Installation manual

7

EKHBRD011~Y1

Indoor unit for air to water heat pump system

4PW54465-1C

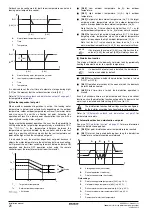

Switch box main components

V1 unit types (1-phase)

Y1 unit types (3-phase)

1.

Main PCB

The main PCB (Printed Circuit Board) controls the functioning of

the unit.

2.

Control PCB

3.

Inverter PCB

4.

Inverter control PCB (only Y1)

5.

QA PCB (only V1)

6.

Filter PCB

7.

Digital I/O PCB (optional)

8.

Demand PCB (optional)

9.

Terminal block X1M

Main terminal block which allows easy connection of field wiring

for power supply.

10. Terminal block X3M

Field wiring terminal block for DC connections.

11. Terminal block X2M

Field wiring terminal block for AC connections.

12. DC connector X1Y

13. Pump connector X2Y

14. AC connector X3Y

15. Cable tie mountings

The cable tie mountings allow to fix the field wiring with cable

ties to the switch box to ensure strain relief.

16. Power wiring entry

17. AC field wiring entry

18. DC field wiring entry

19. Compressor cable entry

20. Interface relay K1A

21. Wiring bridges

22. Fuse F1 (only Y1)

23. Fuse F2 (only Y1)

Functional diagram

8

18

12

20

13

2

3

1

19

5

10

14

11

17

16

15

21

6

9

7

15

15

8

18

12

20

13

2

3

1

19

10

7 14 11 17 16

21

9

23

4

15

15

22 6

15

NOTE

The electrical connection diagram can be found on the

inside of the switch box cover.

1

Outdoor unit

16

Fill valve (field supply)

2

Indoor unit

17

Shut-off valve water inlet

3

Refrigerant-refrigerant

heat exchanger

18

Shut-off valve water outlet

19

Domestic hot water tank

(optional)

4

Accumulator

5

Compressor

20

Motorized 3-way valve

(optional)

6

Service port

7

Refrigerant-water heat

exchanger

21

Thermal cut-out (Q2L)

22

High pressure switch (S1PH)

8

Drain valve

23

High pressure sensor (B1PH)

9

Electronic expansion

valve

24

Low pressure sensor (B1PL)

25

Discharge thermistor (R6T)

10

Pressure relief valve

26

Leaving water thermistor (R5T)

11

Pump

27

Returning water thermistor

(R4T)

12

Air purge valve

13

Manometer

28

Liquid thermistor R134a (R7T)

14

Expansion vessel

29

Liquid thermistor R410A (R3T)

15

Water filter

30

2-way valve

M

1

2

29

3

8

9

28

12

27

11

26

6

13

10

4

7

14

15

17

19

16

25

30

5

6

22

23

24

21

20

18

Summary of Contents for EKHBRD-AY1

Page 43: ...V1 Y1 NOTES 5 5...

Page 44: ...4PW54465 1C Copyright Daikin...