12

13 ACHIEVING 1.4% AND 2.0% AIRFLOW LOW

LEAKAGE RATE

Ensure all the gaskets remain intact on all surfaces as shipped

with the unit. These surfaces are areas between the upper tie

plate and coil access panel, blower access and coil access

panels, and between the coil access and filter access pan

-

els. Ensure upon installation, that the plastic breaker cover

is sitting flush on the blower access panel and all access

panels are flush with each other and the cabinet. With these

requirements satisfied, the unit achieves less than 1.4%

airflow leakage @ 0.5 inch wc static pressure and less than

2% airflow leakage @1inch wc static pressure when tested

in accordance with ASHRAE Standard 193.

IMPORTANT

: After installing the heater kits, it is very import-

ant to seal the gap between the circuit breaker and the cover.

Putty paste or gasket can be used to seal the gap so that air

leakage can be minimized.

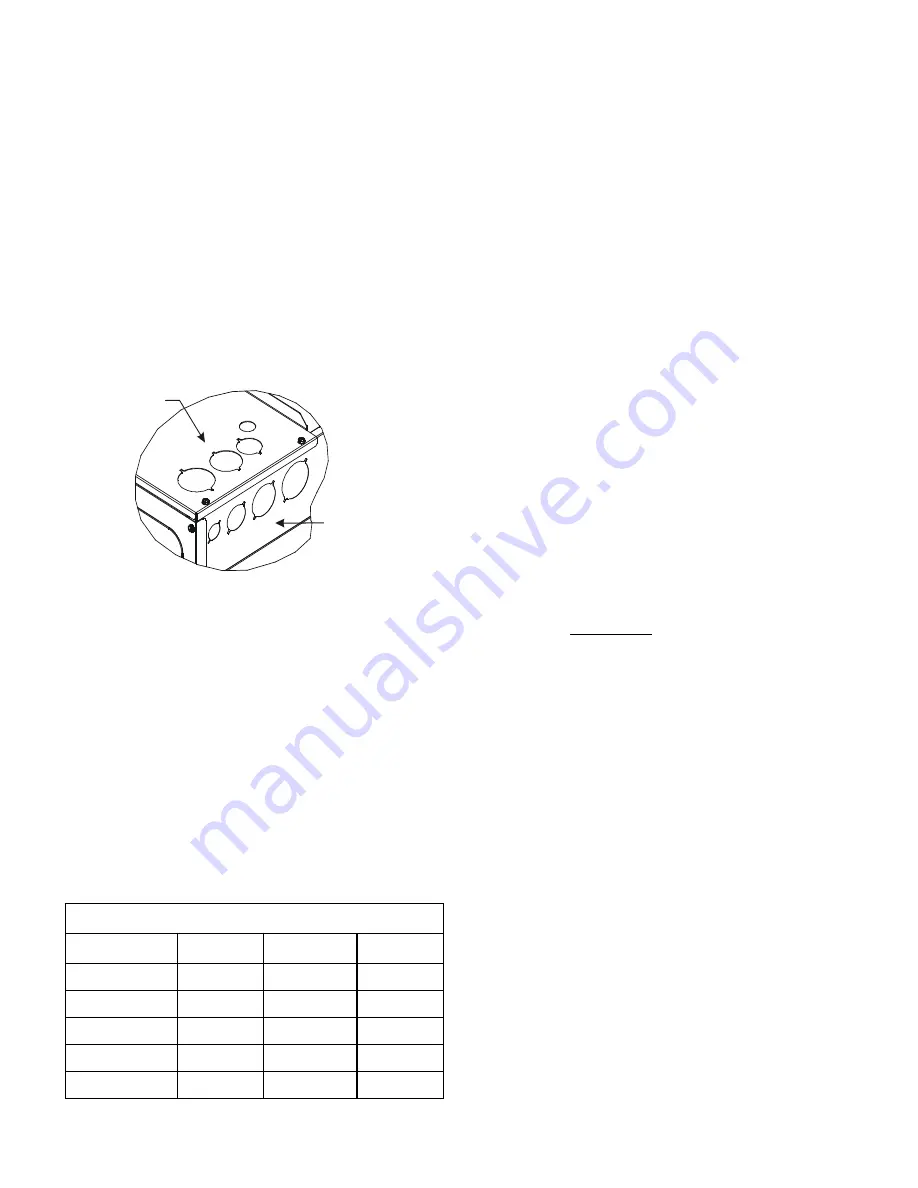

Side of

Cabinet

Top of

Cabinet

KNOCK-OUT FOR ELECTRICAL

CONNECTIONS

Figure 14

14 AIRFLOW TRIM

Indoor airflow can be trimmed up/down through the outdoor

unit user menu. For more detailed information, please refer

to the outdoor unit installation manual.

• To prevent condensation blow off, positive side trim

settings are allowed within the Maximum CFM listed

below. The CFM in this table intends actual measured

value at installation site. Do not refer to the CFM value

in the outdoor spec sheet, displayed in status menu

of communication thermostat, or the displayed LEDs

on the PCB, as there may be a tolerance difference

between displayed and actual measured.

Maximum Measured CFM Allowed

Up-Flow

Down-Flow

HZ-Flow

DV24FECB14

910

870

870

DV36FECC14

1450

1390

1390

DV42FECC14

1520

1450

1450

DV48FECD14

1590

1520

1520

DV60FECD14

1890

1800

1800

15 MISCELLANEOUS START-UP CHECKLIST

•

Prior to start-up, ensure that all electrical wires are prop-

erly sized and all connections are properly tightened.

•

All panels must be in place and secured. For Air Tight

application, gasket must be positioned at prescribed

locations to achieve 2% leakage.

•

Tubing must be leak free.

•

Condensate line must be trapped and pitched to allow

for drainage.

•

Auxiliary drain is installed when necessary and pitched

to allow for drainage.

•

Low voltage wiring is properly connected.

•

Unit is protected from vehicular or other physical dam-

age.

•

Return air is not obtained from, nor are there any return

air duct joints that are unsealed in, areas where there

may be objectionable odors, flammable vapors or prod

-

ucts of combustion such as carbon monoxide (CO),

which may cause serious personal injury or death.

IMPORTANT NOTE:

If thumb screws are used to access the

filter, ensure the washer installed on the screw behind the

access panel remains in place after re-installation.

NOTE: A removable plug connector is provided with the

control

to make thermostat wire connections. This plug

may be removed, wire connections made to the plug, and

replaced. It is

STRONGLY

recommended that you do not

connect multiple wires into a single terminal. Wire nuts are

recommended to ensure one wire is used for each terminal.

Failure to do so may result in intermittent operation.