12 Troubleshooting

Installer reference guide

83

ERGA04~08DAV3(A) + EHVH/X04+08S18+23DA

Daikin Altherma – Low temperature split

4P495248-1 – 2017.12

a

b

a

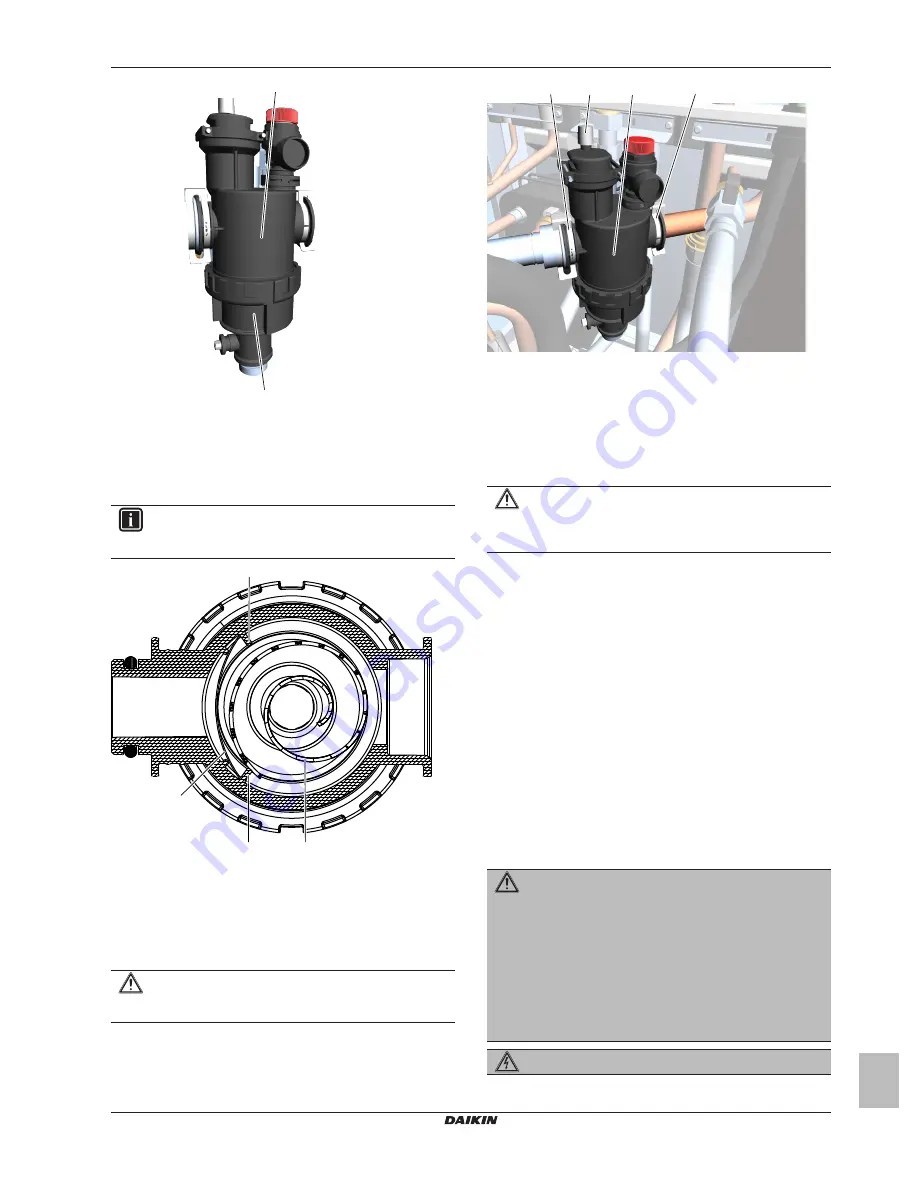

Bottom part to be unscrewed

b

Water filter housing

3

Remove the strainer and the rolled‑up filter from the water filter

housing and clean with water.

4

Install the cleaned rolled‑up filter and strainer in the water filter

housing.

INFORMATION

Correctly install the strainer in the water filter housing using

the protrusions.

a

b

c

c

a

Rolled‑up filter

b

Strainer

c

Protrusion

5

Install and properly tighten the bottom of the water filter

housing.

11.5.3

To install the water filter

CAUTION

Check the condition of the O-rings and replace if needed.

Apply water to the O-rings before installation.

1

Install the water filter in the correct location.

a

a

b

c

a

Clip

b

Water filter

c

Air purge valve

2

Install the 2 clips to fix the water filter to the water circuit pipes.

3

Make sure that the air purge valve of the water filter is in the

open position.

4

Open the valve (if equipped) of the water circuit towards the

expansion vessel.

CAUTION

Make sure to open the valve (if equipped) towards the

expansion vessel, otherwise the overpressure will be

generated.

5

Open the stop valves and add water to the water circuit if

needed.

12

Troubleshooting

12.1

Overview: Troubleshooting

This chapter describes what you have to do in case of problems.

It contains information about:

▪ Solving problems based on symptoms

▪ Solving problems based on error codes

Before troubleshooting

Carry out a thorough visual inspection of the unit and look for

obvious defects such as loose connections or defective wiring.

12.2

Precautions when troubleshooting

WARNING

▪ When carrying out an inspection on the switch box of

the unit, ALWAYS make sure that the unit is

disconnected from the mains. Turn off the respective

circuit breaker.

▪ When a safety device was activated, stop the unit and

find out why the safety device was activated before

resetting it. NEVER bridge safety devices or change

their values to a value other than the factory default

setting. If you are unable to find the cause of the

problem, call your dealer.

DANGER: RISK OF ELECTROCUTION

Final English - Tanslations in progress