D–EIMWC00808-16HU - 44/64

The oil coolers maintain the proper oil temperature under normal operating conditions. The coolant flow control

valve maintains 95°F to 105°F (35°C to 41°C). Lubrication protection for coast down in the event of a power failure

is accomplished by a spring-loaded piston in models CE050 through 100. When the oil pump is started, the piston is

forced back against the spring by the oil pressure, compressing the spring, and filling the piston cavity with oil. When

the pump stops, the spring pressure on the piston forces the oil back out to the bearings.

In model CE126 the compressor coast down lubrication is supplied from a gravity feed oil reservoir.

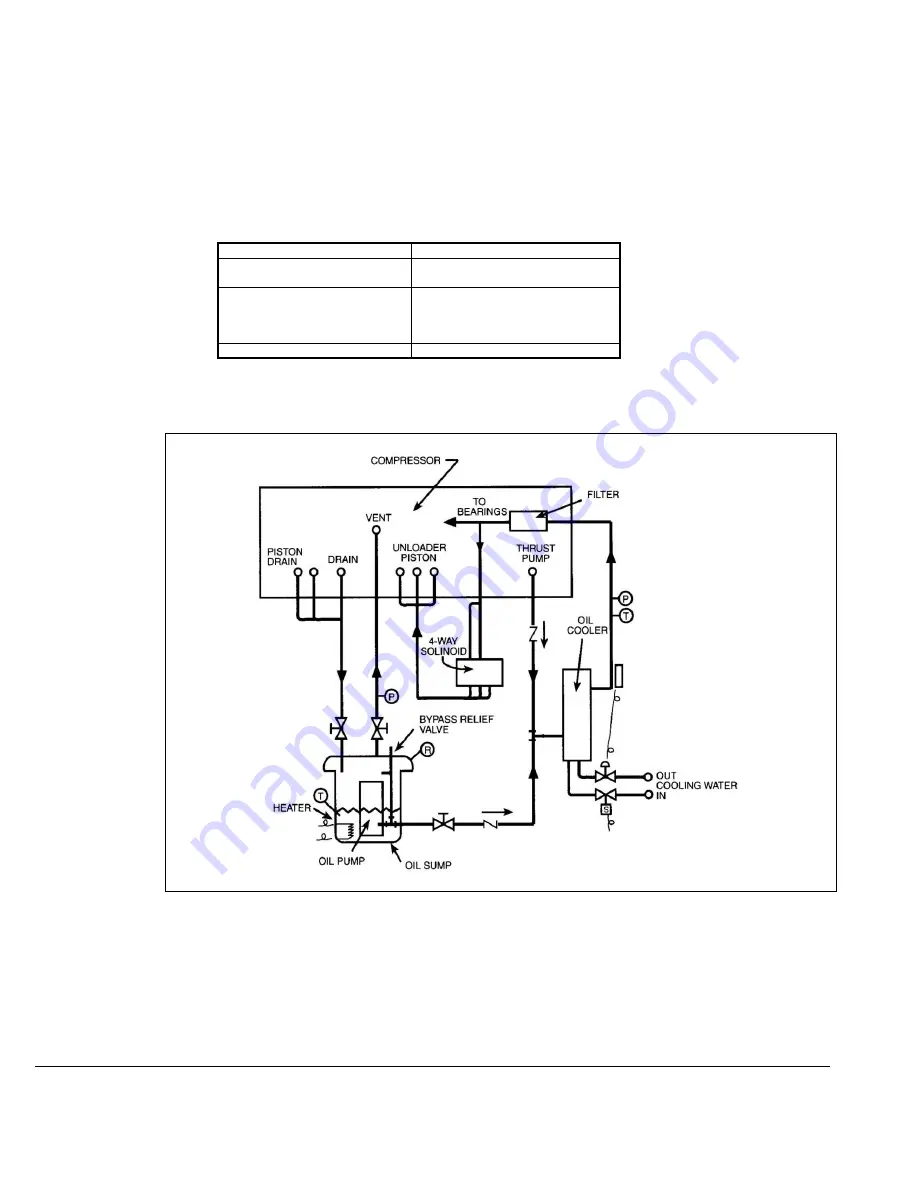

A typical flow diagram is shown in Figure 23.

Table 13, Approved Polyolester Oils For R-134a Units

Compressor Models

CE050 - 126

Lubricant Designation

Mobil Artic EAL 46;

ICI Emkarate RL32H

(2)

Daikin Part Number

55 Gal. Drum

5 Gal. Drum

1 Gal. Can

735030432, Rev 47

735030433, Rev 47

735030435, Rev 47

Compressor Oil Label

070200106, Rev OB

NOTES

:

1. Approved oil from two suppliers can be mixed, although they have slightly different viscosity.

2. Lubricant from either supplier can be furnished when ordering by Daikin part number.

Figure 23, Typical Oil Flow Diagram

NOTES:

1.

Diagram does not apply to CE 050 compressors, which have self-contained lubrication systems.

2.

Connections are not necessarily in correct relative location.

3.

R = relief valve, P = pressure sensor, T = temperature sensor, S = solenoid valve

Hot Gas Bypass

All units can be equipped with an optional hot gas bypass system that feeds discharge gas directly into the evaporator

when the system load falls below 10% compressor capacity.