SERVICING

36

S-4 CHECKING TRANSFORMER AND CONTROL CIRCUIT

HIGH VOLTAGE !

D

ISCONNECT

ALL

POWER

BEFORE

SERVICING

OR

INSTALLING

. M

ULTIPLE

POWER

SOURCES

MAY

BE

PRESENT

. F

AILURE

TO

DO

SO

MAY

CAUSE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

.

WARNING

A step-down transformer (208/230 volt primary to 24 volt second-

ary) is provided with each indoor unit. This allows ample capac-

ity for use with resistance heaters. The outdoor sections do not

contain a transformer (see indoor unit WIRING DIAGRAM).

D

ISCONNECT

ALL

POWER

BEFORE

SERVICING

.

WARNING

1. Remove control panel cover, or etc., to gain access to trans-

former.

With power ON:

L

INE

V

OLTAGE

NOW

PRESENT

.

WARNING

2. Using a voltmeter, check voltage across secondary voltage

side of transformer (R to C).

3. No voltage indicates faulty transformer, bad wiring, or bad

splices.

4. Check transformer primary voltage at incoming line voltage

connections and/or splices.

5 If line voltage available at primary voltage side of transformer

and wiring and splices good, transformer is inoperative. Re-

place.

S-12 CHECKING HIGH PRESSURE CONTROL SWITCH

HIGH VOLTAGE !

D

ISCONNECT

ALL

POWER

BEFORE

SERVICING

OR

INSTALLING

. M

ULTIPLE

POWER

SOURCES

MAY

BE

PRESENT

. F

AILURE

TO

DO

SO

MAY

CAUSE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

.

WARNING

The high pressure control switch senses the pressure in the com-

pressor discharge line. If abnormally high condensing pressures

develop, the contacts of the control open, breaking the control

circuit before the compressor motor overloads. This control is

automatically reset.

1. Using an ohmmeter, check across terminals of high pressure

control, with wire removed. If not continuous, the contacts

are open.

2. Attach a gauge to the dill valve port on the base valve.

With power ON:

L

INE

V

OLTAGE

NOW

PRESENT

.

WARNING

3. Start the system in charge mode and place a piece of card-

board in front of the outdoor coil, raising the condensing

pressure.

4. Check pressure at which the high pressure control cuts-out.

If it cuts-out at 605 PSIG to -17 PSIG, it is operating normally

(See causes for high head pressure in Cooling/Heating Analy-

sis Chart). If it cuts out below this pressure range, replace the

control.

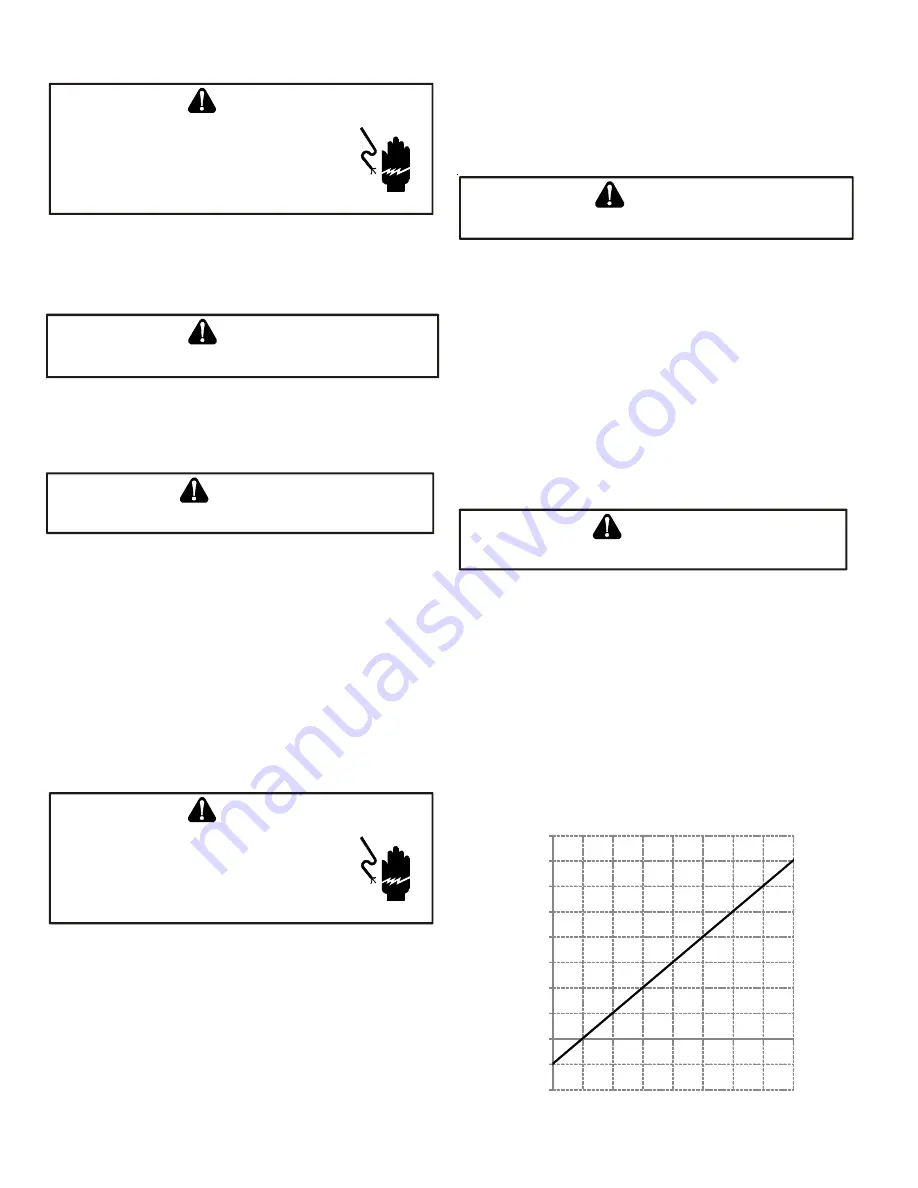

S-13 CHECKING INDOOR AND OUTDOOR HI/LOW PRES-

SURE SENSOR

With Power ON:

L

INE

V

OLTAGE

NOW

PRESENT

.

WARNING

1. Connect a bar gauge manifold to the heat pump unit

2. Connect a pair of extended Molex probe tips to your voltmeter

test leads.

3. Find the suction pressure in the cool mode, or discharge

pressure in the heat mode. (bar gauge manifold) Connect a

DC voltmeter across sensor terminals 1 and 3, (black and

white wires) and record the DC voltage.

4. Compare your readings to the detected pressure vs output

voltage in the following table. Replace the sensor if the sensor

is open, shorted, or outside of the voltage range.

-200

-100

0

100

200

300

400

500

600

700

800

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

De

te

ct

ed

P

ress

u

re

(P

SIG

)

Output Voltage (DCV)