Installation manual

17

E(D/B)(H/L)Q011~016BB

Unit for air to water heat pump system

4PW67904-1 – 01.2011

General precautions concerning water circuit

Before continuing the installation of the unit, check the following

points:

■

the maximum water pressure is 4 bar,

■

the maximum water temperature during space heating is 65°C

(safety device setting) and 75°C

(1)

during domestic hot water

operation (safety device setting). Make sure that the installed

piping and piping accessories (e.g., valve, connections, ...) can

withstand the temperatures as shown in the figure below.

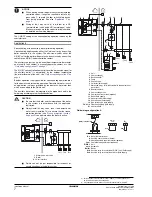

1 Unit

2 Heat exchanger

3 Backup heater

(2)

4 Pump

5 Shut-off valve

6 Motorised 3-way valve (delivered with domestic hot water

tank)

7 Motorised 2-way valve (field supply)

8 Collector (field supply)

9 Domestic hot water tank (optional)

10 Booster heater

(3)

11 Heat exchanger coil

FCU1...3 Fan coil unit (optional)

FHL1...3 Floor heating loop

T Room thermostat (optional)

■

Provide adequate safeguards in the water circuit to be sure that

the water pressure will never exceed the maximum allowable

working pressure (4 bar).

■

Drain taps must be provided at all low points of the system to

permit complete drainage of the circuit during maintenance.

A drain valve is provided in the unit to drain the water from the

unit water system.

■

Make sure to provide a proper drain for the pressure relief valve

to avoid any water coming into contact with electrical parts.

■

Air vents must be provided at all high points of the system. The

vents should be located at points which are easily accessible for

servicing. An automatic air purge is provided inside the unit.

Check that this air purge valve is not tightened too much so that

automatic release of air in the water circuit remains possible.

■

Take care that the components installed in the field piping can

withstand the water pressure and water temperature.

■

Always use materials which are compatible with water used in

the system and with the materials used in the unit.

If air, moisture or dust gets in the water circuit, problems may occur.

Therefore, always take into account the following when connecting

the water circuit:

■

use clean pipes only,

■

hold the pipe end downwards when removing burrs,

■

cover the pipe end when inserting it through a wall so that no

dust and dirt enter.

■

Use a good thread sealant for the sealing of the connections.

The sealant must be able to withstand the pressures and

temperatures of the system.

■

When using non-brass metallic piping, make sure to insulate

both materials from each other to prevent galvanic corrosion.

■

Because brass is a soft

material, use appropriate tooling

for connecting the water circuit.

Inappropriate tooling will cause

damage to the pipes.

■

Select piping diameter in relation to required water flow and

available external static pressure of the pump.

■

The minimum required water flow for the unit operation is

16 l/min. When the water flow is lower than this minimum value,

flow error

7H

will be displayed and the operation of the unit will

be stopped.

■

Never use Zn-coated parts in the water circuit. Excessive

corrosion of these parts may occur as copper piping is used in

the unit's internal water circuit.

■

When using a 3-way valve in the water circuit.

It is very important to guarantee full separation between

domestic hot water and floor heating water circuit.

■

When using a 3-way valve or a 2-way valve in the water circuit,

the maximum change over time of the valve shall be less than

60 seconds.

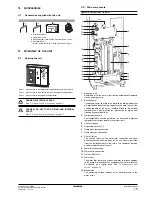

Checking the water volume and expansion vessel

pre-pressure

The unit is equipped with an expansion vessel of 10 litre which has a

default pre-pressure of 1 bar.

To assure proper operation of the unit, the pre-pressure of the

expansion vessel might need to be adjusted and the minimum and

maximum water volume must be checked.

1

Check that the total water volume in the installation, excluding

the internal water volume of the unit, is 20 l minimum. Refer to

"14. Technical specifications" on page 54

to know the internal

water volume of the unit.

(1) Be sure that the correct field settings are active or selected according to

the applicable tank type. See field settings in

"[4] Backup/booster heater

operation and space heating off temperature" on page 34

for more details.

(2) For tank without electrical booster heater (EKHTS), the backup heater will

be used in domestic water heating mode.

(3) Only applicable for tank with built-in electrical booster heater (EKHW*).

M

FCU1

FCU2

FCU3

8

M

FHL1

FHL2

FHL3

9

10 11

6

7

T

75

°

C

(EKHTS)

75

°

C

(EKHTS)

65

°

C

(EKHW*)

65

°

C

(EKHW*)

65

°

C

65

°

C

5

4

2

3

1

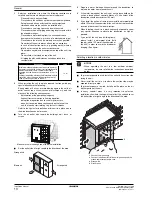

NOTICE

It is strongly recommended to install an additional filter on

the heating water circuit. Especially to remove metallic

particles from the field heating piping, it is advised to use a

magnetic or cyclone filter which can remove small

particles. Small particles can damage the unit and will not

be removed by the standard filter of the heat pump unit.

INFORMATION

In most applications this minimum water volume will have a

satisfying result.

In critical processes or in rooms with a high heat load

though, extra water volume might be required.