Installation manual

49

E(D/B)(H/L)Q011~016BB

Unit for air to water heat pump system

4PW67904-1 – 01.2011

11.5. Underfloor heating screed dry-out program

This function allows the installer to define and automatically execute

an "underfloor heating screed dry-out" program.

The program is used to dry-out the screed of an underfloor heating

during the construction of a house.

Disclaimer

1.

Even though the program will execute automatically the different

programmed actions, the installer is responsible to check on

regular basis the good working of the setup.

2.

Please pay attention that the installer has full responsibility to

select the correct program that fits to the type of used screed for

the floor.

Field settings

Underfloor screed dry-out field settings:

■

[F-05] Action number selection

■

[F-06] Heating set point of selected action number [F-05]

■

[F-07] Time of selected action number [F-05] (steps of 12 hours)

■

[F-08] Underfloor heating screed dry-out program enabled

(1)/disabled (0)

■

[F-09] (Read only) Latest action number executed.

In case "underfloor heating screed dry-out program" is executed

successful then [F-09] has value 21.

Getting started

■

Each action is executed with a programmed heating set point for

a programmed time (steps of 12 hours).

■

A maximum of 20 different actions can be programmed.

■

The program is activated in the test run operation.

■

When the program is stopped by an error or an operation switch

off or a power failure, the

U3

error code will be displayed.

To resolve the error codes, see

"13.3. Error codes" on page 53

.

Procedure

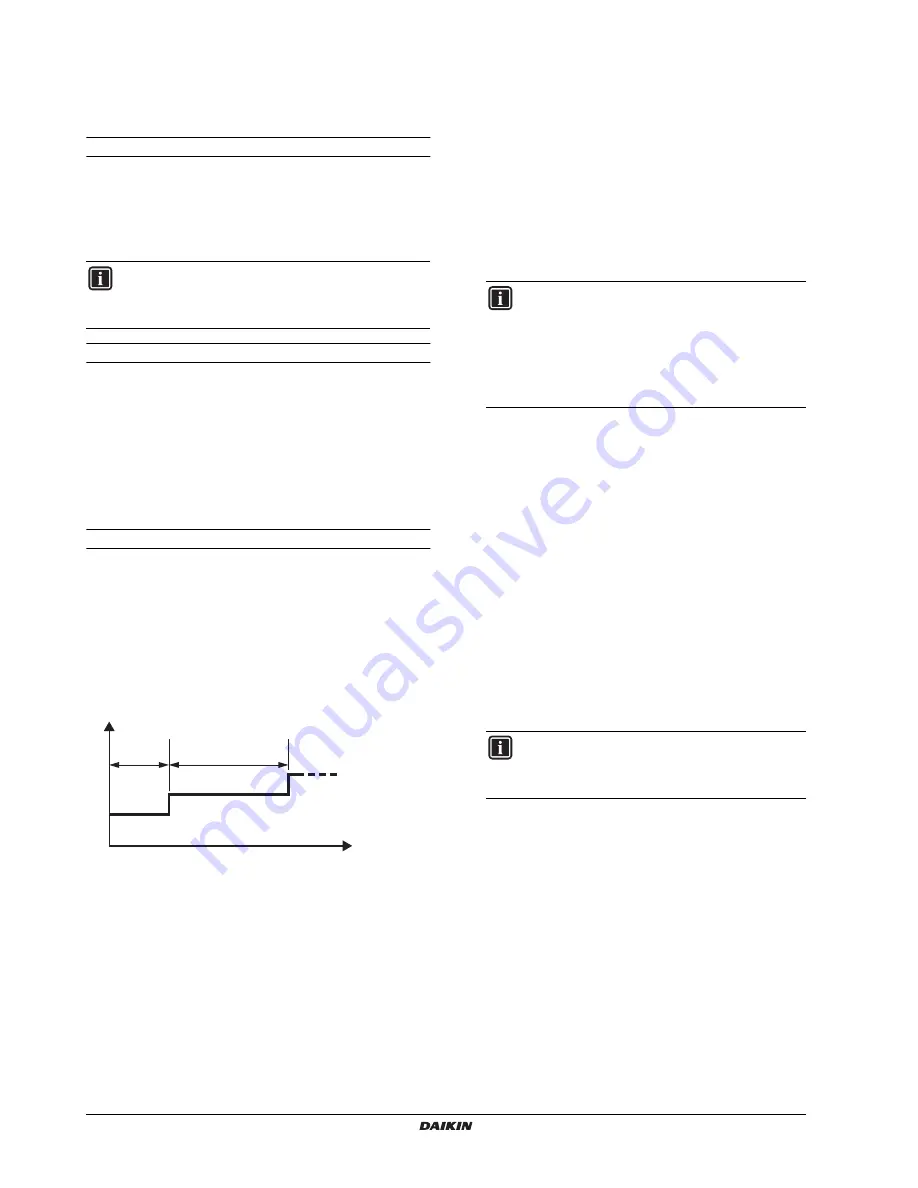

Example of program:

H Heating set point

t Time

(1) Action number 1

(2) Action number 2

1

Set field settings

■

The different actions are programmed as follows:

(refer to

"10.10. Field settings" on page 32

to know how to

change the field settings)

1 Set in [F-05] (Action number), the action to be programmed,

example 1.

Save the new value by pressing the

pr

button.

2 Set in [F-06] (Heating set point of selected action number

[F-05]), example 25°C.

Save the new value by pressing the

pr

button.

3 Set in [F-07] (Time of selected action number [F-05]),

example 24 hours.

Save the new value by pressing the

pr

button.

4 Repeat step 1 through 3 to program all the actions.

■

Consult the different actions to confirm good setting values

as follows:

(Refer to

"10.10. Field settings" on page 32

to know how to

change the field settings)

1 Set in [F-05] (Action number), the action to be consulted,

example 1.

Save the new value by pressing the

pr

button.

2 Consult [F-06] (Heating set point of selected number [F-05])

3 Consult [F-07] (Time of selected number [F-05]), example 24

hours.

4 Repeat step 1 through 3 to consult all the actions.

■

Enable the "underfloor heating screed dry-out program" as

follows:

1 Set in [F-08] (Underfloor heating screed dry-out program

enabled/disabled) to 1 (enabled).

2 When finished, press the

z

button to exit the FIELD SET

MODE.

2

Activate

1 Push the

z

button 4 times so the

t

icon will be

displayed.

2 To start the "Underfloor heating dry-out program" press the

y

button.

3 The "Underfloor heating dry-out program" will start and

display the action and temperature setting of action

number 1. The icon

e

is also displayed.

3

During activation

The underfloor heating dry-out program will automatically run

through all programmed actions.

4

End

1 When all actions are executed, the program will automatically

be stopped by switching off the unit and the

t

icon will be

disappeared.

2 When the (Underfloor heating dry-out program) has ended

successfully the [F-09] will have value 21.

INFORMATION

Benefit kWh rate power supply cannot be used in

combination with "underfloor heating screed dry-out

program". (In case [d-01] is enabled, [F-08] can not be set.)

[F-07]=24 h

[F-07]=48 h

[F-06]=25

°

C

[F-06]=35

°

C

(1)

(2)

(1)

(2)

t

H

INFORMATION

■

The not set actions will not be programmed

because these actions has time [F-07] equal to 0

hours as default.

■

So in case too many actions are programmed

and the quantity needs to be reduced, set the

time [F-07] to 0 hours of the actions that don’t

need to be executed.

INFORMATION

The activation of the "Underfloor heating screed

dry-out program" is similar to the starting the Test run

operation