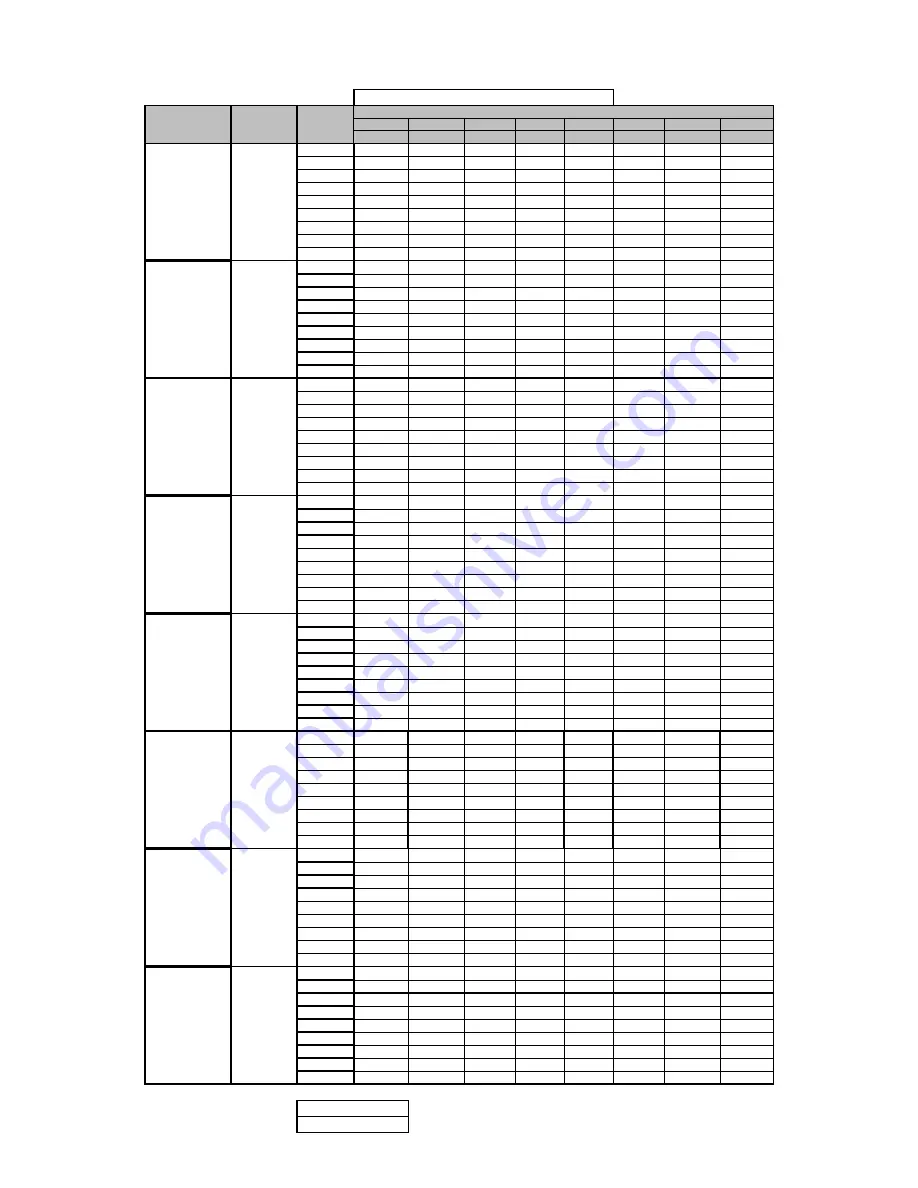

AIRFLOW TABLES

32

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

CFM

CFM

CFM

CFM

CFM

CFM

CFM

CFM

F01

658

585

545

495

444

390

332

151

F02

749

697

652

607

554

509

459

406

F03

925

881

840

800

760

721

681

645

F04

882

841

800

760

719

678

641

602

F05^

1330

1295

1273

1251

1223

1195

1168

1142

F06

1130

1090

1059

1022

991

957

926

895

F07

1158

1113

1090

1057

1024

996

964

935

F08

1270

1235

1208

1179

1147

1119

1088

1060

F09

1417

1380

1359

1336

1314

1288

1261

1238

F01

659

599

542

490

437

383

320

N/A

F02

1268

1221

1188

1154

1122

1091

1060

1029

F03

1087

1044

1008

973

938

905

871

841

F04

1118

1070

1033

997

963

929

896

865

F05^

1308

1262

1224

1197

1167

1141

1117

1089

F06

868

823

780

741

699

662

624

584

F07

922

877

835

795

757

718

679

642

F08

1382

1341

1311

1291

1263

1234

1206

1177

F09

1492

1448

1409

1381

1354

1332

1310

1288

F01

764

695

630

559

485

415

358

N/A

F02

1287

1235

1191

1147

1104

1062

1020

979

F03

1339

1301

1258

1217

1174

1131

1090

1048

F04

1396

1346

1298

1257

1217

1175

1135

1098

F05^

1185

1135

1088

1040

992

947

901

855

F06

1500

1460

1420

1360

1340

1294

1256

1219

F07

1591

1539

1493

1454

1416

1379

1347

1311

F08

1675

1622

1583

1545

1510

1474

1440

1402

F09

1790

1741

1701

1668

1631

1599

1567

1532

F01

710

646

580

515

432

367

314

274

F02

1298

1255

1216

1178

1140

1102

1067

1028

F03

1209

1166

1124

1083

1045

1005

964

923

F04

1138

1091

1045

1001

959

920

876

832

F05^

1391

1352

1314

1278

1241

1209

1175

1140

F06

977

931

880

836

785

734

683

626

F07

1036

985

940

895

848

799

751

705

F08

1456

1414

1376

1341

1302

1270

1238

1200

F09

1533

1488

1452

1415

1383

1350

1317

1286

F01

841

657

595

522

439

367

315

N/A

F02

1141

1089

1045

1001

958

914

869

823

F03

1311

1267

1226

1189

1150

1114

1072

1034

F04

1395

1347

1309

1270

1233

1199

1164

1125

F05^

1490

1447

1407

1373

1336

1303

1269

1237

F06

1553

1510

1469

1435

1401

1368

1335

1300

F07

1593

1548

1508

1474

1440

1409

1376

1343

F08

1776

1735

1695

1661

1628

1601

1570

1542

F09

1853

1812

1773

1739

1708

1679

1650

1623

F01

837

752

671

576

501

426

361

315

F02

1316

1270

1218

1166

1114

1061

1000

962

F03

1353

1323

1286

1235

1183

1131

1085

1040

F04

1587

1544

1506

1459

1416

1372

1323

1281

F05^

1731

1673

1632

1587

1546

1506

1463

1421

F06

1794

1744

1709

1671

1632

1591

1555

1513

F07

1861

1805

1761

1720

1681

1642

1603

1565

F08

1910

1873

1839

1798

1761

1723

1686

1648

F09

2110

2055

2035

2003

1973

1946

1907

1890

F01

802

724

637

551

468

389

342

294

F02

1405

1356

1308

1262

1210

1182

1155

1102

F03

1574

1531

1484

1440

1392

1357

1306

1256

F04

1619

1575

1526

1489

1446

1404

1355

1313

F05^

1688

1641

1600

1557

1513

1477

1428

1381

F06

1811

1769

1730

1686

1649

1610

1572

1525

F07

1857

1812

1774

1733

1697

1662

1622

1586

F08

1892

1850

1805

1774

1735

1692

1658

1621

F09

2116

2073

2039

2005

1981

1945

1909

1879

F01

851

774

692

615

535

470

411

359

F02

1677

1629

1583

1540

1498

1449

1399

1349

F03

1537

1489

1444

1404

1365

1322

1272

1211

F04

1416

1365

1315

1267

1220

1163

1106

1048

F05^

1154

1098

1043

983

932

874

819

755

F06

1806

1764

1729

1688

1654

1615

1578

1535

F07

1869

1816

1773

1731

1693

1661

1629

1589

F08

1947

1903

1865

1833

1802

1769

1743

1708

F09

2107

2066

2030

1996

1963

1932

1899

1867

HIGH STAGE COOLING AIRFLOW

DM80SN0803B*

DM80SN0804B*

DM80SN0805C*

Y2

DM80SN1005C*

Y2

TAP #

EXTERNAL STATIC PRESSURE, (INCHES WATER COLUMN)

DM80SN0403A*

DM80SN0603A*

DM80SN0604B*

Y2

Y2

Y2

Y2

Y2

MODEL

THERMOSTAT

CALL

DM80SN1205D*

Y2

NOTE:

^ Default Speed

DM80SN