39

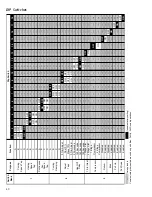

DIP S

WITCHES

There are 18 DIP switches on the modulating furnace IFC.

Switches are located in 3 rows, each having 6 switches.

Switches are numbered from 1 to 18. The “ON” position is

“UP’. The chart shows all 18 DIP switches, their function

and their factory position.

Switches 1 & 2

Select cooling speed A, B, C or D. Factory

setting is D (both switches up in the “ON” position. These

switches are ignored when using a CTK0* communicating

thermostat.

Switches 3 & 4

Select heating speed A, B, C or D. Factory

setting is B (3 ON, 4 OFF) These switches are ignored

when using a CTK0* communicating thermostat.

Switches 5 & 6

Select continuous fan speed A, B, C or D.

Factory setting is B (5 ON, 6 OFF) These selections are based

off of percentages of the maximum CFM that each model

furnace is rated for; A = 25%, B = 50%, C = 75%, D = 100%.

These switches are ignored when using a CTK0* communi-

cating thermostat.

Switches 7 & 8

Select cooling ramping profiles A, B, C or

D. Factory setting is A (both switches down in the “OFF”

position).Each ramping profile provides a different routine

for the indoor blower motor to follow in a call for cooling.

Rather than bringing the motor up to cooling speed imme-

diately, ramping profiles bring the motor up to cooling speed

in stages.

NOTE

:

Reductions in CFM for ramping are not added to re-

ductions in CFM for DEHUM. Example; CFM is reduced for

the fist several minutes of a cooling call by 15%, if a call for

DEHUM is present during this CFM reduction; CFM will not

be reduced by another 15%. Rather, after the ramping time

period has expired, the CFM would continue at the 15% re-

duction to satisfy the DEHUM request. These switches are

ignored when using a CTK0* communicating thermostat .

Switches 9 & 10

Select CFM Trim Adjustment. Choices

are 0%, + 10%, -10%. Factory setting is A. Trim adjustments

add or subtract from the CFM selections made by heat and

cool CFM selections. Trim adjustments affect cooling, and

heating fan speeds. These switches are ignored when using

a CTK0* communicating thermostat .

Switches 11 & 12

Select fan off delay in heat. Choices are

90, 120, 150, or 180 seconds. Factory setting is C, 150

seconds. These switches are ignored when using a CTK0*

communicating thermostat.

Switch 13

Selects thermostat type for heating. Factory

setting for this switch is OFF, this is the correct setting for

a conventional single stage stat or a CTK02**, CTK03 and

CTK04 communicating-modulating stats. To use a conven-

tional two stage heating thermostat or a CTK01 thermo-

stat, move this switch to the ON position.

Switch 14

Selects compressor setup for cooling. Factory

position is OFF. This is the correct position for a single

stage condensing unit. In this position, Y from the room

thermostat would connect to Y1 on the IFC. Full CFM se-

lected by switches 1 & 2 will be delivered during a Y1 call. If

using a two stage outdoor unit, move this switch to the ON

position and wire Y1 from the room stat to Y1 on the IFC,

wire Y2 on the room stat to Y2 on the IFC. This switch is

ignored when using a CTK0* communicating thermostat.

Switch 15

Selects DEHUM. Enabling this feature will re-

duce CFM in a call for cooling by 15%. Factory position is

OFF, in this position DEHUM is disabled. To use this fea-

ture the DIP switch must be turned to the ON position and a

normally closed dehumidistat be used. This switch is ig-

nored when using a CTK0* communicating thermostat.

Switches 16, 17, 1

8 These are system switches critical to

the ClimateTalk™ communicating network and must be left

in the factory enabled ON position.

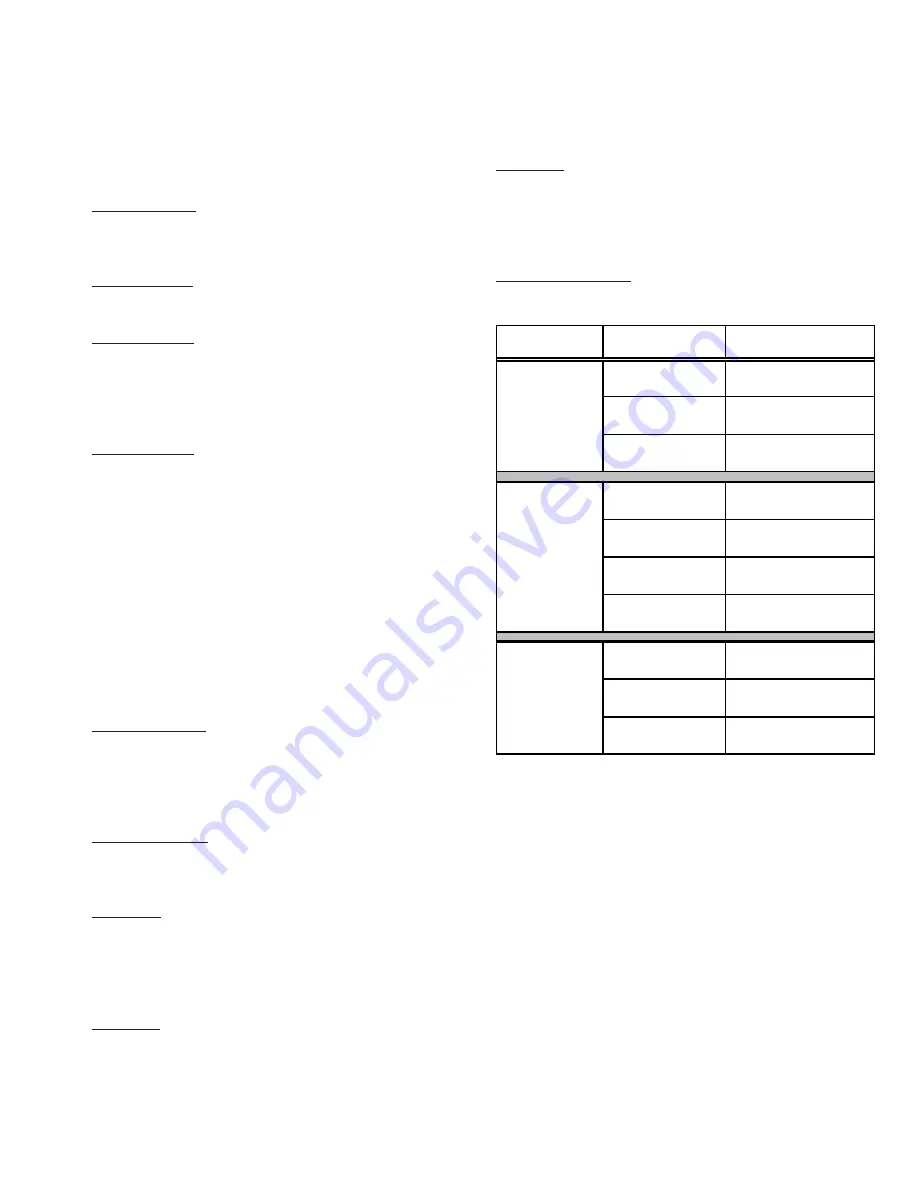

System

System Operating

Mode

Airflow Demand Source

Cooling

Air Conditioner

Heating

Furnace

Continuous Fan

Thermostat

Cooling

Heat Pump

Heat Pump Heating

Only

Heat Pump

Auxiliary Heating

Furnace

Continuous Fan

Thermostat

Cooling

Furnace

Heating

Furnace

Continuous Fan

Thermostat

F Non-

Comm 1stg Air

Conditioner

Air Conditioner +

Furnace

Heat Pump +

Furnace

For example, assume the system is an air conditioner

matched with a furnace. With a call for low stage cooling,

the air conditioner will calculate the system’s low stage cool-

ing airflow demand. The air conditioner will then send a

fan request along with the low stage cooling airflow de-

mand to the furnace. Once received, the furnace will send

the low stage cooling airflow demand to the ECM motor.

The ECM motor then delivers the low stage cooling airflow.

See the applicable ComfortNet air conditioner or heat pump

installation manual for the airflow delivered during cooling

or heat pump heating.

In continuous fan mode, the CTK0* thermostat provides the

airflow demand. The CTK02**, CTK03 and CTK04 thermo-

stats may be configured for one of threecontinuous fan speed

settings allow for 25%, 50% or 75% airflow, based on the

furnaces’ maximum airflow capability. During continuous

OPERATION