SCHEDULED MAINTENANCE

26

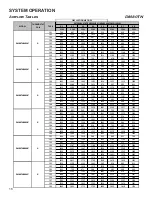

Upflow Models

Minimum Recommended Filter Size

*0403A*

1 - 16 X 25 Side or 1 - 14 X 24 Bottom Return

*0603A*

1 - 16 X 25 Side or 14 X 24 Bottom Return

*0603B*

1 - 16 X 25 Side or Bottom Return

*0803B*

1 - 16 X 25 Side or Bottom Return

*0804B*

1 - 16 X 25 Side or Bottom Return

*0804C*

1 - 16 X 25 Side or Bottom Return

*0805C*

1 - 16 X 25 Side or Bottom Return¹

*0805D*

2 - 16 X 25 Side or 1 - 20 X 25 Bottom Return¹

*1004C*

2 - 16 X 25 Side or 1 - 20 X 25 Bottom Return

*1005C*

2 - 16 X 25 Side or 1 - 20 X 25 Bottom Return

*1205D*

2 - 16 X 25 Side or 1 - 24 X 24 Bottom Return

Downflow Models

*0403A*

2 - 10 X 20 or 1 - 14 X 25 Top Return

*0603A*

2 - 10 X 20 or 1 - 14 X 25 Top Return

*0804B*

2 - 14 X 20 or 1 - 16 X 25 Top Return

*1005C*

2 - 14 X 20 or 1 - 20 X 25 Top Return

Larger filters may be used, filters may also be centrally located

¹ = Use 2 - 16 X 25 filters and two side returns or 20 X 25 filter on bottom

return if furnace is connected to a cooling unit over 4 tons nominal capacity

A combination of one side & bottom may be used instead of both sides

FLAME SENSOR (QUALIFIED SERVICER ONLY)

Under some conditions, the fuel or air supply can create a

nearly invisible coating on the flame sensor. This coating acts

as an insulator, causing a drop in the flame sensing signal. If

this occurs, a qualified servicer must carefully clean the flame

sensor with steel wool.

BURNERS

WARNING

H

I

GH

VOLTAGE

E

LECT

RI

CAL COM

P

ONENTS A

R

E CONTA

I

NE

D

I

N BOTH

COM

P

A

R

TMENTS.

T

O AVO

ID

ELECT

RI

CAL SHOCK,

I

N

J

U

R

Y O

R

D

EATH,

D

O NOT

R

EMOVE ANY

I

NTE

R

NAL COM

P

A

R

TMENT COVE

R

S

O

R

ATTEM

P

T ANY A

DJ

USTMENT.

C

ONTACT A QUAL

I

F

I

E

D

SE

R

V

I

CE AGENT AT ONCE

I

F AN ABNO

R

MAL FLAME

A

PP

EA

R

ANCE SHOUL

D

D

EVELO

P

.

Periodically during the heating season make a visual check of

the burner flames. Turn the furnace on at the thermostat. Wait

a few minutes since any dislodged dust will alter the normal

flame appearance. Flames should be stable, quiet, soft and

blue with slightly orange tips. They should not be yellow. They

should extend directly outward from the burner ports without

curling downward, floating or lifting off the ports.

Check the

Burner Flames for:

1. Stable, soft and blue.

2. Not curling, floating

or lifting off.

Burner Flame

HEATING PERFORMANCE TEST

Before attempting to diagnose an operating fault code, run

a Heating Performance Test to determine if the heating

system is performing within 5% of the BTU input found on

the rating plate of the unit being tested. To conduct a heating

performance test, the BTU input to the unit must be calculated

(see Clocking a Gas Meter). Before clocking a gas meter,

contact your local utility to provide the caloric value (BTU

content) of the natural gas in the area.

It is also important to confirm the airflow (CFM) is within the

temperature rise range (see Airflow Data in spec sheet) and

external static pressure range (approximately 0.5” water

column). How-to instructions can be found in the service

manual under Checking External Static Pressure and

Checking Temperature Rise.