refrigerant lines, metering devices, condensate drain

lines, etc. If necessary, clearances may be increased by

creating an offset using two 45 degree elbows. This joint

can be rotated on the fitting to establish maximum clearance

between refrigerant lines, metering devices, and condensate

drain lines, etc. This joint is the equivalent of one 90 deg.

elbow when considering elbow count. (Figure 8A).

45 DEGREE

ELBOWS

Increased Clearance Configuration

Figure 8A

NOTE:

For

non-direct vent

installations, a minimum of one

90° elbow should be installed on the combustion air intake

coupling to guard against inadvertent blockage.

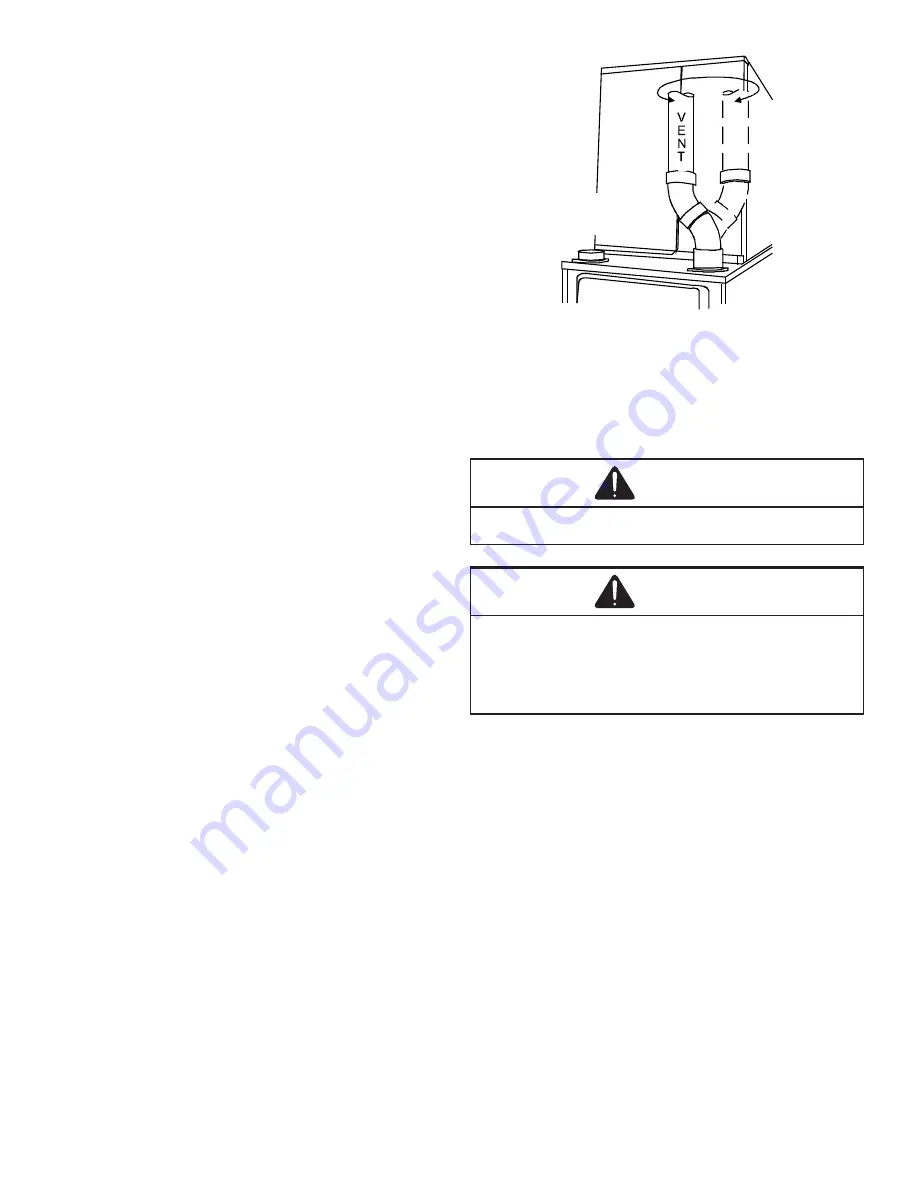

Direct Vent Installations

WARNING

Be sure not to damage internal wiring or other components

when reinstalling coupling and screws.

WARNING

The rubber elbow is not designed to support a load. When

the rubber elbow is mounted externally to the furnace

cabinet, extreme care must be taken to adequately support

field-supplied vent/flue piping, as damage can result in leaks

causing bodily injury or death due to exposure to flue gases

including carbon monoxide.

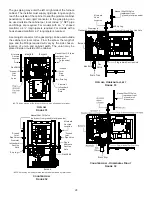

On

upflow

units secure the combustion air intake pipe to

the air intake coupling by using a take apart rubber coupling

supplied with the furnace or a plastic coupling. Also, the

intake coupling may be inverted to allow the intake pipe to

be glued directly to it. After inverting the coupling, secure it to

the furnace top with screws. On

counterflow

units secure the

combustion air intake pipe to the air intake coupling using

the rubber coupling and worm gear hose clamps provided

with the unit. The counterflow rubber coupling allows service

removal of air intake piping internal to the furnace blower

compartment. The combustion air intake pipe can also

be secured directly to the counterflow unit air intake pipe

coupling.