D–EIMWC00808-16HU - 41/64

Capacity Control System

The opening or closing of the inlet vanes controls the quantity of refrigerant entering the impeller thereby controlling

the compressor capacity. The vane movement occurs in response to oil flow from the SA or SB 4-way solenoid valves,

which in turn, respond to instructions from the unit microprocessor as it senses leaving chilled water temperature. This

oil flow activates a sliding piston that rotates the vanes.

Vane Operation

The hydraulic system for the inlet guide vane capacity control operation consists of a 4-way normally open solenoid

valve located in the oil management control panel or on the compressor close to the suction connection. Oil under

pressure from the oil filter is directed by the 4-way valve to either or both sides of the piston, depending on whether the

control signal is to load, unload, or hold.

To open the vanes (loading compressor), solenoid SA is de-energized and SB is energized, allowing oil flow from port

SA to one side of the piston. The other side drains through port SB.

To close the vanes (unload compressor), valve SB is de-energized and valve SA is energized to move the piston and

vanes toward the unload position.

When both solenoid valves SA and SB are de-energized, full oil pressure is directed to both sides of the piston through

ports SA and SB, and the vanes are held in that position. Refer to Figure 21 and Figure 22 for solenoid action. Note

that both solenoids cannot be

energized

simultaneously.

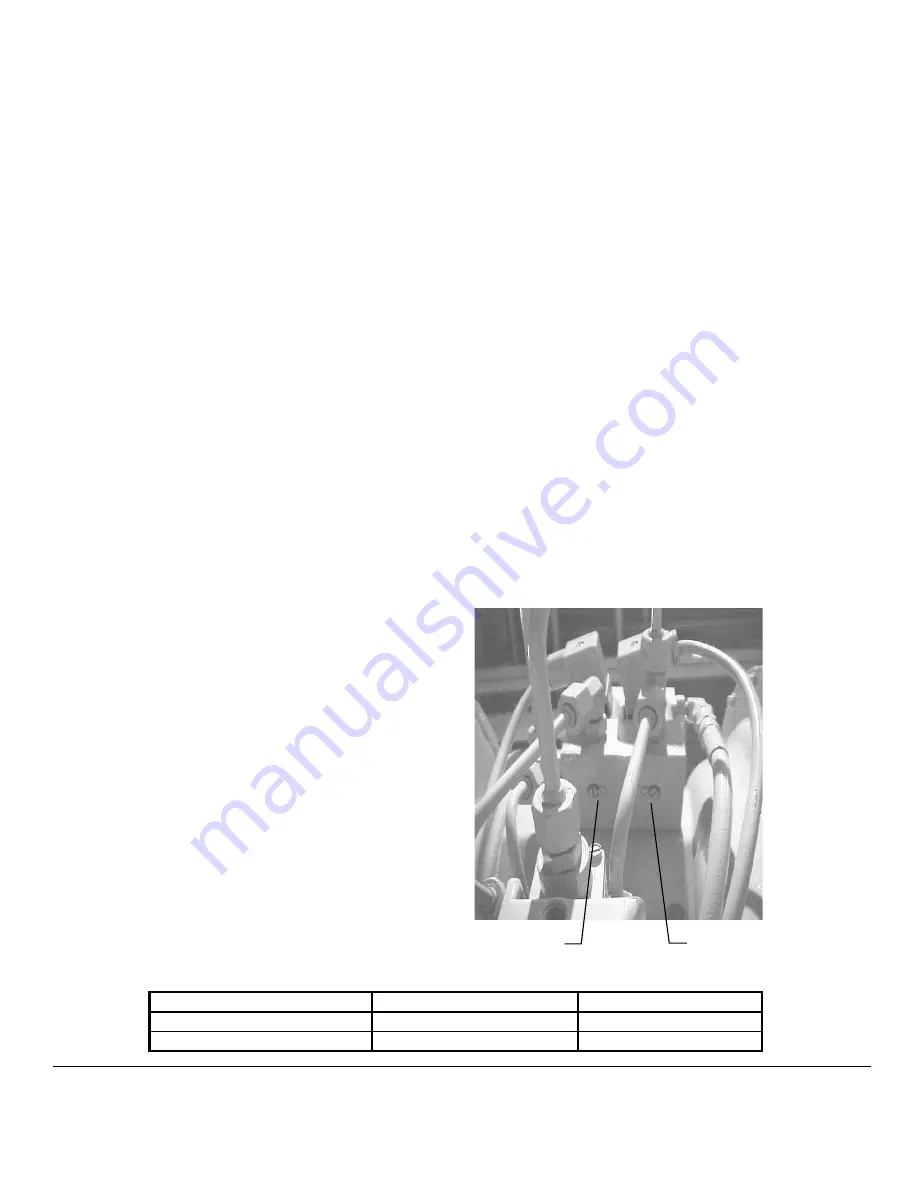

Vane Speed Metering Valves

The speed at which the capacity control vanes are opened or closed can be adjusted to suit system operating requirements.

Adjustable needle valves in the oil drain lines are used to control the rate of bleed-off and consequently the “vane speed”.

These needle valves are part of the 4-way solenoid valve assembly located in the compressor lube box (Figure 20).

The valves are normally factory set so that the vanes will move from fully closed to fully opened in the time periods

shown in Table 12 on page 41.

Figure 19, Needle Valve Location

The speed must be slow enough to prevent over-

controlling and hunting.

The left adjusting screw is the SB needle valve for

adjusting the vane OPENING speed for loading the

compressor. Turn this screw clockwise to decrease the

vane opening speed and counterclockwise to increase

the opening speed.

The right adjusting screw is the SA needle valve for

adjusting the CLOSING speed to unload the

compressor. The same adjustment method applies;

clockwise to decrease closing, counterclockwise to

increase vane closing.

These adjustments are sensitive. Turn the adjusting

screws a few degrees at a time.

The vane speed is factory set and varies by compressor

size.

The start-up technician may readjust the vane speed at

initial start-up to meet job conditions.

Table 12, Vane Speed Factory Setting

Compressor Model

Opening Time

Closing Time

CE079 - CE100

3 - 5 min.

1 - 2 min

CE126

5 - 8 min.

1 - 2 min.

Open (Load)

Close (Unload)