Installation manual

19

EKHBH/X008BB

Indoor unit for air to water heat pump system

4PW62570-1A – 01.2011

7.3.

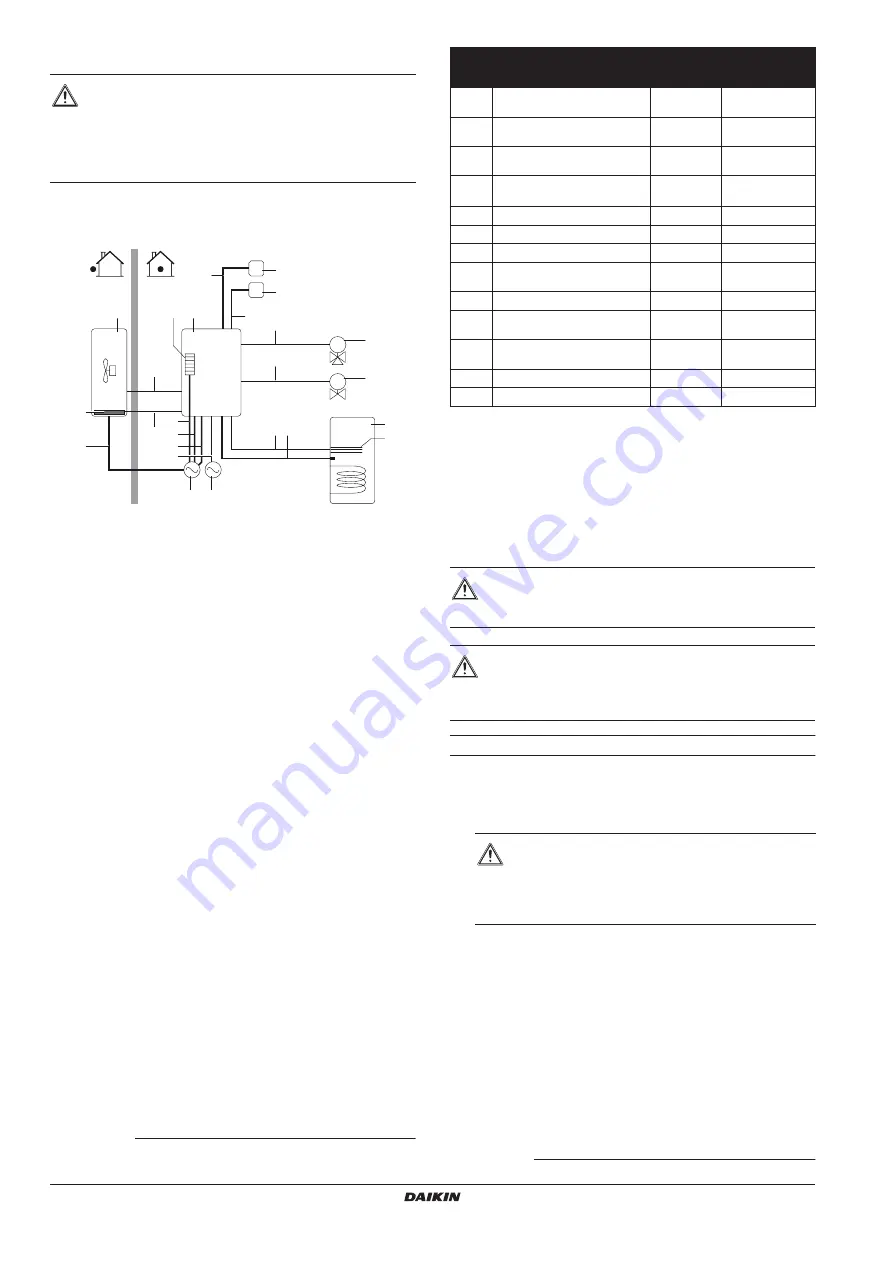

System overview of field wiring

The illustration below gives an overview of the required field wiring

between several parts of the installation. Refer also to

application examples" on page 5

A

Single power supply for outdoor unit, backup heater and

booster heater

B

Outdoor unit

C

Bottom plate heater

D

Backup heater

(1)

E

Indoor unit

F

Room thermostat (optional)

G

3-way valve for domestic hot water tank (optional)

H

2-way valve for cooling mode (field supply)

I

Domestic hot water tank (optional)

J

Booster heater

(2)

K

User interface (digital controller)

L

Power supply (normal kWh rate power supply: only in case

of benefit kWh rate power supply installation)

Field wiring guidelines

■

Most field wiring on the indoor unit side is to be made on the

terminal block inside the switch box. To gain access to the

terminal block, remove the indoor unit cover and switch box

service panel, see

"5.1. Opening the indoor unit" on page 10

■

Cable tie mountings are provided at the bottom of the switch

box. Fix all cables using cable ties (field supply).

■

A dedicated power circuit is required for the backup heater.

■

Installations equipped with a domestic hot water tank (optional),

require a dedicated power circuit for the

booster heater

(3)

.

Please refer to the domestic hot water tank installation manual.

WARNING

■

Switch off the power supply before making any

connections.

■

All field wiring and components must be installed by a

licensed electrician and must comply with the

applicable legislation.

(1) For tank without electrical booster heater (EKHTS), the backup heater will

be used in domestic water heating mode.

(2) Only applicable for tank with built-in electrical booster heater (EKHW*).

T

I

M

M

B

D

2

6

12

7

8 9

E

A

L

3

F

K

I

C

J

H

G

1

10

11

13

4

5

Item

Description

Required

number of

conductors

Maximum

running current

1

Power supply cable for outdoor

unit

2+GND

(a)

(a) Refer to nameplate on outdoor unit.

2

Indoor unit power supply and

communication cable

3+GND

(b)

(b) Cable section 2.5 mm

2

3

Power cable for bottom plate

heater

(c)

(c) Bottom plate heater cable is only applicable in combination with ERLQ or

in case of optional EKBPHT kit.

2

(d)

(d) Minimum cable section 0.75 mm

2

4

Power supply cable for backup

heater

2+GND or

3+GND

(e)

(e) See table under

"Connection of the backup heater power supply" on page 20

5

Room thermostat cable

3 or 4

100 mA

6

3-way valve control cable

2+GND

100 mA

7

2-way valve control cable

2+GND

100 mA

8

Booster heater power supply

and thermal protection cable

(f)

(f)

Only applicable for tank with built-in electrical booster heater (EKHW*).

4+GND

9

Thermistor cable

2

(g)

(g) The thermistor and connection wire (12 m) are delivered with the domestic hot

water tank.

10

Booster heater power supply

cable

2+GND

13 A

11

Benefit kWh rate power supply

cable (voltage free contact)

2

(h)

(h) Cable section 0.75 mm

2

till 1.25 mm

2

, maximum length: 50 m.

Voltage free contact shall ensure the minimum applicable load of 15 V DC,

10 mA.

12

User interface cable

2

(i)

(i)

Cable section 0.75 mm

2

till 1.25 mm

2

, maximum length: 500 m.

13

Normal kWh rate power supply

2+GND

CAUTION

Select all cables and wire sizes in accordance with the

applicable legislation.

WARNING

After finishing the electric work, confirm that each electric

part and terminal inside the electric parts box is connected

securely.

WARNING

Switch off all power supply – i.e. outdoor unit power

supply and backup heater and domestic hot water

tank power supply (if applicable) – before removing

the switch box service panel.

(3) Only applicable for tank with built-in electrical booster heater (EKHW*).