31

AUX OUT

AUX IN

L1

NEUTRAL

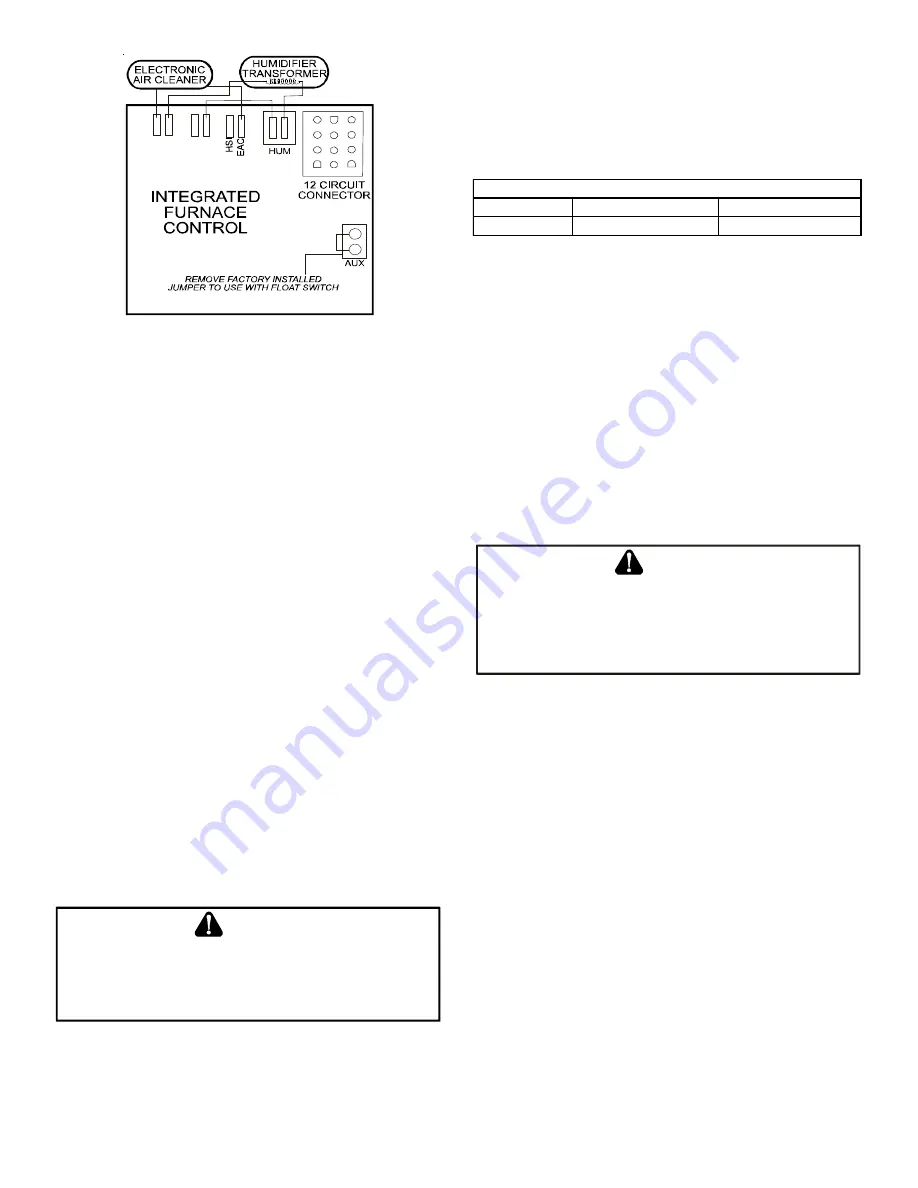

Accessories Wiring

Figure 35

If it is necessary for the installer to supply additional line voltage

wiring to the inside of the furnace, the wiring must conform to

all local codes, and have a minimum temperature rating of 105°C.

All line voltage wire splices must be made inside the furnace

junction box.

The furnace control board HUM (dry contacts) are closed

whenever the inducer is energized in a non-communicat-

ing installation. When used with a CTK02**, CTK03 or

CTK04 communicating thermostat, the HUM terminals are

closed whenever there is a call for humidity when this

feature is enabled in the communicating thermostat. In

the CTK03AB & CTK04** humidity must be enabled in he

main menu, se up in the Installer menu & ComfortNet

user menu. The integrated control module electronic air

cleaner terminals (EAC) are energized with 115 volts when-

ever the circulator blower is energized.

24 V

OLT

H

UMIDIFIER

A 24 volt humidifier can be powered by feeding one of the

HUM terminals with a field installed wire from the R ter-

minal.

G

AS

S

UPPLY

AND

P

IPING

The furnace rating plate includes the approved furnace gas input

rating and gas types. The furnace must be equipped to operate

on the type of gas applied. This includes any conversion kits

required for alternate fuels and/or high altitude.

CAUTION

T

O

PREVENT

UNRELIABLE

OPERATION

OR

EQUIPMENT

DAMAGE

,

THE

INLET

GAS

SUPPLY

PRESSURE

MUST

BE

AS

SPECIFIED

ON

THE

UNIT

RATING

PLATE

WITH

ALL

OTHER

HOUSEHOLD

GAS

FIRED

APPLIANCES

OPERATING

.

Inlet gas supply pressures must be maintained within the ranges

specified in the following table. The supply pressure must be

constant and available with all other household gas fired appli-

ances operating. The minimum gas supply pressure must be

maintained to prevent unreliable ignition. The maximum must

not be exceeded to prevent unit overfiring.

Natural Gas

Minimum: 4.5" w.c.

Maximum: 10.0" w.c.

Propane Gas

Minimum: 11.0" w.c.

Maximum: 13.0" w.c.

Inlet Gas Supply Pressure

A heat pump thermostat with

three stages of heat

is required

to properly use a two-stage furnace in conjunction with a

heat pump. Refer to the fossil fuel kit (AFE18-60A) installa-

tion instructions for additional thermostat requirements.

H

IGH

A

LTITUDE

D

ERATE

In some areas the gas supplier may artificially derate the gas

in an effort to compensate for the effects of altitude. If the

gas is artificially derated, the appropriate orifice size must be

determined based upon the BTU/ft

3

content of the derated

gas and the altitude. Refer to the National Fuel Gas Code,

NFPA 54/ANSI Z223.1 or CAN/CSA B149.1-15 in Canada, and

information provided by the gas supplier to determine the

proper orifice size.

P

ROPANE

G

AS

C

ONVERSION

WARNING

P

OSSIBLE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

MAY

OCCUR

IF

THE

CORRECT

CONVERSION

KITS

ARE

NOT

INSTALLED

. T

HE

APPROPRIATE

KITS

MUST

BE

APPLIED

TO

ENSURE

SAFE

AND

PROPER

FURNACE

OPERATION

. A

LL

CONVERSIONS

MUST

BE

PERFORMED

BY

A

QUALIFIED

INSTALLER

OR

SERVICE

AGENCY

.

As shipped, this unit is configured for natural gas. The LPM-

09 is required to convert this furnace to operate on LP

gas.

The correct kit must be used to insure safe and proper fur-

nace operation. All conversions must be performed by a quali-

fied installer, or service agency.

G

AS

V

ALVE

This unit is equipped with a 24 volt gas valve which modulates

by pneumatic linkage to the combustion air blower. Taps for

measuring the gas supply pressure and manifold pressure are

provided on the valve. This is a non-convertible, non-adjust-

able gas valve equipped for natural gas.

The gas valve has a manual ON/OFF control located on the

valve itself. This control may be set only to the “ON” or

“OFF” position. Refer to the lighting instructions label or the

Startup Procedure & Adjustment

section of this manual for

use of this control during start up and shut down periods.