E(D/B)(H/L)Q011~016BB

Unit for air to water heat pump system

4PW67904-1 – 01.2011

Installation manual

26

Connection of the valve control cables

Valve requirements

■

Power supply: 230 V AC

■

Maximum running current: 100 mA

Procedure for wiring the 2-way valve

1

Using the appropriate cable, connect the valve control cable to

the X2M terminal as shown on the wiring diagram (inside of

door 2).

2

Fix the cable(s) with cable ties to the cable tie mountings to

ensure strain relief.

Procedure for wiring the 3-way valve

1

Using the appropriate cable, connect the valve control cable to

the appropriate terminals as shown on the wiring diagram

(inside of door 2).

2

Fix the cable(s) with cable ties to the cable tie mountings to

ensure strain relief.

Connection to a benefit kWh rate power supply

Electricity companies throughout the world work hard to provide

reliable electric service at competitive prices and are often authorized

to bill clients at benefit rates. E.g. time-of-use rates, seasonal rates,

Wärmepumpentarif in Germany and Austria, ... .

This equipment allows for connection to such benefit rate power

supply delivery systems.

Consult with the electricity company acting as provider at the site

where this equipment is to be installed to know whether it is

appropriate to connect the equipment in one of the benefit kWh rate

power supply delivery systems available, if any.

When the equipment is connected to such benefit kWh rate power

supply, the electricity company is allowed to:

■

interrupt power supply to the equipment for certain periods of

time;

■

demand that the equipment only consumes a limited amount of

electricity during certain periods of time.

The unit is designed to receive an input signal by which the unit

switches into forced off mode. At that moment, the compressor will

not operate.

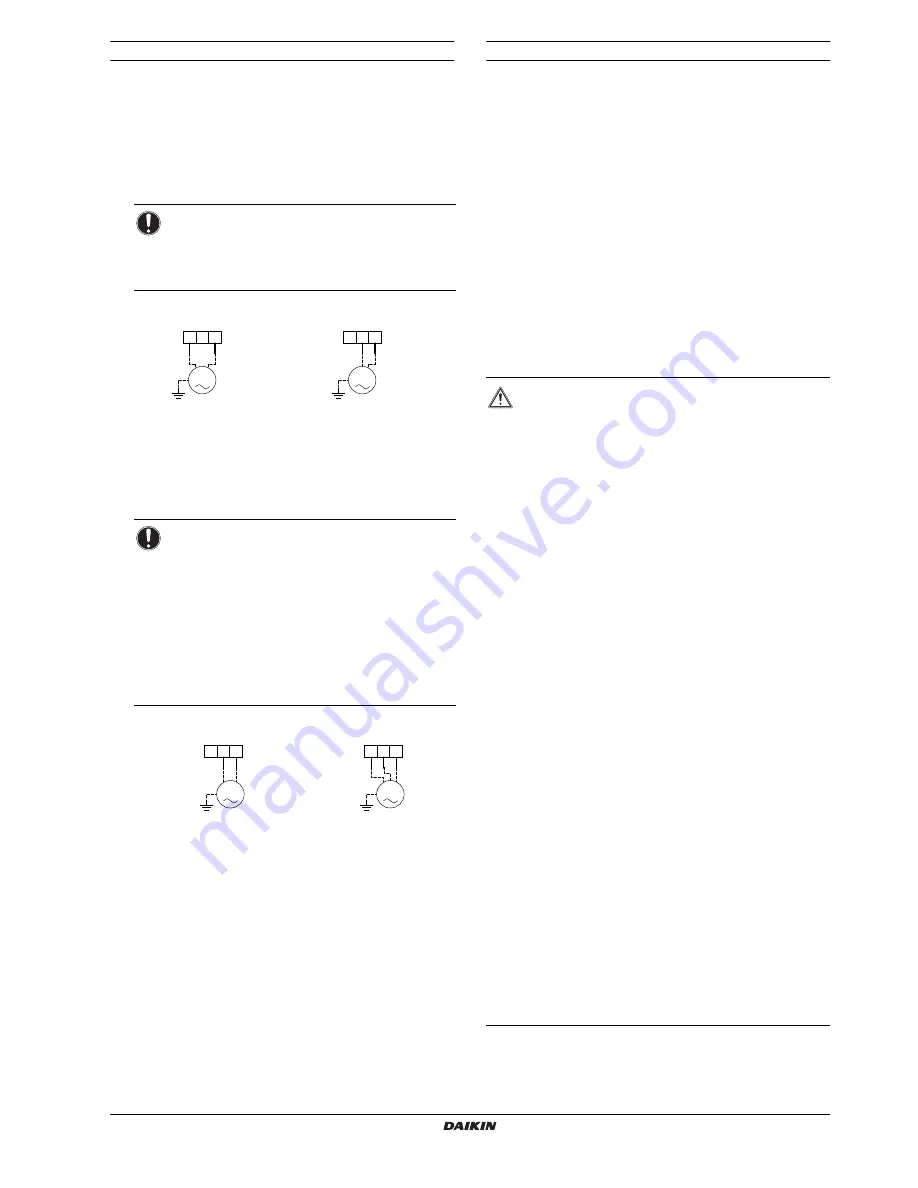

NOTICE

Wiring is different for a NC (normal closed) valve and

a NO (normal open) valve. Make sure to connect to

the correct terminal numbers as detailed on the wiring

diagram and illustrations below.

Normal closed (NC) 2-way valve

Normal open (NO) 2-way valve

NOTICE

Two types of 3-way valves can be connected. Wiring

is different for each type:

■

"Spring return 2-wire" type 3-way valve

The 3-way valve should be fitted as such that

when the 3-way valve is idle (not activated), the

space heating circuit is selected.

■

"SPST 3-wire" type 3-way valve

The 3-way valve should be fitted as such that when

terminal ports 9 and 10 are electrified, the domestic

hot water circuit is selected.

"Spring return 2-wire" valve

"SPST 3-wire" valve

NC

5

X2M

6

7

M

NO

5

6

X2M

7

M

9

X2M

8

10

M

9

X2M 8

10

M

CAUTION

For a benefit kWh rate power supply like illustrated

below as type 1 (allowed for all models)

■

If the benefit kWh rate power supply is of the type that

power supply is not interrupted, then control of the

unit is still possible. The controller, the expansion

vessel heater, plate heat exchanger heater and switch

box heater have power supply and the freeze

protection function can operate when required.

■

During the period that the benefit kWh rate is active

and power supply is continuous, then stand-by power

consumption is possible (PCB, controller, pump, ...).

■

If the benefit kWh rate is active for more than 2 hours,

backup heater operation can be required (part of the

freeze protection function, see

"Protecting the water

circuit against freezing" on page 19

). For this reason,

the backup heater shall be connected to a normal

kWh rate power supply and the correct setting [d-00]

must be selected. See

"[d] Benefit kWh rate power

supply/Local shift value weather dependent" on

page 42

.

For a benefit kWh rate power supply like illustrated

below as types 2 or 3

If during benefit kWh rate power supply, the main power

supply is shut off, and the normal kWh rate power supply is

not connected to 1-2, X11M (only allowed for EDL and EBL

models) then:

1.

the expansion vessel heater, plate heat exchanger

heater and switch box heater can not be controlled,

2.

the controller display will be blank + after 2 hours, the

real time clock of the controller will be reset,

3.

the freeze protection function (refer to

"Freeze

protection function" on page 35

) can not operate.

To overcome 1, 2 and 3 the unit should be connected to a

normal kWh rate power supply via 1-2 X11M to allow

continuous control and operation (e.g., pump, expansion

vessel heater, plate heat exchanger heater, switch box

heater, and freeze protection function).

The power supply (compressor compartment, X1M: L1, L2,

L3, N) interruption may not be longer than 2 hours to

guarantee to optimized startup condition for compressor.