SERVICING

33

NOTE

: The Flushing Method using R-11 refrigerant is no

longer approved by Daikin Brand Heating-Cooling.

S-120 REFRIGERANT PIPING

The piping of a refrigeration system is very important in relation

to system capacity, proper oil return to compressor, pumping

rate of compressor and cooling performance of the evaporator.

A bi-flow filter drier must be brazed on by the installer onsite.

Ensure the bi-flow filter drier pain finish is intact after brazing.

If the paint of the steel filter drier has been burned or chipped,

repaint or treat with a rust preventative. The recommended lo-

cation of the filter drier is before the expansion device at the

indoor unit. The liquid line must be insulated if more than 50

feet of liquid line will pass through an area that may reach tem-

peratures of 30° of higher than ambient in cooling mode.

FVC oils maintain a consistent viscosity over a large tempera-

ture range which aids in the oil return to the compressor; how-

ever, there will be some installations which require oil return

traps. These installations should be avoided whenever possi-

ble, as adding oil traps to the refrigerant lines also increases

the opportunity for debris and moisture to be introduced into

the system. Avoid long running traps in horizontal suction line.

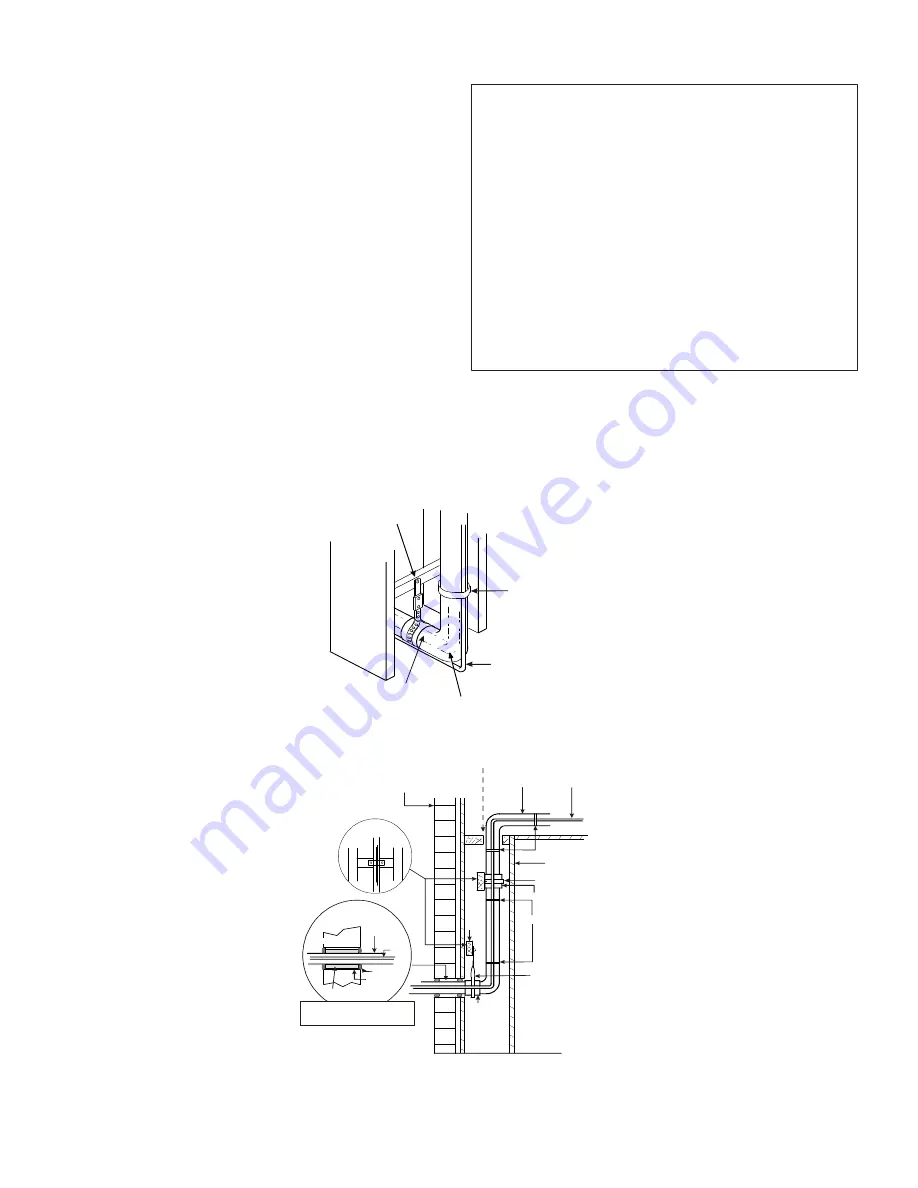

Liquid Line

Suction Line

Wrapped in Armaflex

®

Metal

Sleeve

Hanger

Wall

Stud

Liquid Line

Strapped to

Suction Line

Figure 1-1.

Installa

�on

o

f Refrigera

�on

Piping Fr

o

m Ver

�

cal t

o

H

o

riz

o

ntal

Outside Wall

Inside Wall

Liquid Line

Suction Line

IMPORTANT

- Refrigerant lines must not touch wall.

Strap

Sleeve

Strap

Sleeve

Wire Tie

Wire Tie

PVC Pipe

Caulk

Outside Wall

Armaflex

Wrapped

Suction Line

®

Liquid

Line

Wood Block

Between Studs

I

MPORTANT:

Refrigerant lines must NOT

come into contact with structure.

Fiberglass Insulation

Wood

Block

Figure 1-2. Installa

�on

of

Refrigerant Piping (Ver

�

cal)

New constru

cti

on shown

NOTE:

If line set is installed

on

the exter

io

r

of

an

ou

tside wall, similar installa

�on

prac

�

ces are t

o

be used.

IMPORTANT

To avoid overhea

�

ng the service valve, TXV, sensor, or

fi

lter

drier while brazing, wrap the component with a wet rag, or

use a thermal heat trap compound. Be sure to follow the

manufacturer’s instruc

�

on when using the heat trap

compound. Note: Remove Schrader valves from service

valves before brazing tubes to the valves. Use a brazing alloy

of 2% minimum silver content. Do not use

fl

ux.

Torch heat required to braze tubes of various sizes is

propor

�

onal to the size of the tube. Tubes of smaller size

require less heat to bring the tube to brazing temperature

before adding brazing alloy. Applying too much heat to any

tube can melt the tube. Service personnel must use the

appropriate heat level for the size of the tube being brazed.