EKHBH/X008BB

Indoor unit for air to water heat pump system

4PW62570-1A – 01.2011

Installation manual

8

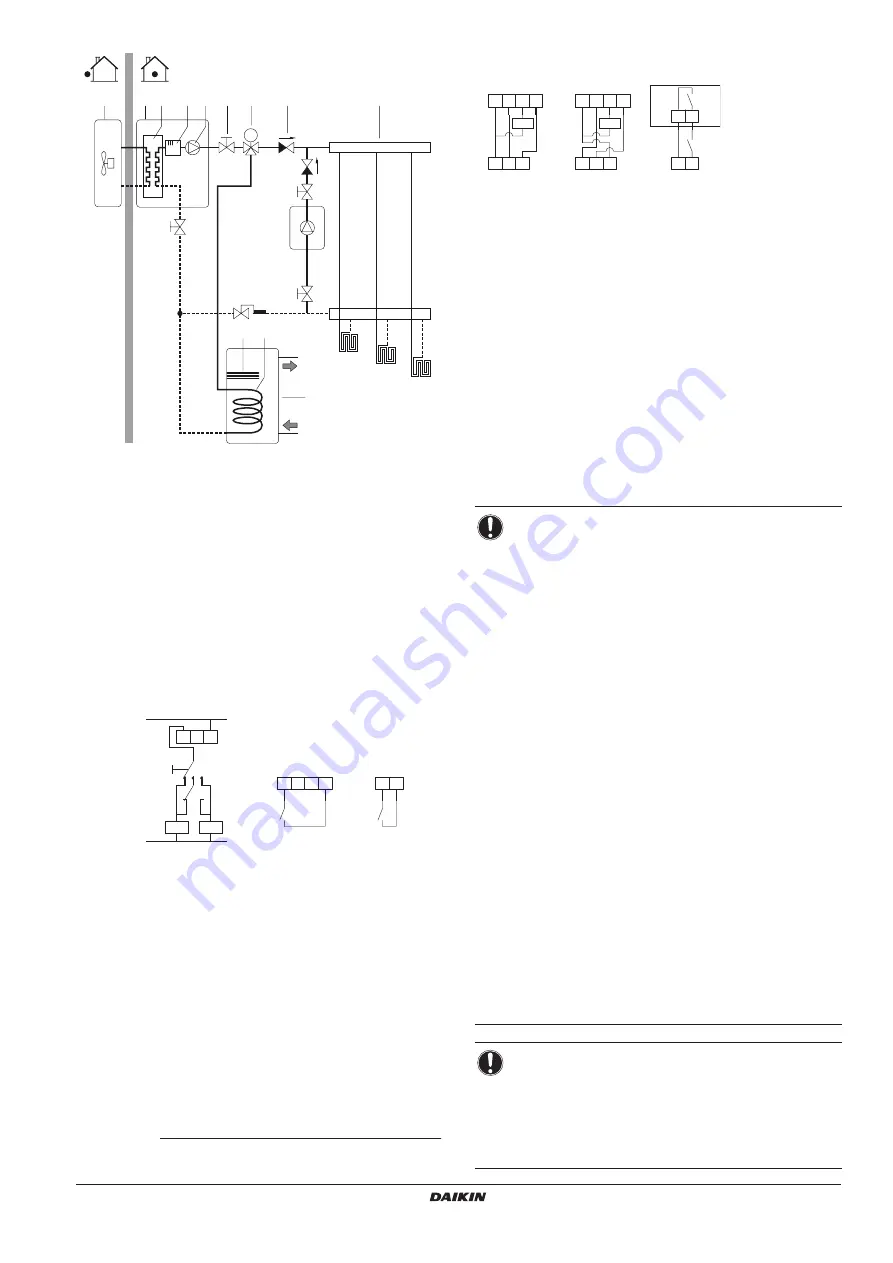

1

Outdoor unit

2

Indoor unit

3

Heat exchanger

4

Backup heater

(1)

5

Pump

6

Shut-off valve

7

Motorised 3-way valve (delivered with domestic hot water

tank)

8

Non-return valve (field supply)

9

Shut-off valve (field supply)

10

Collector (field supply)

11

Boiler (field supply)

12

Aquastat valve (field supply)

13

Domestic hot water tank (optional)

14

Booster heater

(2)

15

Heat exchanger coil

FHL1...3

Floor heating loop

Field wiring configuration A

B

TI

Boiler thermostat input

A

Auxiliary contact (normal closed)

H

Heating demand room thermostat (optional)

K1A

Auxiliary relay for activation of EKHB* unit (field supply)

K2A

Auxiliary relay for activation of boiler (field supply)

Field wiring configuration B

B

TI

Boiler thermostat input

C

Cooling demand room thermostat (optional)

H

Heating demand room thermostat (optional)

Com

Common room thermostat (optional)

K1A

Auxiliary relay for activation of boiler unit (field supply)

KCR

Permission signal for the auxiliary boiler

Operation

■

Configuration A

When the room thermostat requests heating, either the EKHB*

unit or the boiler starts operating, depending on the position of

the auxiliary contact (A).

■

Configuration B

When the room thermostat requests heating, either the EKHB*

unit or the boiler starts operating, depending on the outdoor

temperature (status of "permission signal for the auxiliary

boiler").

When the permission is given towards the boiler, the space

heating operation by the EKHB* unit will be automatically

switched off.

For more details see field setting [C-02~C-04].

(1) For tank without electrical booster heater (EKHTS), the backup heater will

be used in domestic water heating mode.

(2) Only applicable for tank with built-in electrical booster heater (EKHW*).

M

FHL1

FHL2

FHL3

8

8

9

9

12

11

6

10

4

5

3

2

1

6

7

13

14 15

1

2

3

4

K1A

K1A

K2A

X Y

K2A

BTI

L

N

EKHB*/auto

/

Boiler

A

EKHB*

X2M

H

Com

NOTICE

■

Configuration A

Make sure that auxiliary contact (A) has sufficient

differential or time delay so as to avoid frequent

changeover between the EKHB* unit and the boiler. If

the auxiliary contact (A) is an outdoor temperature

thermostat, make sure to install the thermostat in the

shade, so that it is not influenced or turned ON/OFF

by the sun.

Configuration B

Make sure that the bivalent hysteresis [C-04] has

sufficient differential to avoid frequent changeover

between the EKHB* unit and the boiler. As the

outdoor temperature is measured via the outdoor unit,

air thermistor make sure to install the outdoor unit in

the shade, so that it is not influenced by the sun.

Frequent switching may cause corrosion of the boiler

in an early stage. Contact the manufacturer of the

boiler.

■

During heating operation of the EKHB* unit, the unit

will operate so as to achieve the target leaving water

temperature as set on the user interface. When

weather dependent operation is active, the water

temperature is determined automatically depending

on the outdoor temperature.

During heating operation of the boiler, the boiler will

operate so as to achieve the target leaving water

temperature as set on the boiler controller.

Never set the target leaving water temperature set

point on the boiler controller above 55°C.

■

Make sure to only have 1 expansion vessel in the

water circuit. An expansion vessel is already

premounted in the Daikin indoor unit.

NOTICE

Make sure to configure the DIP switch SS2-3 on the PCB

of the EKHB* switch box correctly. Refer to

thermostat installation configuration" on page 24

For configuration B: Make sure to configure the field

settings [C-02, C-03 and C-04] correctly. Refer to

X1 X2

X Y

K1A

KCR

EKRP1HB*

BTI

1

2

3

4

H C

Com

K1A

EKHB*

X2M

EKRTR*

1

2

3

4

C

Com

H

K1A

EKHB*

X2M

EKRTW*