D–EIMWC00808-16HU - 18/64

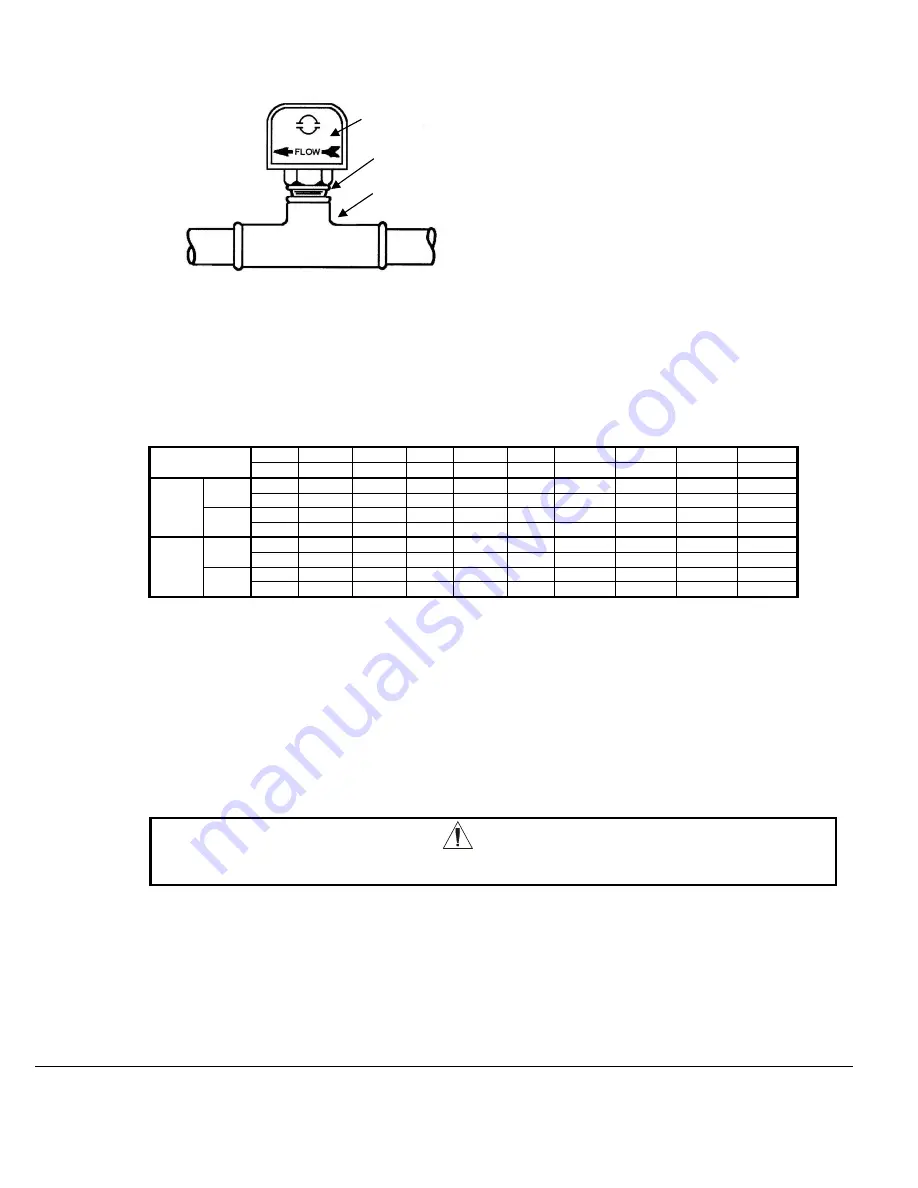

Figure 6, Flow Switch Mounting

If flow switches, by themselves, are being used, electrical connections in the Unit Control Panel must be made from the

common T3-S terminal to terminal CF for the condenser switch and T3-S to terminal EF for the evaporator switch. See

Figure 14, Field Wiring Diagram on page 34. The normally open contacts of the flow switch must be wired between

the terminals. Flow switch contact quality must be suitable for 24 VAC, low current (16ma). Flow switch wire must

be in separate conduit from any high voltage conductors (115 VAC and higher).

Table 1, Flow Switch Flow Rates

Pipe Size

(NOTE !)

inch

1 1/4

1 1/2

2

2 1/2

3

4

5

6

8

mm

32 (2)

38 (2)

51

63 (3)

76

102 (4)

127 (4)

153 (4)

204 (5)

Min.

Adjst.

Flow

gpm

5.8

7.5

13.7

18.0

27.5

65.0

125.0

190.0

205.0

Lpm

1.3

1.7

3.1

4.1

6.2

14.8

28.4

43.2

46.6

No

Flow

gpm

3.7

5.0

9.5

12.5

19.0

50.0

101.0

158.0

170.0

Lpm

0.8

1.1

2.2

2.8

4.3

11.4

22.9

35.9

38.6

Max.

Adjst.

Flow

gpm

13.3

19.2

29.0

34.5

53.0

128.0

245.0

375.0

415.0

Lpm

3.0

4.4

6.6

7.8

12.0

29.1

55.6

85.2

94.3

No

Flow

gpm

12.5

18.0

27.0

32.0

50.0

122.0

235.0

360.0

400.0

Lpm

2.8

4.1

6.1

7.3

11.4

27.7

53.4

81.8

90.8

NOTES:

1. A segmented 3-inch paddle (1, 2, and 3 inches) is furnished mounted, plus a 6-inch paddle loose.

2. Flow rates for a 2-inch paddle trimmed to fit the pipe.

3. Flow rates for a 3-inch paddle trimmed to fit the pipe.

4. Flow rates for a 3-inch paddle.

5. Flow rates for a 6-inch paddle

6. There is no data for pipe sizes above 8-inch. A switch minimum setting should provide protection against no flow

and close well before design flow is reached.

Alternatively, for a higher margin of protection, normally open auxiliary contacts in the pump starters can be wired in

series with the flow switches as shown in Figure 14, Field Wiring Diagram on page 34.

CAUTION

Freeze Notice: Neither the evaporator nor the condenser is self-draining;

both must be blown out to help avoid damage from freezing.

The piping should also include thermometers at the inlet and outlet connections and air vents at the high points.

The water heads can be interchanged (end for end) so that the water connections can be made at either end of the unit.

If this is done, new head gaskets must be used and control sensors relocated.

In cases where the water pump noise can be objectionable, vibration isolation sections are recommended at both the inlet

and outlet of the pump. In most cases, it will not be necessary to provide vibration eliminator sections in the condenser

inlet and outlet water lines. But they can be required where noise and vibration are critical.

Flow direction marked

on switch

I in. (25mm) NPT flow

switch connection

Tee