12

In addition to PVC and ABS pipe and fittings, Innoflue® by

Centrotherm Eco Systems and PolyPro® by M&G Duravent

are also approved vent and combustion air materials for

installations in the U.S.A. and Canada. Manufacturers

Installation instructions for these products must be followed.

These products have specific instructions for installing,

joining and terminating. Do not mix materials or components

of one manufacturer with materials or components of another

manufacturer.

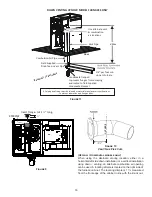

All furnaces are manufactured with 2” vent / intake pipe and

connectors. For furnaces requiring installation of 3” pipe,

the transition from 2” to 3” should be done as close to the

furnace as practically possible.

This furnace must not be connected to Type B, BW, or L vent

or vent connector, and must not be vented into any portion

of a factory built or masonry chimney except when used as

a pathway for PVC as described later in this section. Never

common vent this appliance with another appliance or use

a vent which is used by a solid fuel appliance. Do not use

commercially available “no hub connectors” other than those

shipped with this product.

It is the responsibility of the installer to follow the

manufacturers’ recommendations and to verify that all vent/

flue piping and connectors are compatible with furnace

flue products. Additionally, it is the responsibility of the

installer to ensure that all piping and connections possess

adequate structural integrity and support to prevent flue pipe

separation, shifting, or sagging during furnace operation.

Dual Certification: Non-Direct/Direct Vent

WARNING

To avoid bodily injury, fire or explosion solvent cements

must be kept away from all ignition sources (i.e., sparks, open

flames, and excessive heat) as they are combustible liquids.

Avoid breathing cement vapors or contact with skin and/or

eyes.

This furnace is dual certified and may be installed as a non-

direct vent (single pipe) or direct vent (dual pipe) appliance.

A non-direct vent installation requires only a vent/flue pipe,

while a direct vent installation requires both a vent/flue pipe

and a combustion air intake pipe. Refer to the appropriate

section for details concerning piping size, length, number of

elbows, furnace connections, and terminations.

Materials and Joining Methods

Two-three-inch nominal diameter PVC Schedule 40

pipe meeting ASTM D1785, PVC primer meeting ASTM

F656, and PVC solvent cement meeting ASTM D2564

specifications must be used. Fittings must be DWV type

fittings meeting ASTM D2665 and ASTM D3311. Carefully

follow the manufacturer’s instructions for cutting, cleaning,

and solvent cementing of PVC.

The use of Schedule 40 PVC cellular core DWV meeting

ASTM F891-1 or ABS cellular core (Foam Core) plastic pipe

is also acceptable as a flue/vent and intake pipe material.

PVC primer meeting ASTM F656 and PVC solvent cement

meeting ASTM D2564 specifications must be used. Fittings

must be DWV type fittings meeting ASTM D2665 and ASTM

D3311. Carefully follow the manufactures instructions for

cutting, cleaning and solvent cementing of PVC.

For Canadian installations: field supplied PVC venting

materials must be UL S636 listed.

NOTE:

Requirement does not apply to the combustion air

pipe.

As an alternative to PVC pipe, primer, solvent cement, and

fittings, ABS materials which are in compliance with the

following specifications may be used. Two-or-three-inch

ABS Schedule 40 pipe must meet ASTM D1527 and, if used

in Canada, must be CSA listed. Solvent cement for ABS to

ABS joints must meet ASTM D2235 and, if used in Canada,

must be CSA listed. The solvent cement for the PVC to ABS

transition joint must meet ASTM D3138. Fittings must be

DWV type fittings meeting ASTM D2661 and ASTM D3311

and, if used in Canada, must be CSA listed. Carefully follow

the manufacturers’ instructions for cutting, cleaning, and

solvent cementing PVC and/or ABS.

All 90° elbows must be medium radius (¼ bend DWV) or

long radius (Long sweep ¼ bend DWV) types conforming

to ASTM D3311. A medium radius (¼ bend DWV) elbow

measures 3 1/16” minimum from the plane of one opening to

the center line of the other opening for 2” diameter pipe, and

4 9/16” minimum for 3” pipe.

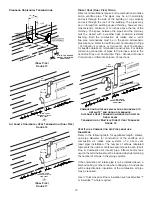

Proper Vent/Flue and Combustion

Air Piping Practices

Adhere to these instructions to ensure safe and proper

furnace performance. The length, diameter, and number of

elbows of the vent/flue pipe and combustion air pipe (when

applicable) affects the performance of the furnace and must

be carefully sized. All piping must be installed in accordance

with local codes and these instructions.

Some models require the use of 3” pipe. Do not transition

from a 2” to 3” pipe in a horizontal section of pipe as this may

create a water trap.

PREFERRED

Figure 4