56

SERVICING

Natural Gas

Minimum 4.5" w.c.

Maximum 10" w.c.

L.P. Gas

Minimum 10" w.c.

Maximum 13" w.c.

Inlet Gas Supply Pressure

Inlet Gas Supply Pressure

WARNING

D

ISCONNECT ELECTRICAL POWER AND SHUT OFF GAS SUPPLY.

1. Turn off gas supply to the furnace at the manual gas

shutoff valve external to the furnace.

2. Turn off electrical power to furnace.

3. Connect a manometer or appropriate gas pressure

gauge to the 1/8" NPT inlet pressure tap on the gas

valve.

4. Connect a second manometer or appropriate gas pres-

sure gauge to the 1/8" NPT outlet (manifold) pressure

tap on the gas valve.

5. Turn on gas supply to the furnace and verify inlet ma-

nometer connection is leak free before proceeding.

6. Set control board DIP switch #13 to “ON”

7. Jumper R to W1 on control board low volt terminal strip.

8. Turn on all gas appliances before starting furnace to

verify adequate supply pressure.

9. Turn on electrical power to the furnace. Observe and

record the gas supply pressure during ignition. If gas

supply pressure is not within the range shown above,

contact your gas supplier to correct the gas supply pres-

sure; do not make adjustments to the gas valve.

10. If gas supply pressure is within the acceptable range,

proceed with gas manifold pressure check.

NOTE:

Normal firing rate sequence is as follows for

DIP switch #13 in the “ON” position and 24 volts on

W1; a) Trial for ignition & flame stabilization period –

approximately 17 seconds at 80% rate. b) 35% rate for

approximately 2 minutes. c) 50% rate for 8 minutes.

11. Observe and record gas manifold pressure during the

50% firing rate. The gas manifold pressure at 50% fir-

ing rate must be within the appropriate range shown

below. If manifold pressure is found to be within the

acceptable range, do not adjust gas valve.

Natural Gas

Minimum .9" w.c.

Maximum 1.2" w.c.

L.P. Gas

Minimum 2.6" w.c.

Maximum 3.3" w.c.

Manifold Gas Pressure @ 50% Firing Rate

Manifold Gas Pressure

12. If manifold pressure is found to be lower than accept-

able (less than .9" wc for natural gas, less than 2.6"

WC for LP gas) turn the fine adjustment screw coun-

terclockwise slightly (¼ - ½ turn) and observe mani-

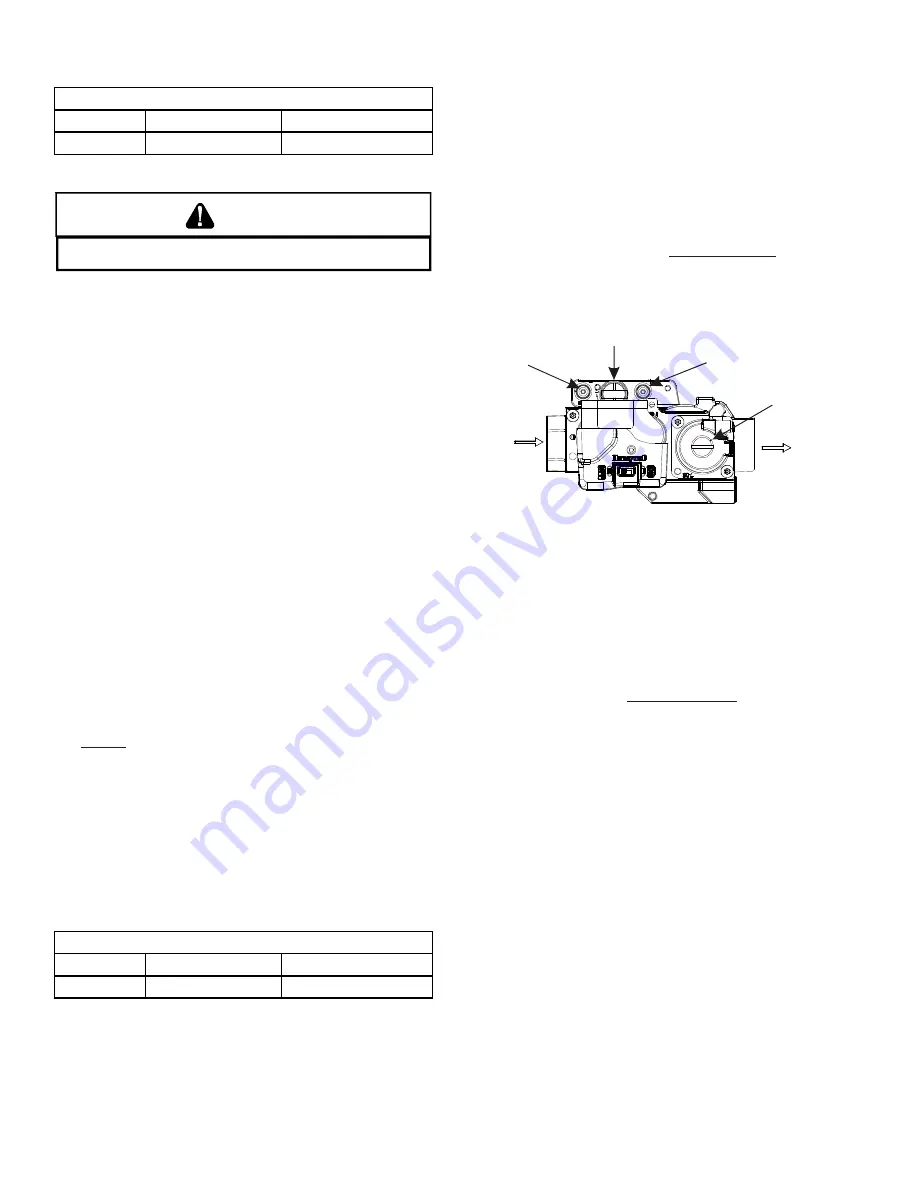

fold pressure. The fine adjustment screw is located

between the atmospheric and negative air ports and

extends from the base of the valve as shown in the

illustration below. Adjust in small increments using the

fine adjustment screw only, until manifold pressure is

within the acceptable range.

DO NOT ADJUST

the max

regulator screw located on top the gas valve.

DIRECTION

FLOW

Negative

Pressure Port

Gas Inlet

Atmospheric

Port

DO NOT

ADJUST

Follow procedure in this document

and

ADJUST HERE

13. If manifold pressure is found to be higher than accept-

able (more than 1.2" wc for natural gas, more than

3.3" WC for LP gas) turn the fine adjustment screw

clockwise slightly (¼ - ½ turn) and observe manifold

pressure. The fine adjustment screw is located between

the atmospheric and negative air ports and extends

from the base of the valve as shown in the illustration

below. Adjust in small increments using the fine ad-

justment screw only, until manifold pressure is within

the acceptable range.

DO NOT ADJUST

the max regu-

lator screw located on top the gas valve

S-304A CHECKING INDUCTOR COIL

Wired in series with ¾ and 1 HP ECM motors; the inductor

coil conditions the power supply to the motor, smoothing

out spikes and electrical noise. With voltage applied to

one side of the inductor coil, the output voltage to the

motor should be the same as incoming voltage.