6 Electrical installation

Installation manual

17

EL23E

Daikin Altherma 3 R MT F

4P708476-1 – 2023.03

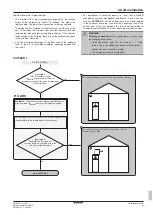

NOTICE

Differential

pressure bypass valve

(delivered as

accessory). We recommend to install the differential

pressure bypass valve in the space heating water circuit.

▪ Mind the minimum water volume when choosing the

installation location of the differential pressure bypass

valve (at the indoor unit, or at the collector). See

"5.3.1 To check the water volume and flow rate"

15].

▪ Mind the minimum flow rate when adjusting the

differential pressure bypass valve setting. See

"5.3.1 To check the water volume and flow rate"

and

"8.2.1 To check the minimum flow rate"

NOTICE

If you install this unit as a single-zone application, then:

Setup.

Install a bypass between the space heating water

inlet and outlet of the additional zone (=direct zone). Do

NOT interrupt the water flow by closing the shut-off valves.

a

a

Bypass

Configuration.

Set field setting [7-02]=0 (

Number of

zones

=

Single zone

).

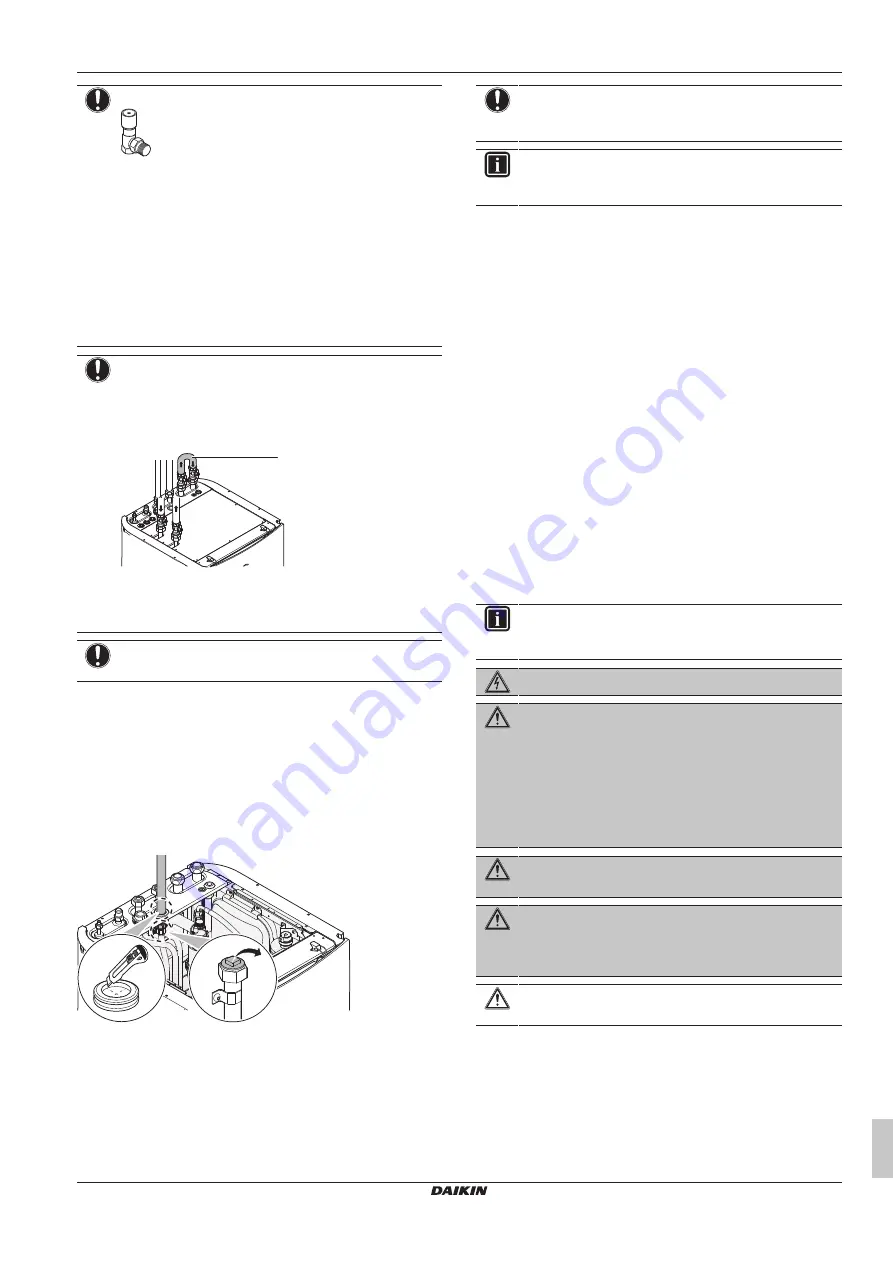

NOTICE

Install air purge valves at all local high points.

5.4.2

To connect the recirculation piping

Prerequisite:

Only required if you need recirculation in your system.

1

Remove the top panel from the unit, see

2

Cut out the rubber grommet on top of the unit, and remove the

stop. The recirculation connector is placed below the hole.

3

Route the recirculation piping through the grommet and connect

it to the recirculation connector.

4

Reattach the top panel.

5.4.3

To fill the water circuit

To fill the water circuit, use a field supply filling kit. Make sure you

comply with the applicable legislation.

NOTICE

Pump.

To prevent blocking of the pump rotor, commission

the unit as quickly as possible after filling the water circuit.

INFORMATION

Make sure both air purge valves (one on the magnetic filter

and one on the backup heater) are open.

5.4.4

To fill the domestic hot water tank

1

Open every hot water tap in turn to purge air from the system

pipe work.

2

Open the cold water supply valve.

3

Close all water taps after all air is purged.

4

Check for water leaks.

5

Manually operate the field-installed pressure relief valve to

ensure a free water flow through the discharge pipe.

5.4.5

To insulate the water piping

The piping in the complete water circuit MUST be insulated to

prevent condensation during cooling operation and reduction of the

heating and cooling capacity.

If the temperature is higher than 30°C and the humidity is higher

than RH 80%, the thickness of the insulation materials should be at

least 20 mm to prevent condensation on the surface of the

insulation.

6

Electrical installation

INFORMATION

This unit is a heating only model. Therefore, all references

to cooling in this document are NOT applicable.

DANGER: RISK OF ELECTROCUTION

WARNING

▪ All wiring MUST be performed by an authorised

electrician and MUST comply with the applicable

national wiring regulation.

▪ Make electrical connections to the fixed wiring.

▪ All components procured on-site and all electrical

construction MUST comply with the applicable

legislation.

WARNING

ALWAYS use multicore cable for power supply cables.

WARNING

If the supply cord is damaged, it MUST be replaced by the

manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

CAUTION

Do NOT push or place redundant cable length into the unit.