76

SERVICING

When the control is powered up normally the light will be on

continuously. The display wil indicate

"ON"

when pow-

ered and in standby mode. This can be used to test for 120

volts and 24 volts to the control since both must be present

for the light to be on. If this step fails, check for 120 volts to

the control and check the transformer and its associated

wiring. If this step is successful give the control a call for

heat and wait five (5) seconds or until the furnace goes into

lockout. If the control detects a failure it will now be shown

on the diagnostic indicator light/display. Refer to the

Ab-

normal Operation

section in the

Sequence of Operation

sec-

tion of this manual for more detail on failure codes.

PCBKF103 / PCBKF104 / PCBKF105

1. Check for 120 volts from Line 1 (Hot) to Line 2 (Neutral)

at the ignition control. No voltage, check the door switch

connections and wire harness for continuity.

2. Check for 24 volts from W1 to C terminal on the ignition

control. No voltage. Check transformer, room thermo-

stat, and wiring.

If you have 24 volts coming off the transformer but re-

ceive approximately 13 volts on the terminal board be-

tween (C) and (R), check for blown fuse.

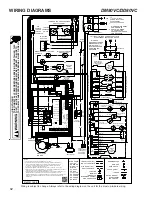

3. Check for 120 volts to the induced draft blower (low-

stage) by measuring voltage between Pin 3 and Pin 4

(on the 5-pin connector) located on circuit board. No

voltage, check for loose connection in the 5-pin con-

nector or replace ignition control.

Check for 120 volts to the induced draft blower (high-

stage) by measuring voltage between Pin 2 and Pin 4

(on the 5-pin connector) located on circuit board. No

voltage, check for loose connection in the 5-pin con-

nector, no call for high stage heat or replace ignition

control.

2

Y2

HUM

O

G

Y1

C

W1

R

DE

W2

1

4. If voltage is present in Steps 1 through 3 and the in-

duced draft blower is operating, check for 120 volts to

the ignitor during the preheat cycle. Measure voltage

between Pin 1 and Pin 5 (on the 5-pin connector) lo-

cated on ignition control. No voltage, check low stage

and high stage pressure switches or replace the igni-

tion control board.

5. After the ignitor warmup time, begin checking for 24

volts to the gas valve. Voltage will be present for seven

seconds only if proof of flame has been established.

6. If proof of flame was established voltage will be provided

to the air circulation blower following the heat on delay

period.

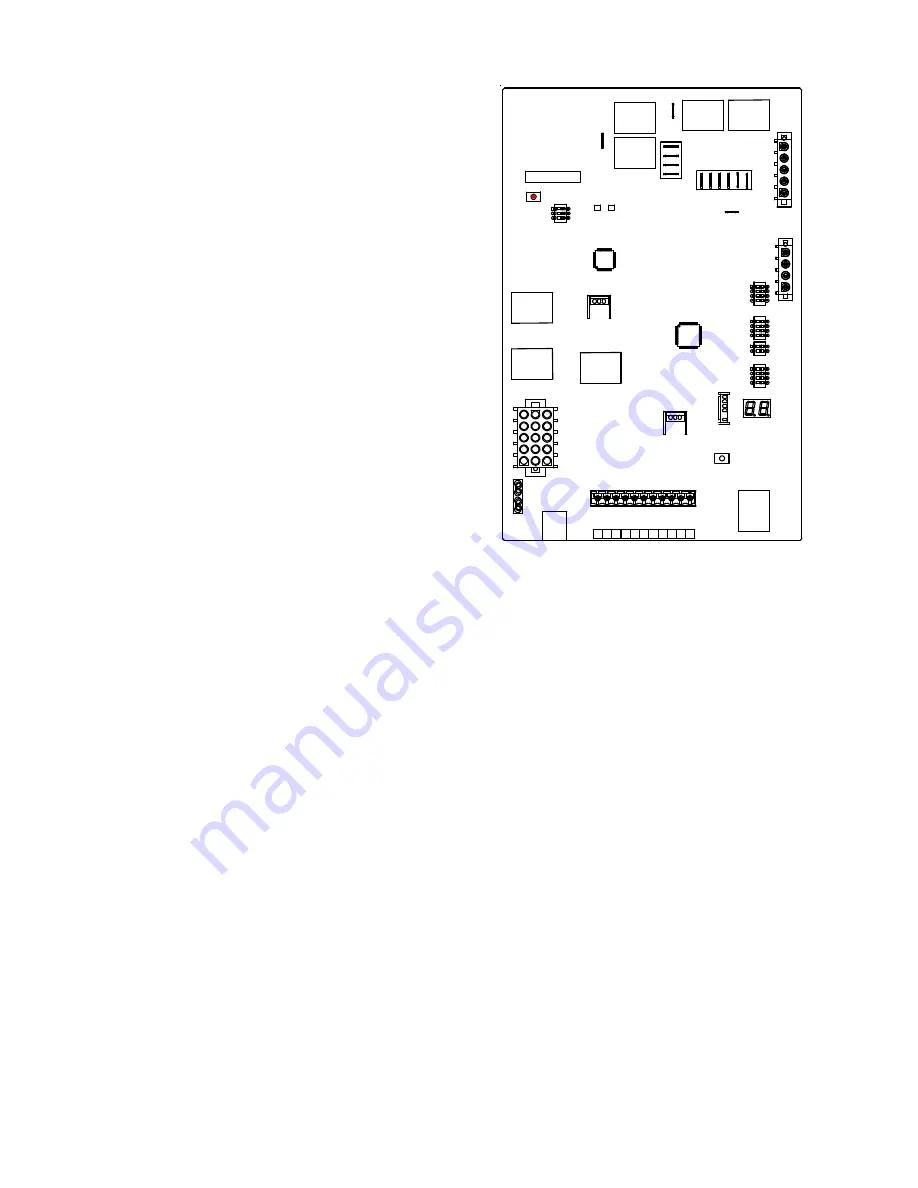

a. BEFORE replacing the ECM motor assembly or the

end bell, first check the motor with an Emerson

UltraCheck-EZ

TM

diaganostic tool . If the motor runs

with the diagnostic tool, the motor is good. To check

the end bell, see the previous variable speed testing

section of this manual before replacing the end bell.

b. The two-stage variable speed furnaces should have

120 Volts at the motor at all times, even without a

call for cooling or heating. These motors receive their

operational signals (5 Volts dc) through the 4-pin wir-

ing harness, connected between the motor and inte-

grated control board.

NOTE:

For complete trouble-

shooting information on units using the ECM blower

motors, refer to the

servicing section - Checking Air

Circulator Blowers

(S-16B)

in this service manual.