TROUBLESHOOTING

17

A

VOID

CONTACT

WITH

THE

CHARGED

AREA

.

•N

EVER

TOUCH

THE

CHARGED

AREA

BEFORE

CONFIRMING

THAT

THE

RESIDUAL

VOLTAGE

IS

50

VOLTS

OR

LESS

.

1. S

HUT

DOWN

THE

POWER

AND

LEAVE

THE

CONTROL

BOX

FOR

10

MINUTES

.

2. M

AKE

SURE

TO

TOUCH

THE

E

ARTH

GROUND

TERMINAL

TO

RELEASE

THE

STATIC

ELECTRICITY

FROM

YOUR

BODY

(

TO

PREVENT

FAILURE

OF

THE

PC

BOARD

).

3. M

EASURE

THE

RESIDUAL

VOLTAGE

IN

THE

SPECIFIED

MEASUREMENT

POSITION

USING

A

VOM

WHILE

PAYING

ATTENTION

NOT

TO

TOUCH

THE

CHARGED

AREA

.

4. I

MMEDIATELY

AFTER

MEASURING

THE

RESIDUAL

VOLTAGE

,

DISCONNECT

THE

CONNECTORS

OF

THE

OUTDOOR

UNIT

’

S

FAN

MOTOR

. (I

F

THE

FAN

BLADE

ROTATES

BY

STRONG

WIND

BLOWING

AGAINST

IT

,

THE

CAPACITOR

WILL BE CHARGED,

CAUSING

THE

DANGER

OF

ELECTRICAL

SHOCK

.)

WARNING

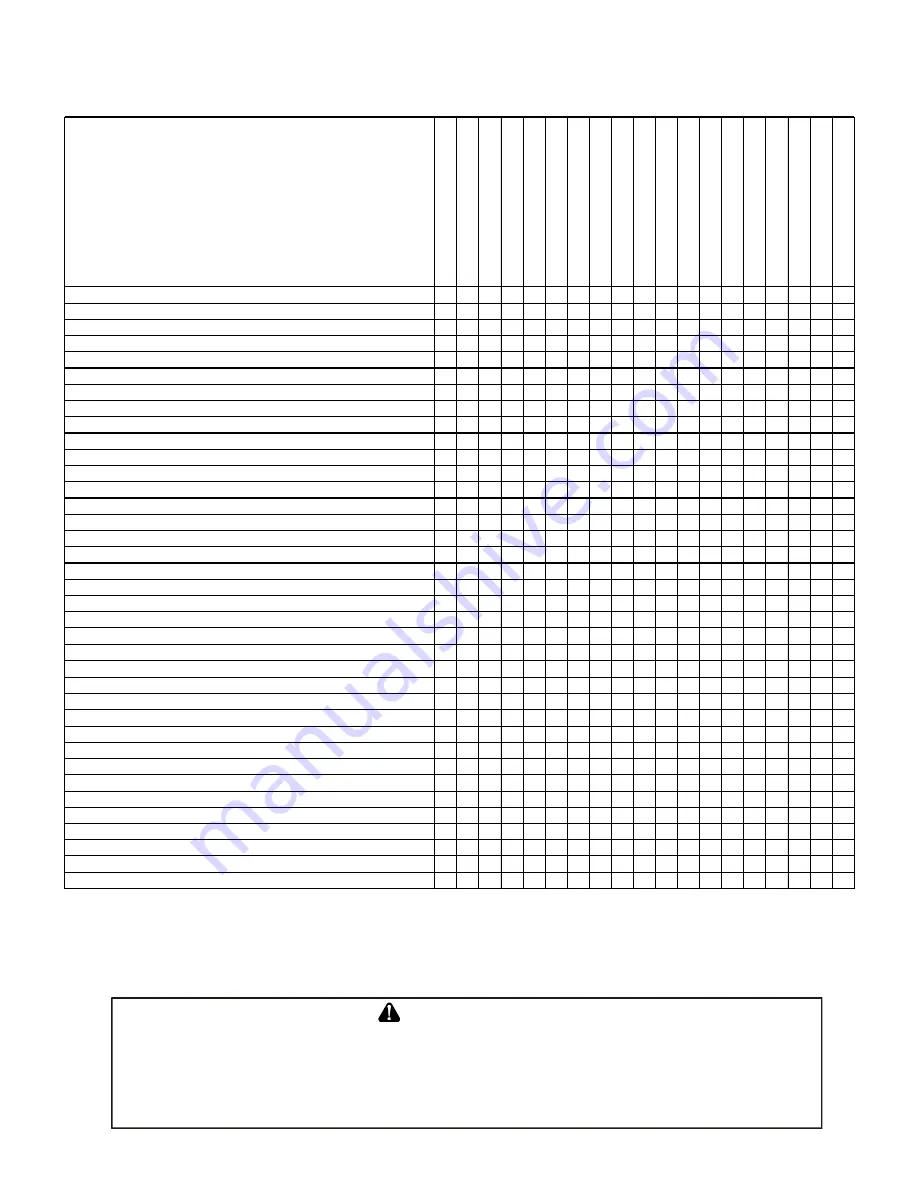

Outdoor Normal Temperature Opera

�n

g

Ran

ge: 67-115°F /

Indoo

r Normal Temperature Opera

�n

g

Ran

ge: 65 - 85°F

POSSIBLE CAUSE

X IN ANALYSIS GUIDE INDICATE

"POSSIBLE CAUSE"

C

om

p

di

sc

ha

rg

e t

em

p

>

20

0F

C

om

p

di

sc

ha

rg

e t

em

p

<

10

5F

Co

m

p

di

sc

ha

rg

e

SH

>

7

0F

Co

m

p

di

sc

ha

rg

e

SH

<

2

0F

H

igh

p

re

ss

ur

e

>

490

ps

i

H

igh

p

re

ss

ur

e

<

255

ps

i

LSV

S

C

>

1

2F

LSV

S

C

<

4

F

O

D

SSV

S

H

>

20

F

O

D

SSV

S

H

<

4

F

Lo

w

p

re

ss

ur

e

>

185

ps

i

Lo

w

p

re

ss

ur

e

<

100

ps

i

R

equ

es

te

d

%

de

m

an

d

<

A

ct

ua

l

R

equ

es

te

d

%

de

m

an

d

>

A

ct

ua

l

R

epe

at

ed

s

to

p/

st

ar

t

W

ea

k

coo

lin

g

N

o

sw

itc

h

co

oli

ng

No

is

e

S

top

op

er

at

io

n

Liquid stop valve does not fully open

X

X

X

X

X

X

X X X

X

Gas stop valve does not fully open

X

X

X

X

X

X

Line set restriction

X

X

X

X

X

X

X X X

X

Line set length is too long

X

X

X X

X

Blocked filter-dryer

X

X

X

X

X

X

X X X

X

ID EEV coil failure

X X X X X X X X X X X X X X X X

X

ID EEV failure

X X X X X X X X X X X X X X X X

Check valve failure – Blocked

X

X

X

X X

X

X X X

High Pressure switch failure

X

Pressure sensor failure

X

X

X

X

X

X

X

Discharge temp sensor failure

X

X

X

X

X

X

X

X

X

Coil temp sensor failure

X

X

X

X

X

X

X

X

Liquid temp sensor failure

Ambient temp sensor failure

X

X

X

X

X

X

X

OD recirculation

X

X

X

X

X

X

X

ID recirculation

X

X

X

X

X

X

X

X

Dirty OD Heat-exchanger

X

X

X

X

X

X

X

Dirty ID Heat-exchanger

X

X

X

X

X X X X X

Outdoor Ambient temp is too high

X

X

X

X

X X X

X

Outdoor Ambient temp is too low

X

X

X X

X X X X X

ID suction temp is too high

X

X

ID suction temp is too low

X

X

X

X

X X X X X

Mixture of non-condensible gas

X

X

X

X X

X

X X X

X

OD fan motor failure

X

X

X

X

X

X

X

X

X

Over charge

X X X X X

X

X

X

X

X

Under charge

X X X

X

X X

X

X

X

Leak

X X X

X

X X

X

X X X

X

TXV failure

X X X X X X X X X X X X X X X X

TXV is small

X

X

X

X

X

X

X

TXV is big

X

X

X

X

X X

X

X

OD Control Board Failure

X

ID Failure

X X X X X X X X X X X X X X X X X

X

Compressor failure

X X X

X

X

X X X

X X

Cooling loop is not attached

X X X

Cooling loop grease is not enough

X X X

Compressor and Gas furnace are operating at the same time

X

Low ID CFM

X

X

X

X

X

X

X

X

X

COOLING ANALYSIS CHART