68

PIM00504

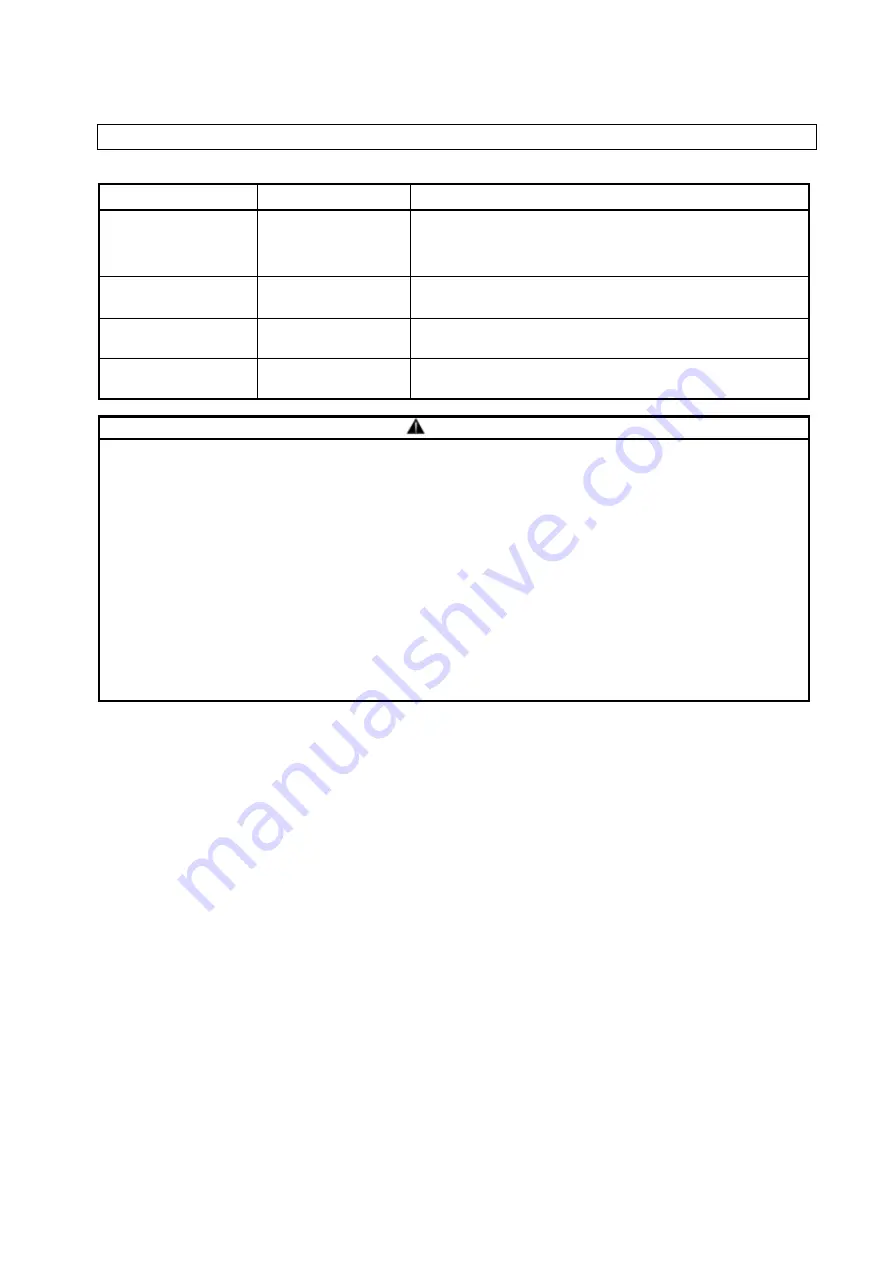

13.4 Cleaning/Replacement Work

Inspection

L

ti

/It

Work Timing/Interval

Work Instructions

•

Oil tank/

Replacing the oil

Once a year

Replace the hydraulic oil at regular intervals. Use for a

long time without replacing the oil will adversely affect the

operation and life of the hydraulic equipment.

•

Oil cooler

•

Cleaning the core

Once a year

Disassemble and clean according to “13.5 Oil Cooler

Maintenance Instructions”.

•

Oil filler port cum

air breather

Once a year

Disassemble and clean according to “13.6 Oil Filler Port

Cum Air Breather Maintenance Instructions”.

•

Suction strainer

Once a year

Disassemble and clean according to “13.7 Suction

Strainer Maintenance Instructions”.

DANGER

Do not get close to or come into contact with rotating parts.

When touching the interior of the controller, abide by the following procedure to prevent

electric shocks.

i)

Shut off the source power supply to the hydraulic unit. (Set the power supply circuit

breaker of the circuit that is supplying the power to “OFF”.)

Hang a tag stating, for example, “Operation Prohibited (Work in Progress)” on the power

supply circuit breaker or other device, preventing erroneous operation while the work is

in progress.

ii) Wait at least 5 minutes before removing the cover, etc. from the controller. A capacitor

with a large capacity is used inside the controller, and working while the capacitor is

charged poses a risk of electric shock and other hazards. Always wait at least 5 minutes

(the time required to discharge the electric charge in the capacitor) before removing the

cover.

When running the unit, mount all the covers on the controller before turning the power on.