38

1. Determine the tonnage of the cooling system installed

with the furnace. If the cooling capacity is in BTU/hr

divide it by 12,000 to convert capacity to TONs.

Example:

Cooling Capacity of 30,000 BTU/hr.

30,000/12,000 = 2.5 Tons

2. Determine the proper air flow for the cooling system.

Most cooling systems are designed to work with air

flows between 350 and 450 CFM per ton. Most manu-

facturers recommend an air flow of about 400 CFM

per ton.

Example:

2.5 tons X 400 CFM per ton = 1000 CFM

The cooling system manufacturer’s instructions must be checked

for required air flow. Any electronic air cleaners or other de-

vices may require specific air flows, consult installation instruc-

tions of those devices for requirements.

3. Knowing the furnace model, locate the high stage

cooling air flow charts in the Specification Sheet ap-

plicable to your model. Look up the cooling air flow

determined in step 2 and find the required cooling

speed and adjustment setting.

Example:

A DM97MC furnace installed with a 2.5

ton air conditioning system. The air flow needed is

1000 CFM. Looking at the cooling speed chart for

DM97MC, find the air flow closest to 1000 CFM. A

cooling airflow of 1000 CFM can be attained by select-

ing the cooling speed “C” and the adjustment to

“normal”.

4. Continuous fan speed is selectable at 25%, 50%, 75%

or 100% of the furnace’s maximum airflow capability.

Example:

If the furnace’s maximum airflow capabil-

ity is 2000 CFM, the continuous fan speed will be 0.25

x 2000 or 500 CFM.

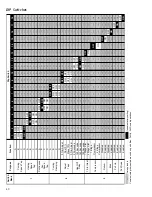

5. Locate the blower speed selection DIP switches on the

integrated control module. Select the desired “cool-

ing” speed tap by positioning switches 1 and 2 appro-

priately. Select the desired “adjust” tap by

positioning switches 9 and 10 appropriately. Refer to

the DIP switch chart for switch positions and their

corresponding taps. Verify CFM by noting the number

displayed on the dual 7-segment LED display.

6. The multi-speed circulator blower also offers several

custom ON/OFF ramping profiles. These profiles may

be used to enhance cooling performance and increase

comfort level. The ramping profiles are selected us-

ing DIP switches 7 and 8. Refer to the following fig-

ure for switch positions and their corresponding taps.

Refer to the bullet points below for a description of

each ramping profile. Verify CFM by noting the num-

ber displayed on the dual 7-segment LED display.

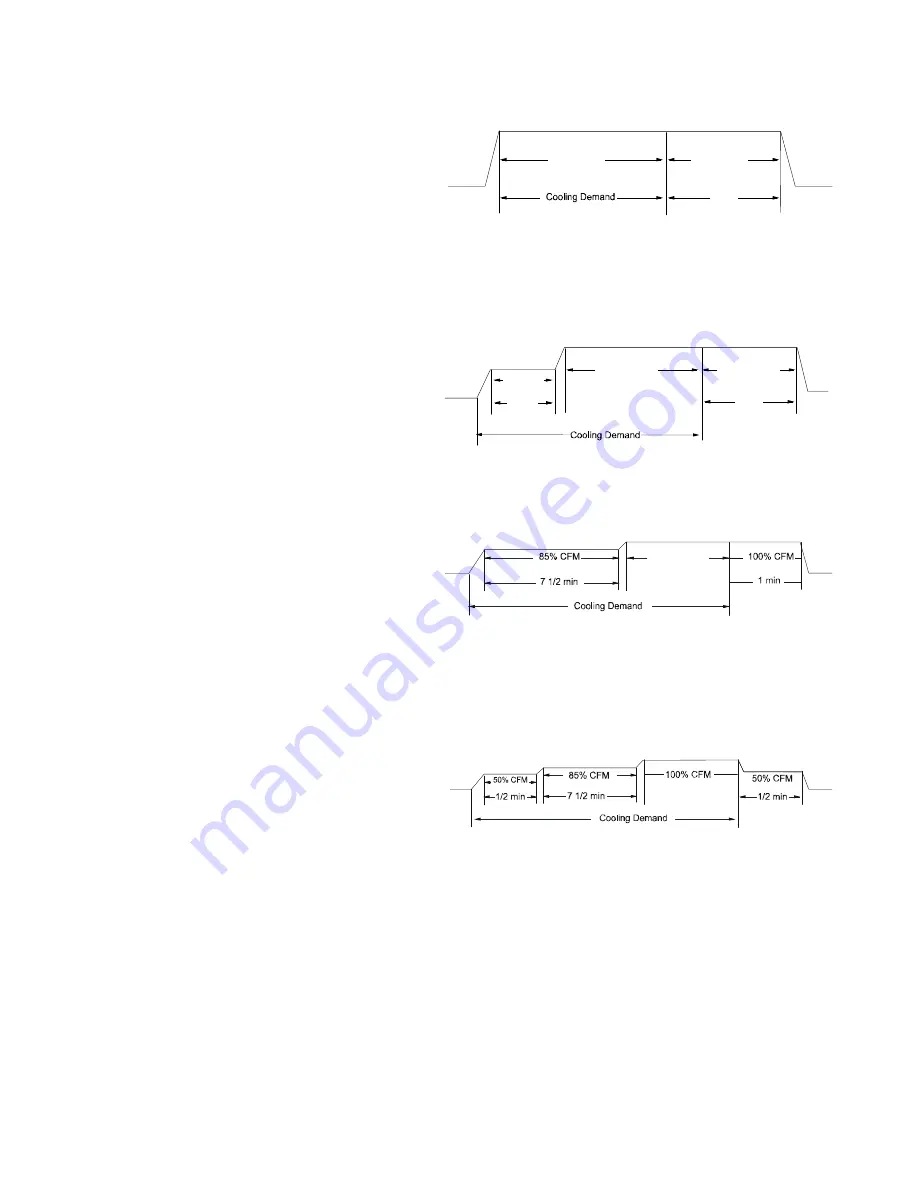

•

Profile A

provides only an OFF delay of one (1) minute at

100% of the cooling demand airflow.

OFF

100% CFM

100% CFM

1 min

OFF

•

Profile B

ramps up to full cooling demand airflow by first

stepping up to 50% of the full demand for 30 seconds. The

motor then ramps to 100% of the required airflow. A one

(1) minute OFF delay at 100% of the cooling airflow is pro-

vided.

50% CFM

1/2 min

100% CFM

100% CFM

1 min

OFF

OFF

•

Profile C

ramps up to 85% of the full cooling demand air-

flow and operates there for approximately 7 1/2 minutes.

The motor then steps up to the full demand airflow. Profile

C also has a one (1) minute 100% OFF delay.

100% CFM

OFF

OFF

•

Profile D

ramps up to 50% of the demand for 1/2 minute,

then ramps to 85% of the full cooling demand airflow and

operates there for approximately 7 1/2 minutes. The mo-

tor then steps up to the full demand airflow. Profile D has

a 1/2 minute at 50% airflow OFF delay.

OFF

OFF

7. Select the heating speed for your model from the heating

speed chart in the Specification Sheet. The “adjust” set-

ting (already established by the cooling speed selection)

determines which set of speeds are available. The selected

speed must provide a temperature rise within the rise range

listed with the particular model.

8. Select the desired “heating” speed tap by positioning

switches 3 and 4 appropriately. Refer to figure above.

Verify CFM by noting the number displayed on the dual 7-

segment LED display.

In general lower heating speeds will: reduce electrical consump-

tion, lower operating sound levels of the blower, and increase

the outlet air temperature delivered to the home. The speeds

available allow the blower performance to be optimized for the

particular homeowner’s needs.

OPERATION