- 2 -

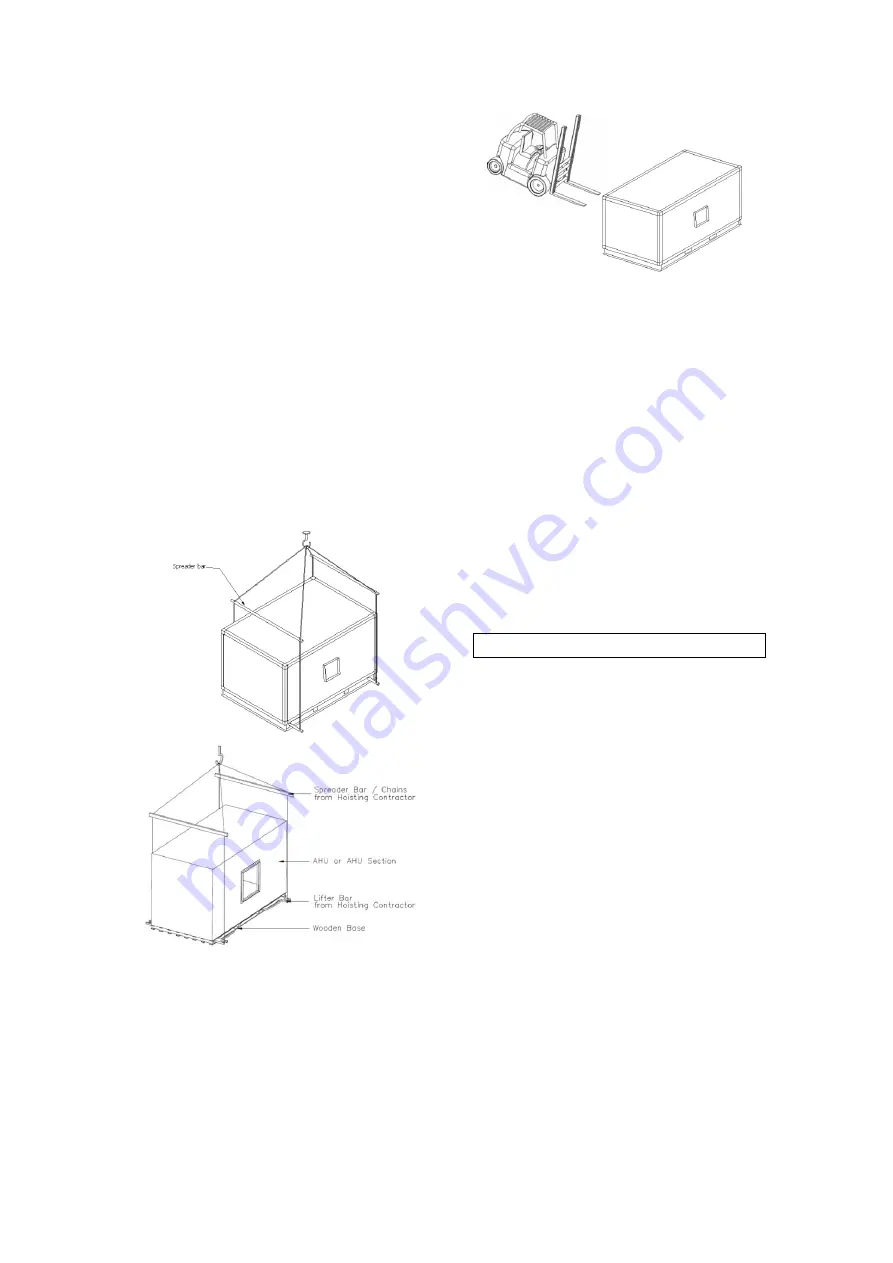

3. Handling / Rigging

Air handling units can be delivered as

separate section or completely assembled.

To prevent damage to unit cabinet, a

specific lifting method for offloading the

units is recommended as shown in Figure

1. The spreader bars must be in position

to prevent straps or cables from rubbing

the frame panel. Ensure stability and

balance when lifting the units and avoid

twisting or uneven lifting. Uneven lifting

may lead to accident or fatality which is

out of factory responsibility. Care should

be taken to prevent coil connections, drain

pan connection, damper operators and

accessory section from damage.

Do not push hard on the unit it self of on

the metal base. Use large wooden beam

to evenly distribute the force. Dropping

the units will result in permanently

damage of ball bearing, fan shaft or

loosen coil from the mounting.

AHU with metal base

AHU with wooden base

Figure 1 - Lifting method when offloading units

Transportation on the building site should

be done using forklift truck or a crane

(See Figure 2). The forks must only be

applied under the unit base frame and not

against the panel. In case when fork of

the forklift is too short then suitable

extensions should be used.

Figure 2 - Transportation by forklift truck

4. Storage

For external storage prior to installation,

the units must be protected from dust,

rain, constant sun exposure and rodents.

Although covered in shrink-wrapped

plastic sheeting, this is not intended for

long-term storage and should be remove

as soon as it is offloaded. Unit therefore

should be more protected by tarpaulins or

similar. Avoid exposed the units for coil

connection damages by transient load.

The fan impeller or motor drive must be

rotated once every month. Should the

units be stored for a period of exceeding 6

months, then it is recommended that the

drive belts be removed and store

separately.

IMPORTANT

INSTALLATION

AND

MAINTENANCE

ARE

TO

BE

PERFORMED ONLY BY QUALIFIED

AND EXPERIENCED PERSONNEL

WHO

ARE

FAMILIAR

WITH

NATIONAL AND LOCAL CODES

AND REGULATION.

5. Assembly and Installation

5.1 General

The system design and installation should

follow accepted industrial practice, such as

described in the ASHRAE Handbook.

These units are not designed to be

weatherproof (unless equipped with

canopy) and therefore should not be

installed outdoors. Flexible connections

should be used on the outlet and inlet

duct connections for all units. A minimal

amount of air leakage is normal on the

cabinet and it will not affect unit

performance. The air handling units are

not design to be suspended from the top

of the unit. Therefore, when the unit is

ceiling hung, make sure unit is supported

with a base rail of channel.